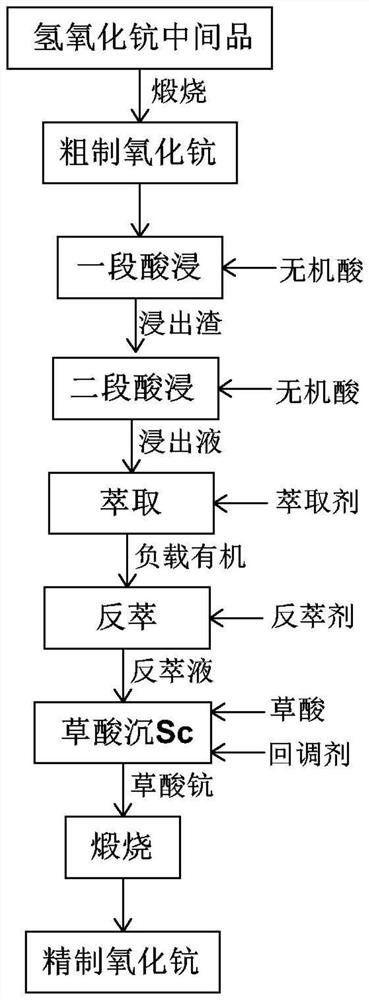

Method for purifying and refining high-purity scandium oxide from scandium hydroxide intermediate product

A technology of scandium hydroxide and scandium oxide, which is applied in the direction of scandium oxide/scandium hydroxide, rare earth metal oxides/hydroxides, rare earth metal compounds, etc. High-purity scandium oxide process is cumbersome and other problems, to achieve the effect of shortening the process flow, simple operation, and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Calcining 1000g scandium hydroxide intermediate product at 800°C for 2h to obtain crude scandium oxide.

[0032] Slurry the crude scandium oxide with water to obtain a slurry, add hydrochloric acid to the slurry to adjust the pH to 1.5, maintain the pH at 1.5 and react for 3 hours, filter to obtain the first filter residue, wash the first filter residue with pure water to obtain a leaching residue.

[0033] Put the first-stage leaching residue into a hydrochloric acid solution with a hydrogen ion concentration of 6 mol / L, react at 90°C for 5 hours, and filter to obtain a scandium-rich second-stage leaching solution.

[0034] The second-stage leachate is extracted and phase-separated with extractant P350 to obtain a scandium-rich organic phase; the volume concentration of the extractant P350 is 40%, and the second-stage leachate is extracted with extractant P350 and the diluent used for phase separation is sulfur kerosene. The extraction ratio is O / A=1:1, and the extrac...

Embodiment 2

[0039] Calcining 1000g scandium hydroxide intermediate product at 800°C for 1.5h to obtain crude scandium oxide.

[0040]Slurry the crude scandium oxide with water to obtain a slurry, add hydrochloric acid to the slurry to adjust the pH to 2.0, maintain the pH at 2.0 and react for 4 hours, filter to obtain the first filter residue, wash the first filter residue with pure water to obtain a leaching residue.

[0041] Put the first-stage leaching residue into a hydrochloric acid solution with a hydrogen ion concentration of 8 mol / L, react at 90°C for 3 hours, and filter to obtain a scandium-rich second-stage leaching solution.

[0042] The second-stage leachate is extracted and phase-separated with extractant P350 to obtain a scandium-rich organic phase; the volume concentration of the extractant P350 is 30%, and the second-stage leachate is extracted with extractant P350 and the diluent used for phase separation is sulfur kerosene. The extraction ratio is O / A=2:1, and the numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com