Nickel/zinc-manganese dioxide electrode and application thereof in wastewater treatment

A manganese dioxide electrode and electrode technology, applied in water/sewage treatment, water/sludge/sewage treatment, sterilization/microdynamics water/sewage treatment, etc., can solve the problem of tail water not meeting indirect discharge standards and environmental pollution and other problems, to achieve the effect of long service life, good adhesion and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

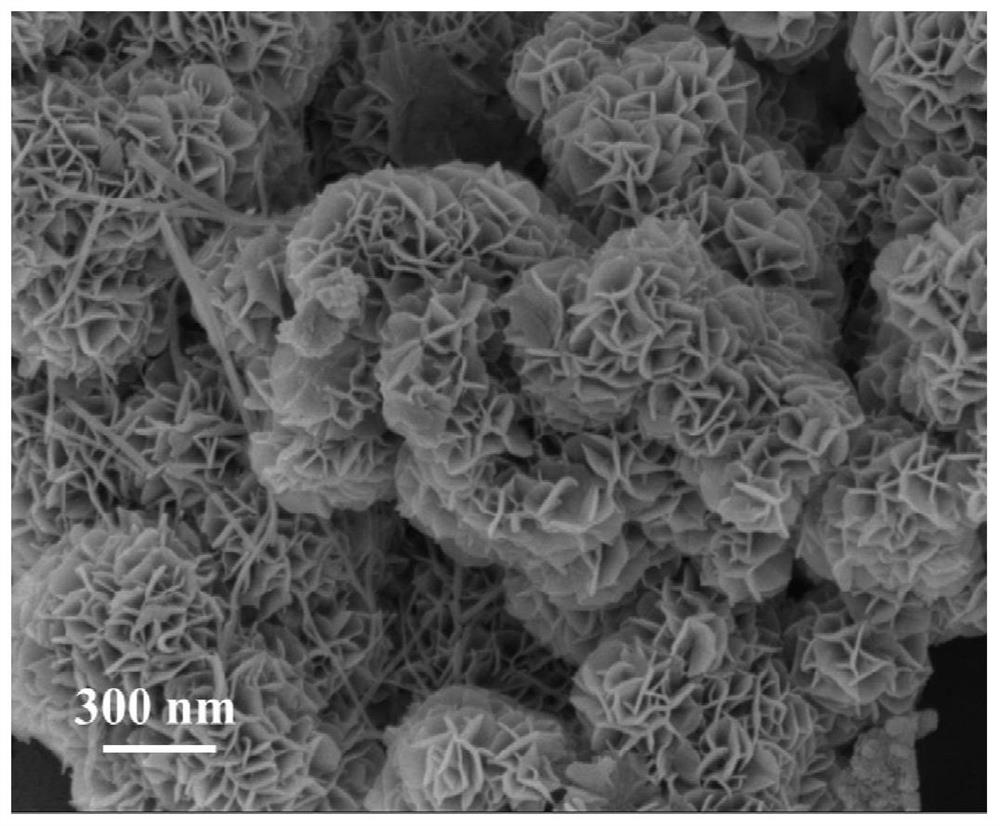

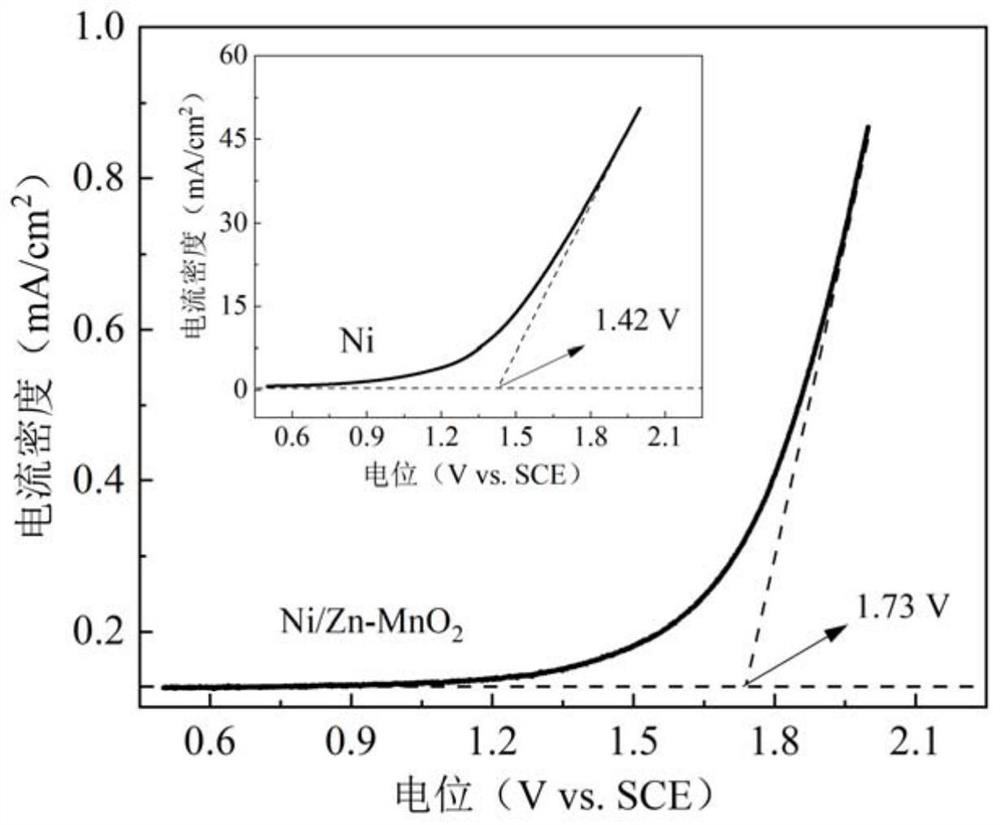

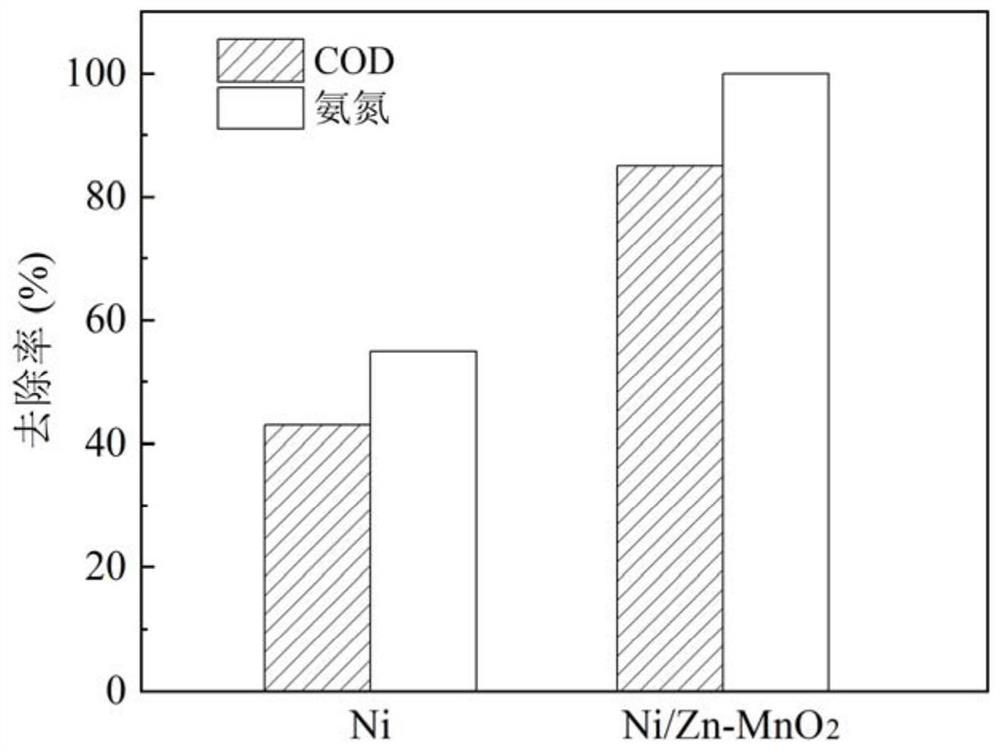

Image

Examples

Embodiment 1

[0023] (1) Separation of battery powder:

[0024] (1.1) Take the "Super brand" waste zinc-manganese dry battery and disassemble it, separate the sealing ring, plastic film and paper scraps from the black paste, and dry the remaining solid at 80°C to obtain a black powder;

[0025] (1.2) Grind the black powder obtained in step 1.1, and sieve with a 200-mesh sieve;

[0026] (1.3) Sonicate the sieved powder in ultrapure water for 30 minutes, and centrifuge to wash away the residual NH in the powder 4 Cl and other impurities, and dried at 60°C to obtain a black powder containing zinc and manganese oxides; the centrifugation speed is 6000r / min, and the centrifugation time is 10min.

