Sodium alginate-phosphorus phthalocyanine photosensitizer and photocatalytic composite material, and preparation methods and application thereof

A technology of sodium alginate and composite material, applied in the field of photocatalytic materials, can solve the problems of ineffective adsorption of lead and mercury, low photosensitization efficiency, poor stable state, etc., and achieves improved photosensitization efficiency, simple synthesis route and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 sodium alginate-phosphorus phthalocyanine photosensitizer and preparation method thereof

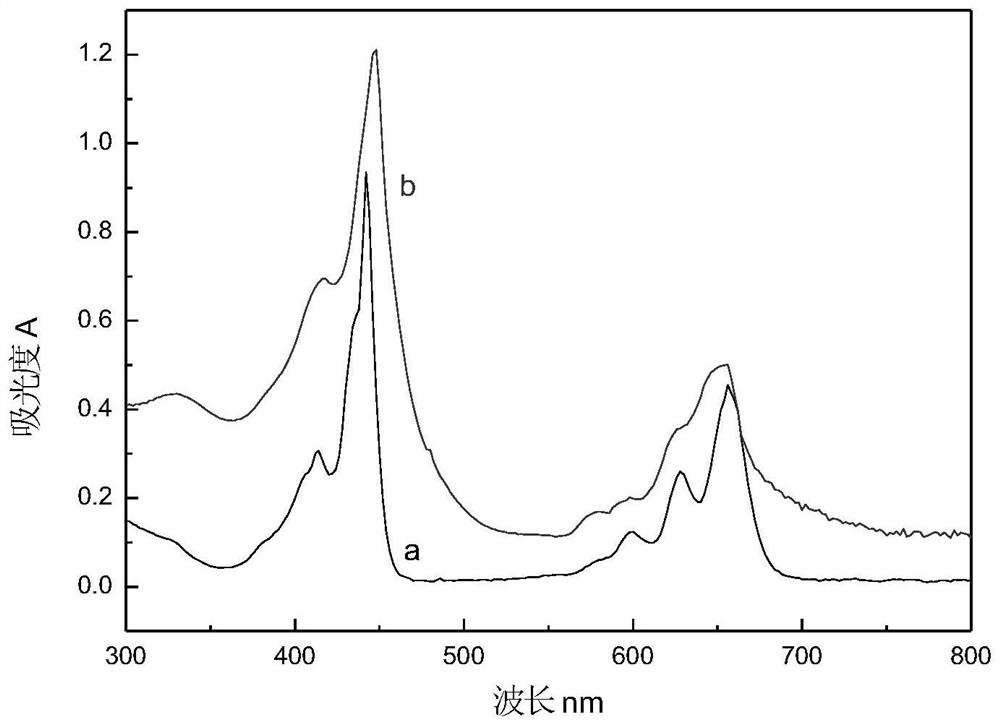

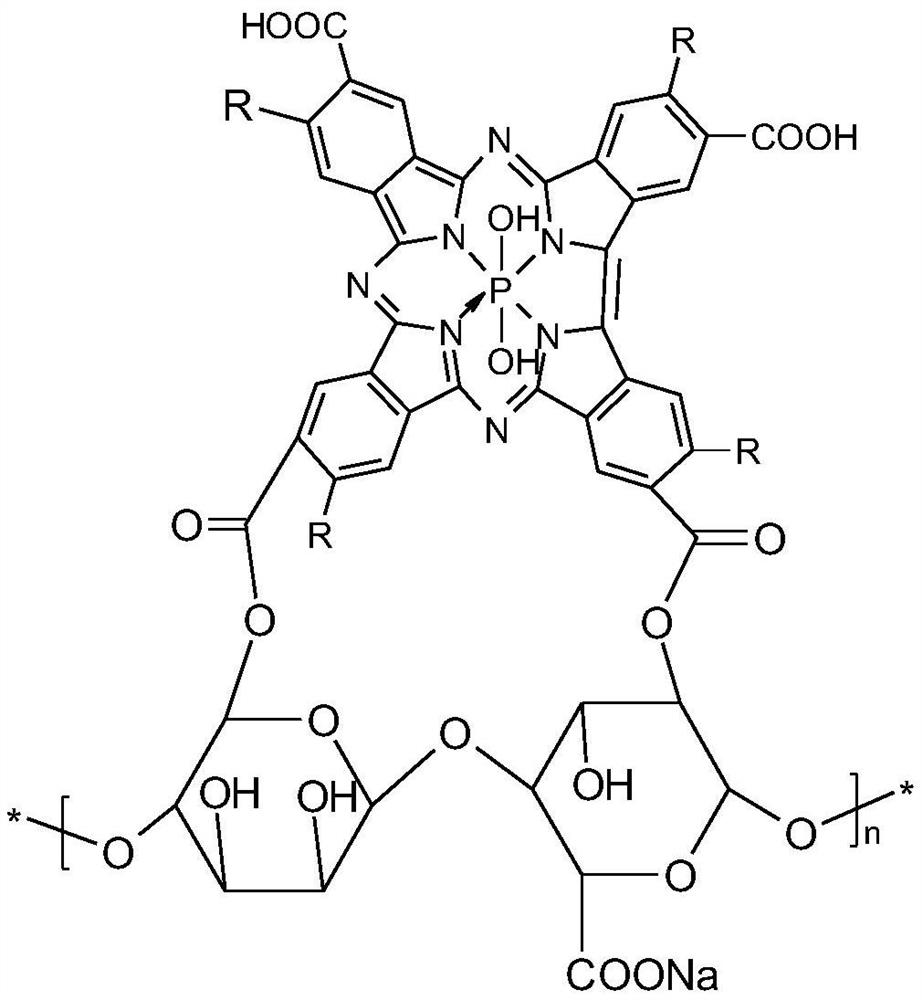

[0025] Sodium alginate-type phthalocyanine photosensitizer, the photosensitizer is a sodium alginate-phosphorus phthalocyanine binary molecular photosensitizer linked by chemical bond ester groups between phosphorus phthalocyanine and sodium alginate; the binary molecule photosensitizer The structural formula is as follows:

[0026]

[0027] Wherein, R is COOH or H, and the degree of polymerization n=100-10000.

[0028] The preparation method of the sodium alginate-phosphorus phthalocyanine binary molecular photosensitizer is as follows:

[0029] Trimellitic anhydride, metal lithium strips are melted and reacted in urea (the molar ratio of the three is 2:1:20) for 4h, adding mole fraction is 0.1% ammonium molybdate as a catalyst, reactant is dissolved in 15% NaOH after reaction cooling, Release excess ammonia, then filter, the filtrate is acidified to pH1 with HC...

Embodiment 2

[0030] The preparation method of embodiment 2 sodium alginate-phosphorus phthalocyanine photosensitizer

