C-SF-FA flexible conductive film based on silk fibroin, wearable wound monitoring sensor and preparation method thereof

A C-SF-FA and SF-FA technology, applied in the field of biomaterials, can solve the problems of poor air permeability, poor real-time data, poor biocompatibility, etc., and achieve good air permeability, lower production costs, and high sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

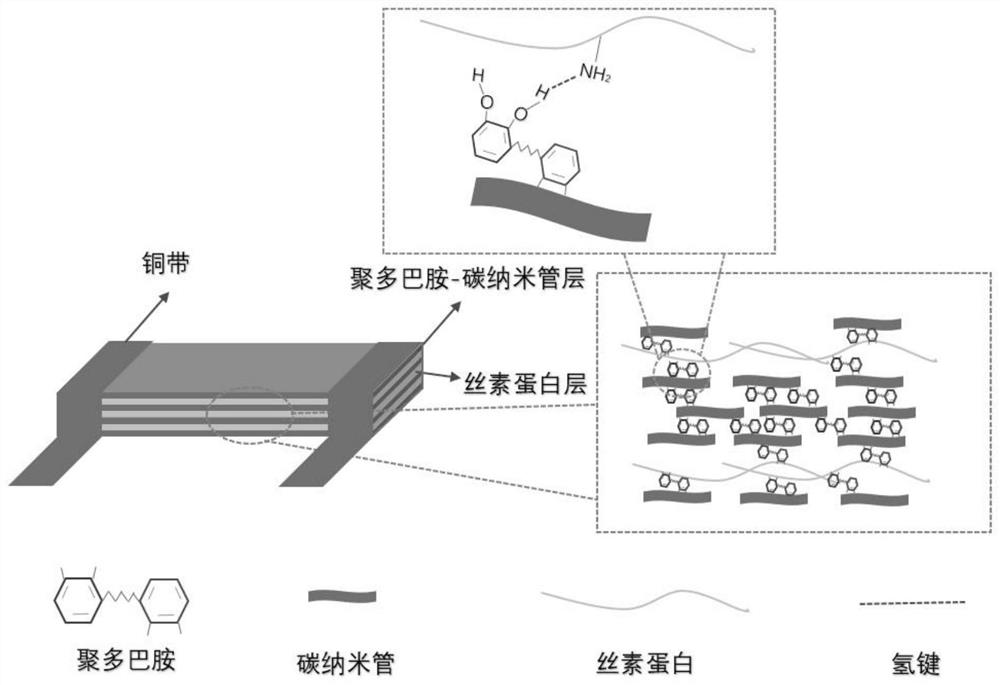

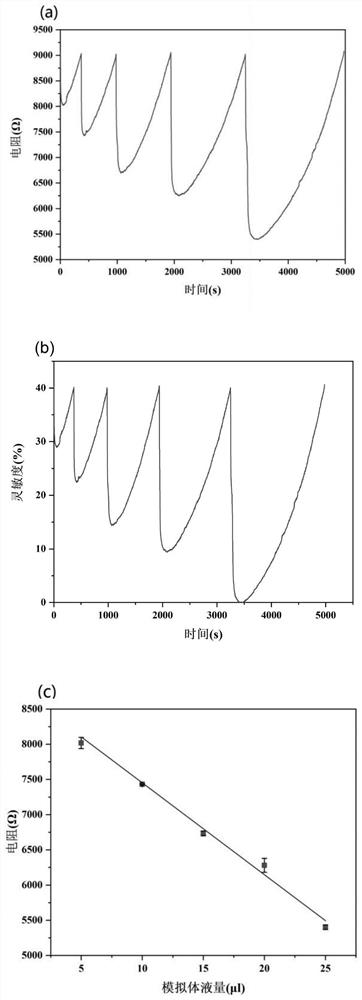

[0042]The preparation of a flexible and wearable wound monitoring sensor based on silk fibroin is performed according to the following steps:

