A full process method of laser welding based on icme

A technology of laser welding and process method, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as affecting welding quality, consuming manpower and material resources, and large workload, saving time and labor costs, saving costs, Thermal crack reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

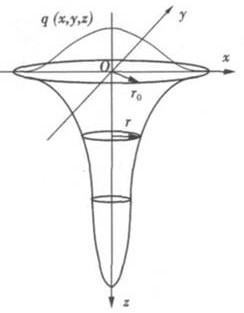

[0028] Such as figure 1 As shown, an ICME-based laser welding full-process method includes the following steps:

[0029] a. Calculate the amount of deposition according to the shape of the groove and the number of welding layers, and obtain the diameter of the welding wire and the speed of the wire feeding;

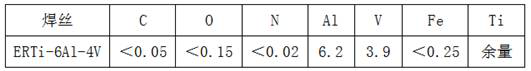

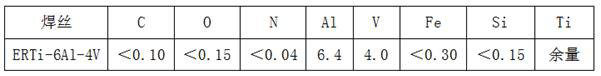

[0030] b. Calculate the phase diagram according to the service conditions of the components, the database of titanium alloy materials, the properties of the welded joints and the transformation behavior, and obtain the composition of the welding wire;

[0031] c. Establish a welding structure finite element model according to the wire feeding speed and welding wire composition, select the laser welding heat source model, simulate the thermal field and flow field for TC4 titanium alloy laser welding, and calculate different welding parameters;

[0032] d. Select the process parameter group according to the welding parameters;

[0033] e. Experimental verification is car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com