Low-temperature-resistant hydrolysis-resistant glass fiber reinforced PBT and preparation method thereof

A hydrolysis-resistant and low-temperature-resistant technology, which is applied in the field of polymer materials to achieve excellent mechanical properties, improved strength, and excellent overall flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

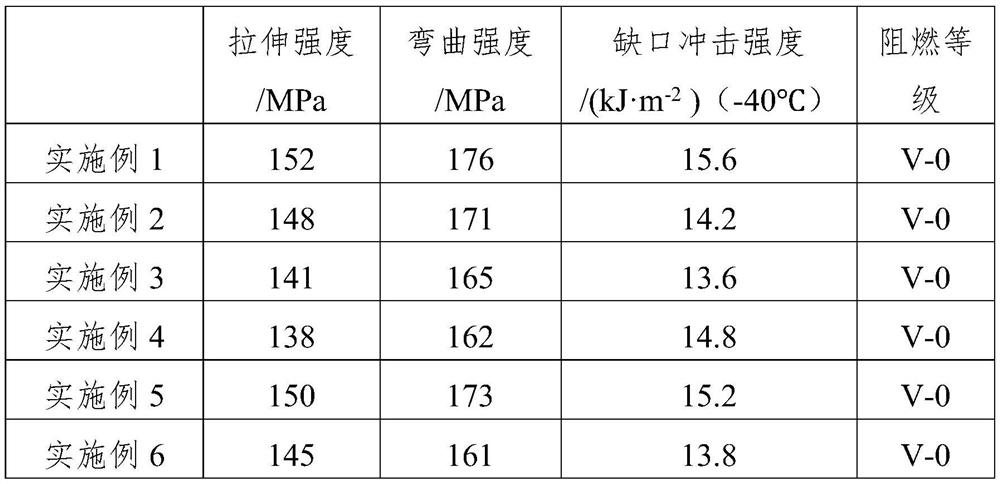

Examples

Embodiment 1

[0028] A low-temperature-resistant and hydrolysis-resistant glass fiber-reinforced PBT, comprising the following raw materials in parts by weight: 100 parts of polybutylene terephthalate PBT, 15 parts of zinc oxide modified glass fiber, 1.1 parts of iron-doped nano-titanium dioxide, nano-moisture 3 parts of soil removal, 0.4 parts of vinyltriacetoxysilane, 5.5 parts of toughening agent SWR-6B, 0.5 parts of antioxidant 1010.

[0029] The above polybutylene terephthalate PBT had a viscosity of 1.0 dL / g. The particle diameter of the iron-doped nano-titanium dioxide is 30-80nm, and the doping amount is 1.5%. The particle size of nano-montmorillonite is 20-100nm.

[0030] Zinc oxide modified glass fiber is prepared by the following method:

[0031] (1) Dissolve 1 part of zinc acetate in 50 parts of ethylene glycol, stir for 25 minutes, add 3 parts of chopped glass fiber, and then ultrasonically disperse for 50 minutes;

[0032] Chopped glass fibers have a length of 0.5-5 mm and ...

Embodiment 2

[0036] A low-temperature-resistant and hydrolysis-resistant glass fiber-reinforced PBT, comprising the following raw materials in parts by weight: 100 parts of polybutylene terephthalate PBT, 16 parts of zinc oxide modified glass fiber, 0.8 parts of iron-doped nano-titanium dioxide, and nano-moisture 5 parts of soil removal, 0.5 parts of vinyltriacetoxysilane, 3 parts of toughening agent SWR-6B, 0.5 parts of antioxidant 168.

[0037] The above polybutylene terephthalate PBT had a viscosity of 1.0 dL / g. The particle diameter of the iron-doped nano-titanium dioxide is 30-80nm, and the doping amount is 1.5%. The particle size of nano-montmorillonite is 20-100nm.

[0038] Zinc oxide modified glass fiber is prepared by the following method:

[0039] (1) Dissolve 1 part of zinc acetate in 50 parts of ethylene glycol, stir for 30 minutes, add 2-3 parts of chopped glass fiber, and then ultrasonically disperse for 30 minutes;

[0040] Chopped glass fibers have a length of 0.5-5 mm a...

Embodiment 3

[0044] A low-temperature-resistant and hydrolysis-resistant glass fiber-reinforced PBT, comprising the following raw materials in parts by weight: 100 parts of polybutylene terephthalate PBT, 12 parts of zinc oxide modified glass fiber, 0.7 parts of iron-doped nano-titanium dioxide, and nano-moisture 2 parts of soil removal, 0.5 parts of vinyltriacetoxysilane, 5 parts of toughening agent SWR-6B, 0.5 parts of antioxidant 168.

[0045] The above polybutylene terephthalate PBT had a viscosity of 1.0 dL / g. The particle size of the iron-doped nano-titanium dioxide is 30-80nm, and the doping amount is 2%. The particle size of nano-montmorillonite is 20-100nm.

[0046] The preparation method of the zinc oxide modified glass fiber is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com