Busbar for high-safety power battery module and manufacturing method of busbar

A power battery and busbar technology, which is applied to battery components, secondary batteries, circuits, etc., can solve the problems of unable to cut off the circuit in time, thermal runaway of the module, and no safety protection, so as to avoid thermal runaway and over-control Accurate stream size and improved security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

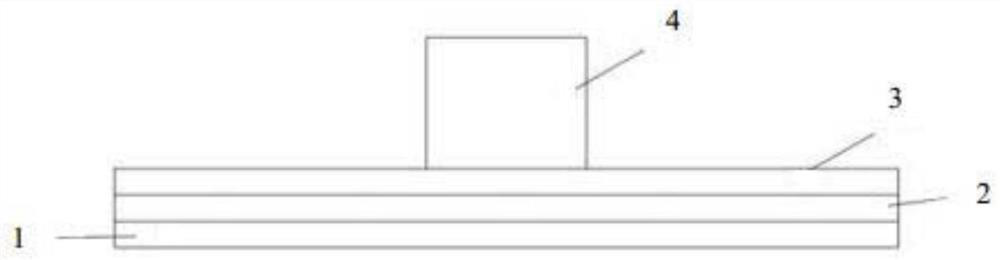

[0046] This embodiment provides a method for preparing a busbar. Such as figure 1 As shown, the bus bar includes a base material 1 , a semiconductor layer 2 of a PTC thermistor, a metal layer 3 and a terminal 4 . The preparation of the busbar includes:

[0047]Substrate production: According to the ratio of PE: SP = 95%: 5%, melting and mixing molding is carried out to make a thickness of 200 μm and a conductivity of 10 -8 s / m substrate.

[0048] Production of the PTC coating material: According to the weight ratio of PE: yttrium oxide: barium titanate = 74%: 2%: 24%, melting and mixing are carried out to prepare a uniform coating material.

[0049] PTC coating: Corona treatment is carried out on the above substrate, and then the prepared PTC coating material is coated on the substrate by electrostatic spraying to form the semiconductor layer of the PTC thermistor, the semiconductor layer of the PTC thermistor The thickness is 100 μm.

[0050] Plating metal layer: use mag...

Embodiment 2

[0054] This embodiment provides a method for preparing a busbar. Such as figure 1 As shown, the bus bar includes a base material 1 , a semiconductor coating 2 of a PTC thermistor, a metal layer 3 and a terminal 4 . The preparation of the busbar includes:

[0055] Substrate production: According to the ratio of PE: SP = 97.5%: 2.5%, perform mixed molding to make a thickness of 300 μm and a conductivity of 10 -9 s / m substrate.

[0056] Production of PTC coating material: According to the ratio of PE: yttrium oxide: barium titanate = 74%: 2%: 24%, melting and mixing are carried out to make a uniform coating material.

[0057] PTC coating: Corona treatment is carried out on the above substrate, and then the prepared PTC coating material is coated on the substrate by electrostatic spraying to form the semiconductor layer of the PTC thermistor, the semiconductor layer of the PTC thermistor The thickness is 200 μm.

[0058] Plating metal layer: use magnetron sputtering to plate ...

Embodiment 3

[0062] This embodiment provides a method for preparing a bus bar. Such as figure 1 As shown, the bus bar includes a base material 1 , a semiconductor coating 2 of a PTC thermistor, a metal layer 3 and a terminal 4 . The preparation of the busbar includes:

[0063] Substrate production: According to the ratio of PP: SP = 95%: 5%, perform mixed molding to make a thickness of 200 μm and a conductivity of 10 -8 s / m substrate.

[0064] Production of PTC coating materials: According to the ratio of PE: yttrium oxide: barium titanate = 80%: 3%: 17%, melting and mixing are carried out to make a uniform coating material.

[0065] PTC coating: Corona treatment is carried out on the above substrate, and then the prepared PTC coating material is coated on the substrate by electrostatic spraying to form the semiconductor layer of the PTC thermistor, the semiconductor layer of the PTC thermistor thickness

[0066] Plating metal layer: A layer of metal copper is plated on the semiconduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com