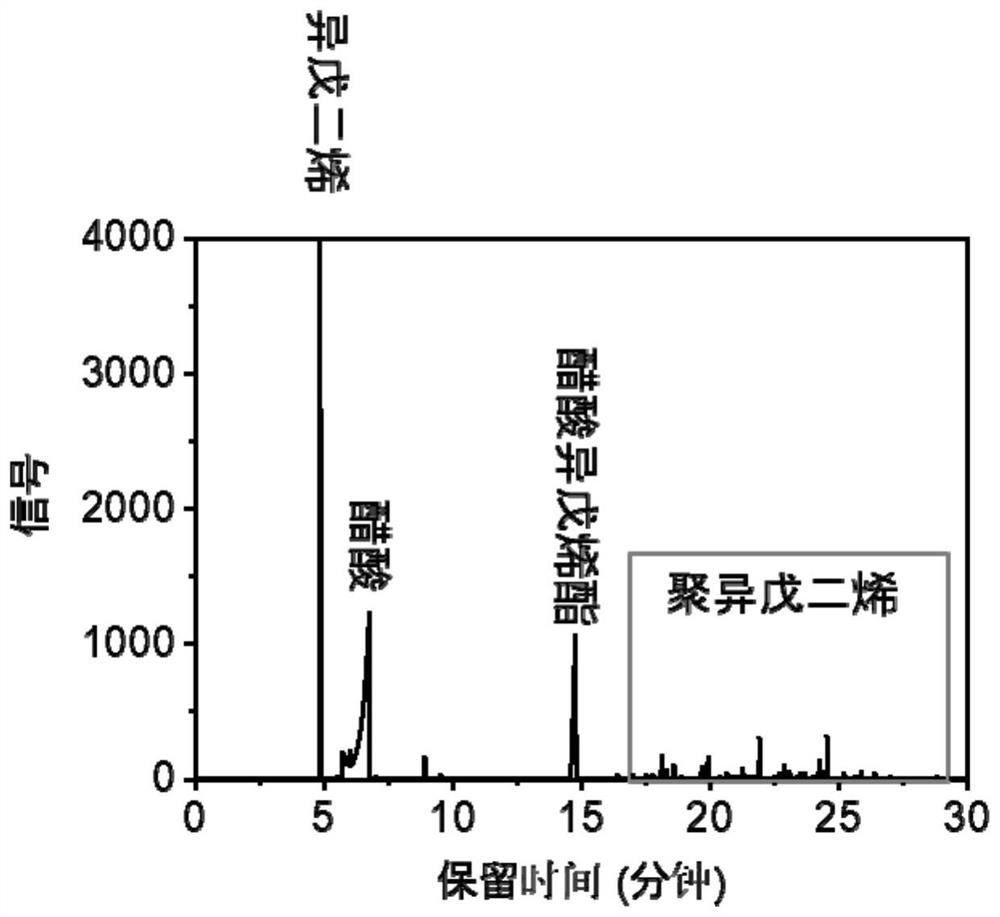

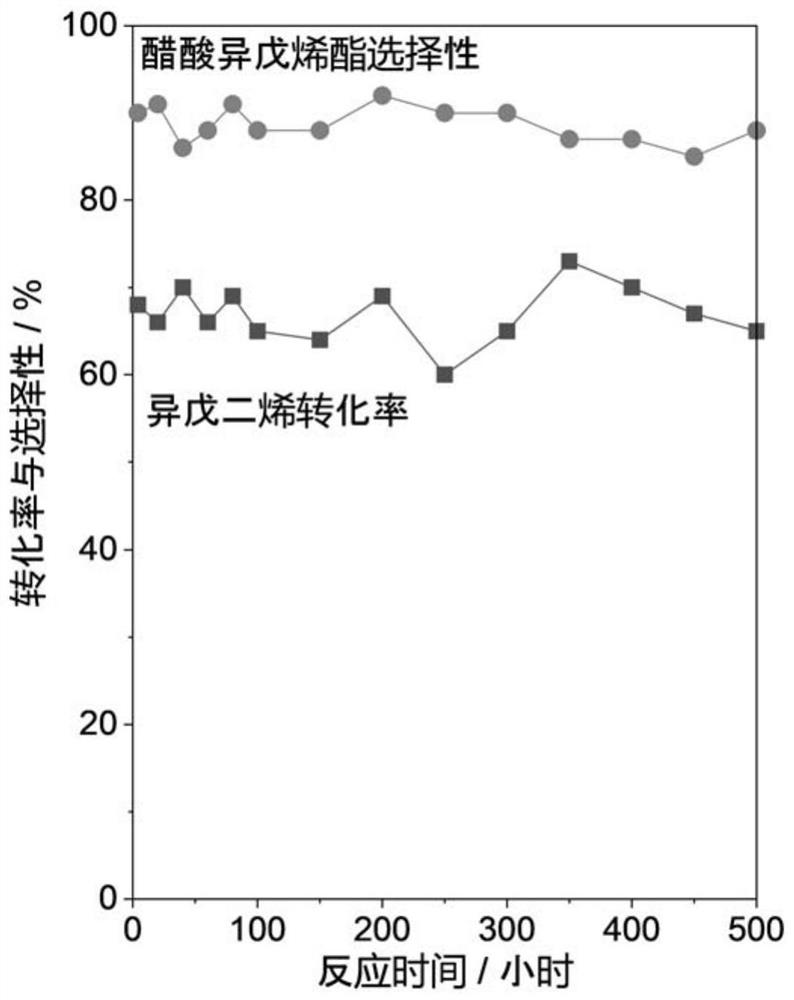

Method for preparing isopentene acetate by taking acetic acid and isoprene as raw materials

A technology of isopentenyl acetate and isoprene, which is applied in the field of compound preparation, can solve problems such as difficult product separation, easy loss of metal active components, poor stability, etc., to achieve reduced polymerization reactions and good product selectivity , reducing the effect of selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Sulfonic acid group strongly acidic resin solid acid catalyst adopts D005-II resin (Dandong Mingzhu Special Resin Co., Ltd.). Before use, soak in 10 times the volume of deionized water for 24 hours at room temperature, filter the water, add 10 times the volume of deionized water and soak for 1 hour, repeat the treatment 3 times, and then use 10 times the volume of absolute ethanol Soak for 1 hour, repeat the treatment 3 times, and finally dry at 80°C for 10 hours under a nitrogen atmosphere.

[0024] Take 0.5g of the dried catalyst and put it into a 25ml slurry bed reactor, add 1ml of isoprene and 20ml of acetic acid respectively, add a Teflon stirrer, seal it and react at 40°C, normal pressure and 1000rpm stirring speed for 4h .

Embodiment 2

[0026] The amount of acetic acid added is 10ml. Other conditions are identical with embodiment 1.

Embodiment 3

[0028] The amount of acetic acid added is 2.5ml. Other conditions are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com