Device and method for efficiently degrading bisphenol A by coupling illumination with electroactive biological membrane

An active biofilm, coupled electricity technology, applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc., to achieve the effects of low energy consumption, simple operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The domestication of embodiment 1 electroactive biofilm

[0037] Before domesticating the electrochemical biofilm, it is necessary to configure the growth medium to grow the electrochemical biofilm on the graphite electrode.

[0038] Growth medium: disodium hydrogen phosphate (Na 2 HPO 4 12H 2 O) 11.4g, sodium dihydrogen phosphate (NaH 2 PO 4 2H 2 O) 2.78g, potassium chloride (KCl) 0.13g, ammonium chloride (NH 4 Cl) 0.31g, sodium acetate (CH 3 COONa) 1g, vitamin mixed nutrient solution 10ml, mineral solution 10ml, dissolved in dd H 2 O and set the volume to 1L.

[0039] Among them, the formula of vitamin mixed nutrient solution is shown in Table 1, and all substances in the formula are dissolved in dd H 2 Dilute to 1L after O and store at 4°C.

[0040] Table 1 vitamin mixed nutrient solution

[0041]

[0042]

[0043] The formula of the mineral solution is shown in Table 2. All the substances were dissolved in water and the volume was adjusted to 1 L, a...

Embodiment 2

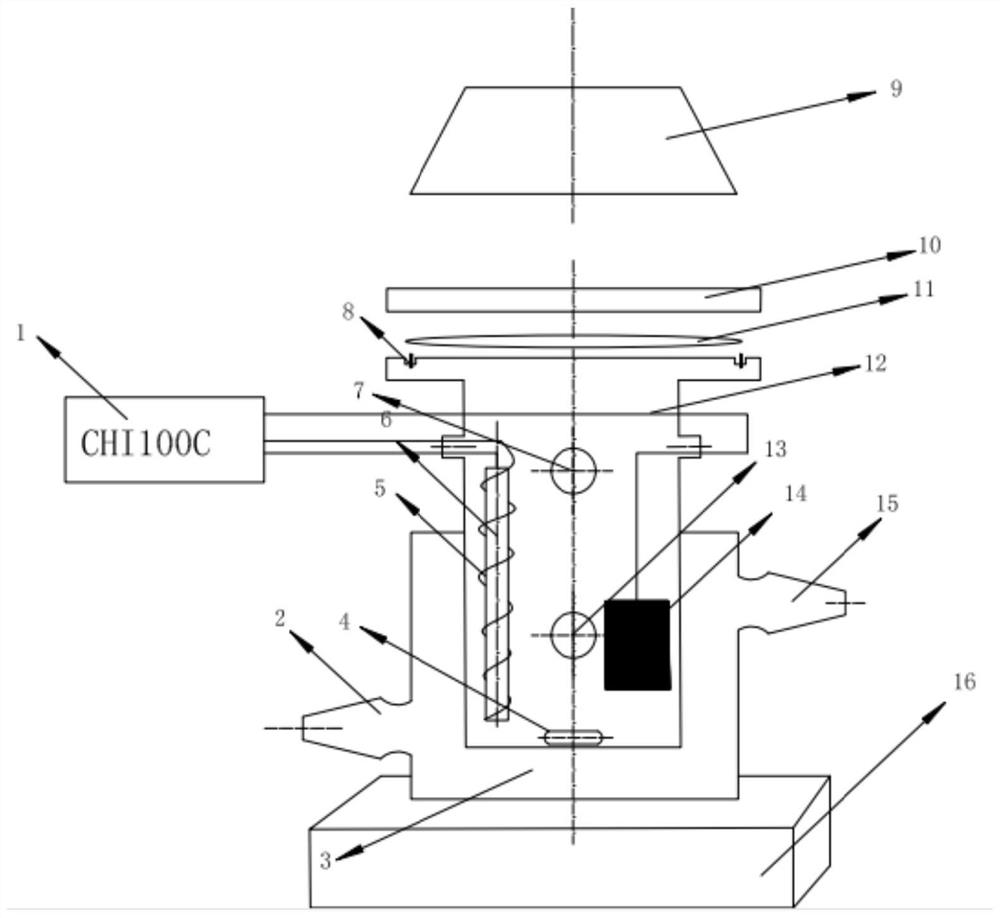

[0047] Example 2 Construction of a device for degrading bisphenol A by light coupling electroactive biofilm

[0048] The device for degrading bisphenol A by light coupling electroactive biofilm of the present invention is as follows: figure 1 As shown, it includes a reactor 12 , an electrochemical workstation 1 and a xenon lamp 9 . The reactor 12 is a barrel-shaped structure with an upper opening, equipped with a transparent glass cover 10 that is detachably connected to the upper opening, and a rubber ring 11 is provided under the transparent glass cover 10, and a top groove 8 is provided on the top of the reactor. The transparent glass cover 10 is pressed with a glass clamp, and the rubber ring 11 is pressed into the top groove 8 to ensure the sealing effect of the reactor. The reactor 12 is provided with the graphite plate anode 14 of the domesticated electroactive biofilm, the titanium wire cathode 5 and the Ag / AgCl reference electrode 6, and the electrode of the electroc...

Embodiment 3

[0050] The treatment of embodiment 3 bisphenol A waste water

[0051] After the light-coupled electroactive biofilm degradation device for bisphenol A is correctly connected, pour 100mL of wastewater with a bisphenol A concentration of 1mg / L, completely seal it, and then aerate it for 5 minutes to make the reactor in an anaerobic state. The rotating speed of the constant temperature magnetic stirrer was set to 100rpm, and the xenon lamp illuminator above the reactor was turned on. The water inlet of the outer ring of the reactor is connected to the faucet, and the water outlet is placed on the edge of the pool. Turn on the faucet to ensure that the flowing water passes through the outer ring of the reactor evenly, so as to ensure that the reactor will not be affected by the increase in temperature due to light. Turn on the electrochemical workstation to start the treatment of bisphenol A wastewater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com