Method for producing soil conditioner from iron ore tailings

A technology for soil conditioner and iron ore tailings, which is applied in the field of producing soil conditioners by using iron ore tailings, can solve the problems of limited soil improvement effect, single raw material, etc., and achieves low raw material cost, improved pH value, and saved production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] (2) Preparation of porous viscous material: take active carbon, coal cinder and limestone as raw materials, mix them uniformly in a ratio of 1:80:19 by weight, add an agricultural adhesive, and the agricultural adhesive is carboxymethyl cellulose Sodium is made by gelatinization. During specific operation, the gelatinized sodium carboxymethylcellulose is mixed with the above mixture in three batches. After each addition of sodium carboxymethylcellulose, it should be stirred evenly to obtain porous viscous thing;

[0030] (3) Carry out drying treatment to the porous sticky matter: send the porous sticky matter obtained in step (2) into an oven for baking, the oven temperature is controlled at 100° C., and the moisture content of the porous sticky matter is controlled at 15%;

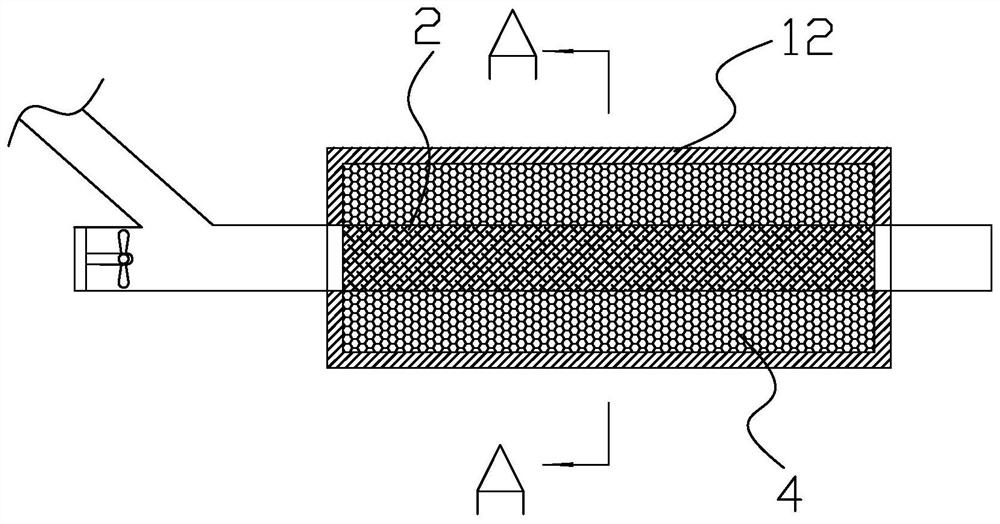

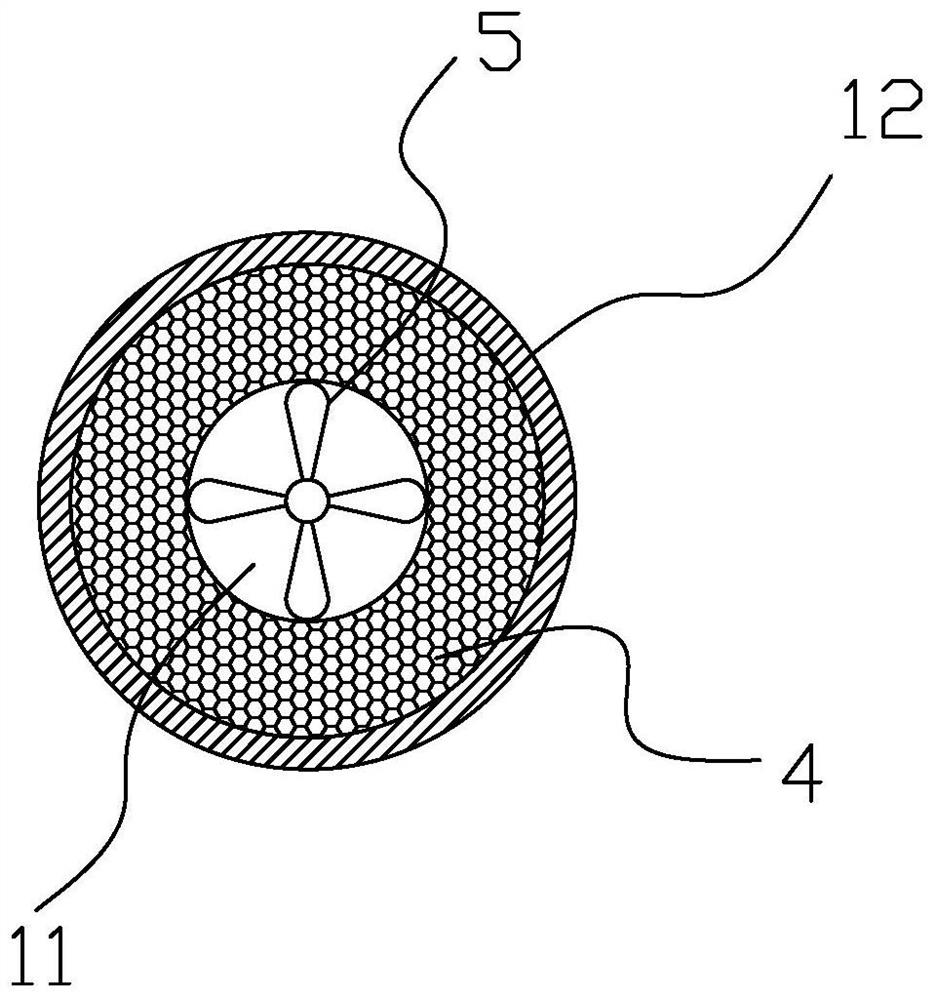

[0031] (4) Granulation: Send the porous viscous matter into a granulator for granulation. During granulation, the temperature of the granulator is controlled within 120°C, so that the pore structur...

Embodiment 2

[0035] Compared with Embodiment 1, the horizontal front end of the remixing treatment device in this embodiment is also provided with a material push rod, which is used to push and remove the porous sticky matter adhered to the tailings powder out of the storage space, so that the preparation of the soil conditioner can be sustainable. Compared with the examples, this scheme can be used to continuously prepare soil conditioners in large quantities.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com