[0027] (2) Preparation of electrodes

[0028] (2.1) Place the nickel foam substrate (2cm×2cm) in sequence in 3mol / L HCl, absolute ethanol and deionized water for 30min ultrasonic pretreatment to remove NiO and impurities on the surface. After washing with deionized water, dry at 60℃ without Dry unde...

Embodiment 2

[0033] (1) Separation of battery powder:

[0034] (1.1) Take the "Super brand" waste zinc-manganese dry battery and disassemble it, separate the sealing ring, plastic film and paper scraps from the black paste, and dry the remaining solid at 100°C to obtain a black powder;

[0035] (1.2) Grind the black powder obtained in step 1.1, and sieve with a 400-mesh sieve;

[0036] (1.3) Sonicate the sieved powder in ultrapure water for 60 minutes, and centrifuge to wash away the residual NH in the powder 4 Cl and other impurities, and dried at 80°C to obtain a black powder containing zinc and manganese oxides; the centrifugation speed is 10000r / min, and the centrifugation time is 5min.

[0037] (2) Preparation of electrodes

[0038] (2.1) Place the nickel foam substrate (2cm×2cm) in sequence in 3mol / L HCl, absolute ethanol and deionized water for 30min ultrasonic pretreatment to remove NiO and impurities on the surface. After washing with deionized water, dry at 80°C Dry under oxygen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com