A kind of preparation method of microcrystalline ceramic backplane based on 5g communication signal without shielding

A technology of microcrystalline ceramics and communication signals, which is applied in the direction of telephone communication, branch office equipment, telephone structure, etc., can solve the problems such as the inability to realize the net size molding of the back plate material, achieve excellent mechanical shock resistance, low preparation cost, and preparation The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

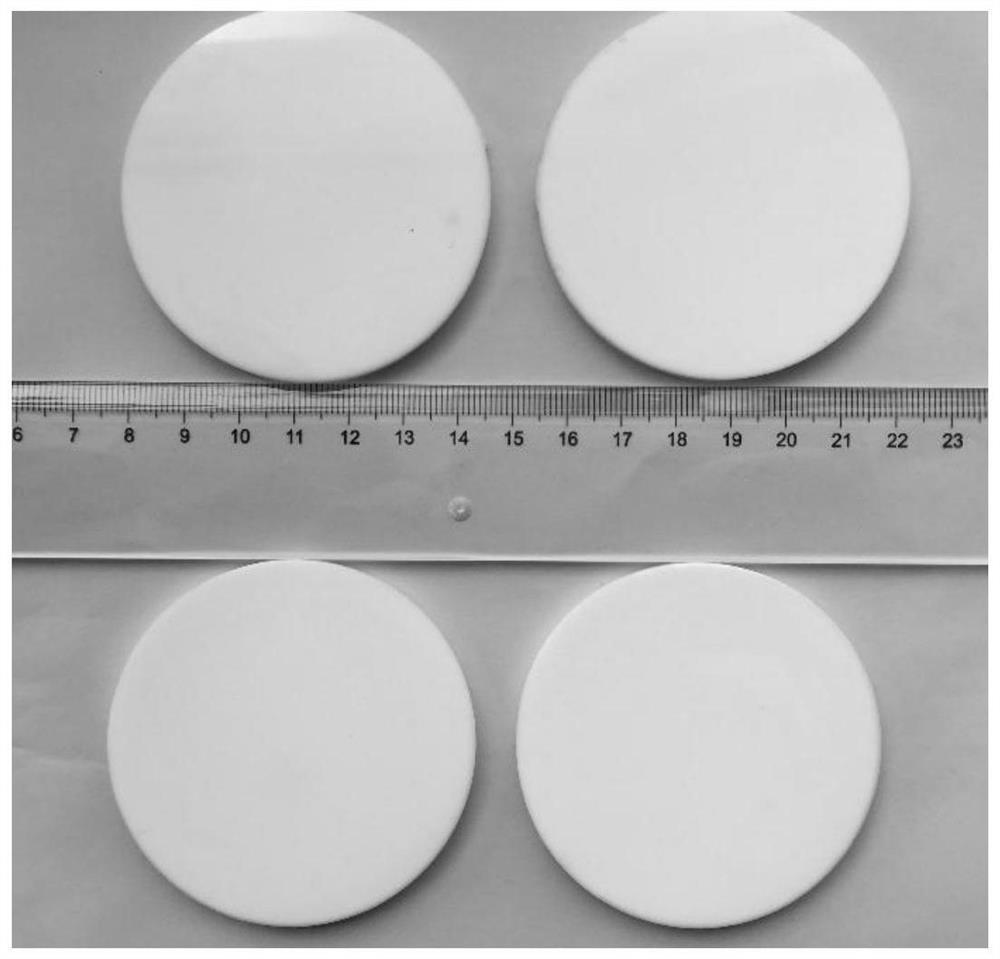

[0030] A method for preparing a microcrystalline ceramic backplane without shielding based on 5G communication signals, the specific steps are as follows:

[0031] (1) Weigh high-purity Y separately 2 o 3 Powder, high purity Gd 2 o 3 Powder and high purity ZrO 2 powder, and added to the nylon ball mill jar, where Y 2 o 3 Adding amount is Y 2 o 3 with Gd 2 o 3 0.9wt.% of the mixed powder mass, ZrO 2 Adding amount is Y 2 o 3 with Gd 2 o 3 1wt.% of the mass of the mixed powder;

[0032] (2) Add dispersant NP-10 and solvent to the mixed powder obtained in step (1) to carry out drum milling. The material of the ball is zirconia, the diameter of the ball is 30mm, the speed of ball milling is 200r / min, and the time of ball milling is 20h , the solid content of adjustment slurry is 52wt.%; Described dispersant add-on is 1wt.% of mixed raw material powder gross mass, and solvent is the mixed solution of methyl ethyl ketone and dehydrated alcohol (the quality of methyl et...

Embodiment 2

[0044] A method for preparing a microcrystalline ceramic backplane without shielding based on 5G communication signals, the specific steps are as follows:

[0045] (1) Weigh high-purity Y separately 2 o 3 Powder, high purity Gd 2 o 3 Powder and high purity ZrO 2 powder, and added to the nylon ball mill jar, where Y 2 o 3 Adding amount is Y 2 o 3 with Gd 2 o 3 0.1wt% of the total mass of mixed powder, ZrO 2 Adding amount is Y 2 o 3 with Gd 2 o 3 2wt.% of the total mass of mixed powder;

[0046] (2) add dispersant herring oil and solvent to the mixed powder obtained in step (1) and carry out drum milling, the ball material is zirconia, the ball diameter is 50mm, the ball milling speed is 80r / min, and the ball milling time is 36h, The solid content of adjustment slurry is 45wt.%; The addition of described dispersant is 0.4wt.% of the total mass of mixed raw material powder, and solvent is the mixed solution of methyl ethyl ketone and dehydrated alcohol (the quality...

Embodiment 3

[0054] A method for preparing a microcrystalline ceramic backplane without shielding based on 5G communication signals, the specific steps are as follows:

[0055] (1) Weigh high-purity Y separately 2 o 3 Powder, high purity Gd 2 o 3 Powder and high purity ZrO 2 powder, and added to the nylon ball mill jar, where Y 2 o 3 Adding amount is Y 2 o 3 with Gd 2 o 3 0.5wt.% of the total mass of mixed powder, ZrO 2 Adding amount is Y 2 o 3 with Gd 2 o 3 0.1wt.% of the total mass of mixed powder;

[0056] (2) adding dispersant castor oil and solvent to the mixed powder obtained in step (1) and carrying out drum milling, the ball material is zirconia, the ball diameter is 60mm, the ball milling speed is 300r / min, and the ball milling time is 15h, The solid content of adjustment slurry is 55wt.%; The 1.5wt.% of described dispersant addition is the total mass of mixed raw material powder, and solvent is the mixed solution of methyl ethyl ketone and dehydrated alcohol (the q...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com