Self-heating metal hydride hydrogen storage system and method for charging and discharging hydrogen

A hydride and self-heating technology, applied in the field of hydrogen storage systems, can solve problems such as insufficient volumetric energy density, difficulty in management, and high safety factor, and achieve the effect of solving the difficulty of starting at low temperature and preventing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

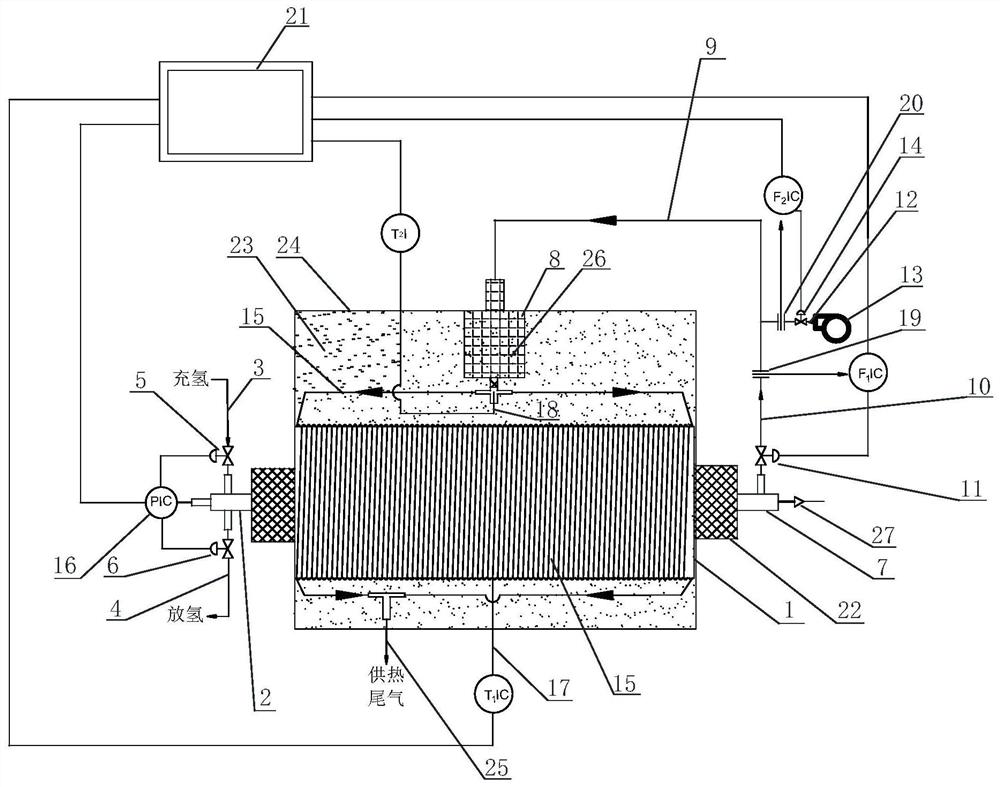

[0034] With reference to the accompanying drawings, a self-heating metal hydride hydrogen storage system includes a hydrogen storage system and a hydrogen catalytic combustion heating system for heating the hydrogen storage system. The hydrogen storage system includes a hydrogen storage tank 1, in which a metal hydride hydrogen storage material is installed, the hydrogen storage tank 1 is arranged horizontally, and a hydrogen charging and discharging port 2 is provided at one end of the hydrogen storage tank 1 , the hydrogen charging and discharging port 2 is connected to the hydrogen charging pipeline 3 and the hydrogen discharging pipeline 4. A first control valve 5 is set on the hydrogen charging pipeline 3 , and a second control valve 6 is set on the hydrogen discharge pipeline 4 . The other end of the hydrogen storage tank 1 is provided with a hydrogen outlet port 7 for supplying hydrogen to the hydrogen catalytic combustion heating system.

[0035] The hydrogen catalyti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com