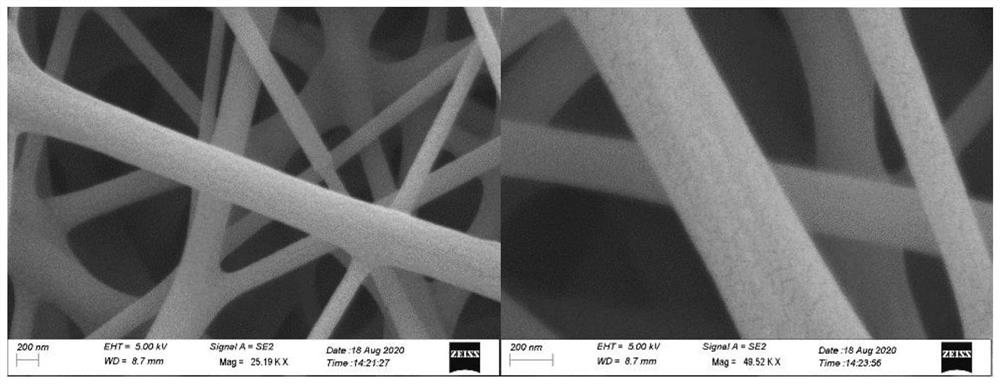

[0043] 1) Bombyx silkworm cocoons are degummed with 2mol / L sodium carbonate solution. After degumming, wash and dry naturally. 2wv%, the formic acid concentration is 98wv%) is dissolved for more than 3 hours to form a silk fibroin solution (SF solution), and then the obtained SF solution is dried at room temperature for 24 hours to obtain silk fibroin. Then the obtained dried silk fibroin was soaked in deionized water for 10 hours to remove excess calcium chloride and formic acid, and dried. Then the obtained silk fibroin was dried at 35°C and dissolved in formic acid again to obtain a SF-FA electrospinning solution with a silk fibroin (SF) content of 20wv%.

[0044] 2) Dissolving 5 mg of dopamine (DA) in 1 ml of water, adding 5 mg of carbon nanotube (CNT) and ultrasonically dispersing to obtain a DA-CNT solution.

[0045] 3) The SF-...

Embodiment 2

[0049] The preparation of a flexible and wearable wound monitoring sensor based on silk fibroin is performed according to the following steps:

[0050] 1) Bombyx silkworm cocoons are degummed by boiling with 2mol / L sodium carbonate solution, washed and air-dried naturally after degumming is completed, and dissolved in lithium bromide / formic acid (FA) dissolution system after air-drying (wherein, the concentration of lithium bromide is 10wv%, the concentration of formic acid 98wv%) was dissolved for more than 3 hours to form a silk fibroin solution (SF solution), and then the obtained SF solution was dried at room temperature for 12 hours to obtain silk fibroin. Then the obtained dried silk fibroin was soaked in deionized water for 10 hours to remove excess lithium bromide and formic acid, and dried. Then the obtained silk fibroin was dried at 50° C. and dissolved in formic acid again to obtain a SF-FA electrospinning solution with a silk fibroin (SF) content of 20wv%.

[0051...

Embodiment 3

[0056] The preparation of a flexible and wearable wound monitoring sensor based on silk fibroin is performed according to the following steps:

[0057] 1) Bombyx silkworm cocoons are degummed with 2mol / L sodium carbonate solution. After degumming, wash and dry naturally. 5wv%, the formic acid concentration is 98wv%) is dissolved for more than 3 hours to form a silk fibroin solution (SF solution), and then the obtained SF solution is dried at room temperature for 24 hours to obtain silk fibroin. Then the obtained dried silk fibroin was soaked in deionized water for 10 hours to remove excess calcium chloride and formic acid, and dried. Then the obtained silk fibroin was dried at 45°C and dissolved in formic acid again to obtain a SF-FA electrospinning solution with a silk fibroin (SF) content of 20wv%.

[0058] 2) Dissolving 20 mg of dopamine (DA) in 1 ml of water, adding 10 mg of carbon nanotube (CNT) and ultrasonically dispersing to obtain a DA-CNT solution.

[0059] 3) The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com