[0031]Trimellitic anhydride, metal lithium strips are melted and reacted in urea (the molar ratio of the three is 2.5:1:20) for 6h, adding mole fraction is 0.5% ammonium molybdate as a catalyst, reactant is dissolved in 15% NaOH after cooling, Release excess ammonia, then filter, the filtrate is acidified to pH1 with HCl, stir 2h, separate out tetracarboxy metal-free phthalocyanine, the reaction yield is about 85%; Tetracarboxy metal-free phthalocyanine and phosphorus tribromide (both moles Ratio 1:1.2) Reflux in pyridine solvent for 8h. After the reaction is over, use lye to destroy excess phosphorus tribromide and dissolve carboxylphosphorus phthalocyanine. After filtering, acidify the filtrate to pH1 with HCl to make tetracarboxyphosphorus Phthalocyanines are precipitated, and the reaction yield is about 70%; sodium alginate (G / M ratio 1:3, molecular weight 20KDa) and 0...

Embodiment 3

[0032] The preparation method of embodiment 3 sodium alginate-phosphorus phthalocyanine photosensitizer

[0033] Pyromellitic acid, metal lithium strips were melted and reacted in urea (the molar ratio of the three: 3:1:20) for 8 hours, and ammonium molybdate with a mole fraction of 1% was added as a catalyst. After the reaction was cooled, the reactant was dissolved in 15% In NaOH, release excess ammonia, then filter, acidify the filtrate to pH1 with HCl, stir for 2h, and precipitate octacarboxy metal-free phthalocyanine, the reaction yield is about 70%; octacarboxy metal-free phthalocyanine and phosphorus tribromide (The molar ratio of the two is 1:1.5) Reflux in pyridine solvent for 10h. After the reaction, use lye to destroy excess phosphorus tribromide and dissolve carboxylphosphorus phthalocyanine. After filtering, acidify the filtrate to pH1 with HCl , so that octacarboxyphosphorus phthalocyanine is precipitated, and the reaction yield is about 60%; sodium alginate (G / M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com