Rhodium-based catalyst for glycollic aldehyde synthesis and preparation method thereof

A catalyst and glycolaldehyde technology, applied in the direction of catalyst activation/preparation, carbon monoxide reaction preparation, molecular sieve catalyst, etc., can solve the problems of difficult catalyst separation, low conversion rate of formaldehyde, influence of Rh activity, etc., and achieve easy recovery and low conversion rate , the effect of increasing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

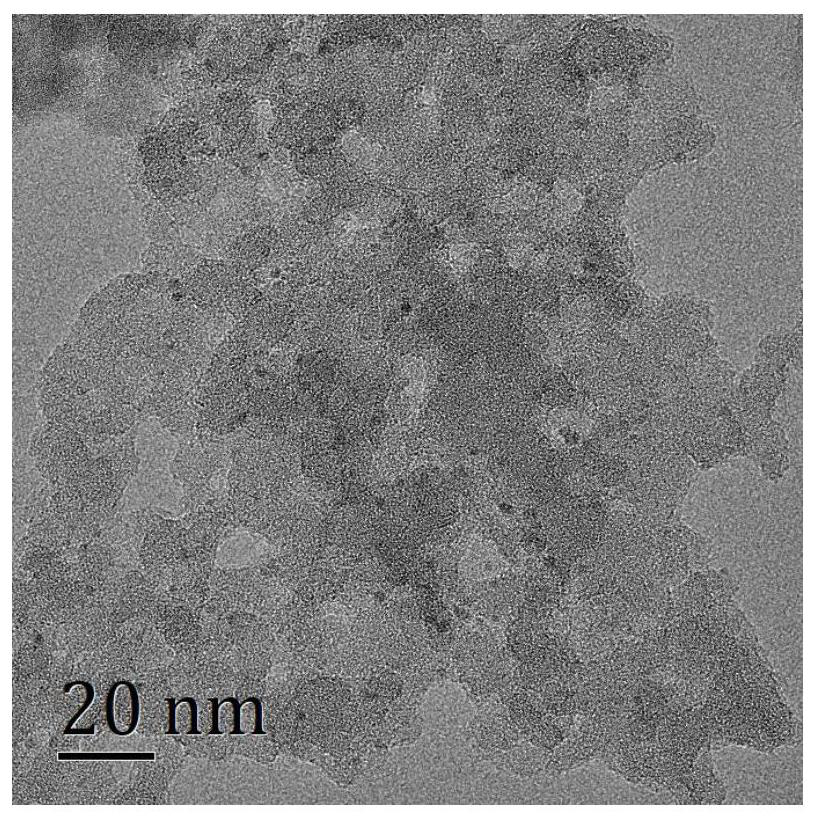

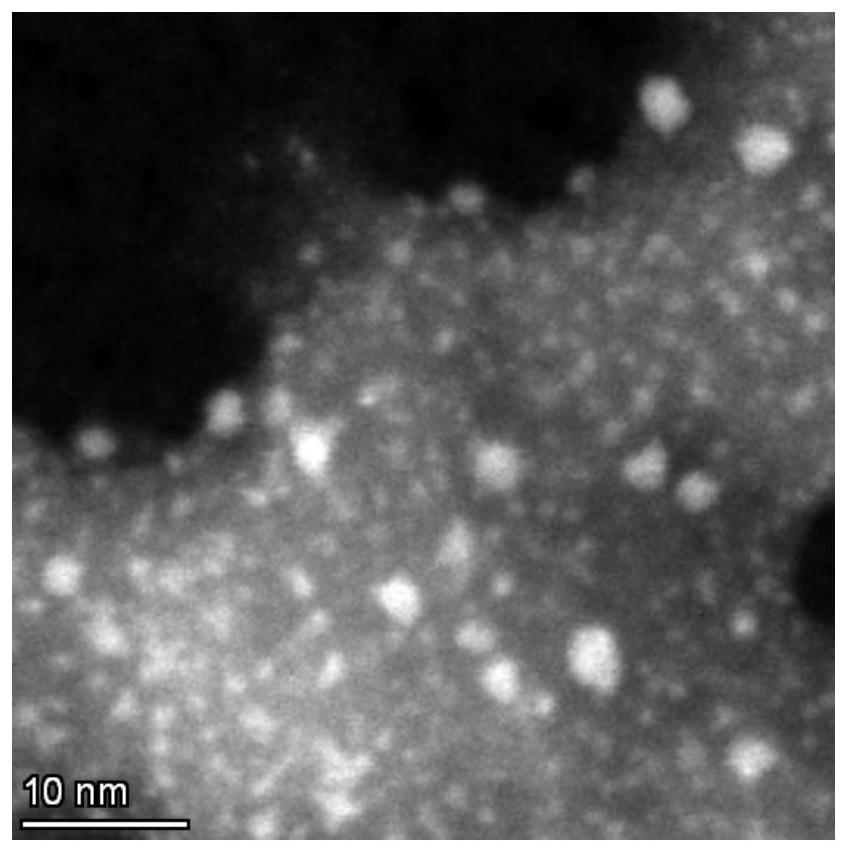

[0024] A. Accurately weigh 1.5g SiO 2 , placed in a 250ml three-necked flask, added 50mL of toluene, and continuously fed dry N 2 , stirred magnetically at room temperature for 30 minutes, added 2 mL of 3-aminopropyltriethoxysilane dropwise to a constant pressure funnel, raised the temperature to 110°C, stirred for 24 hours, filtered and washed, and vacuum-dried at 50°C for 12 hours to obtain amino-modified N -SiO 2 .

[0025] B. In a 250mL three-necked flask, 0.1g rhodium precursor Rh(acac)(CO) 2 Dissolve in 60ml of ethanol solution, stir magnetically for 30min, and prepare 6.4mmol / L rhodium solution.

[0026] C. Take the carrier N-SiO obtained in step A 2 1.0g is added in the rhodium solution of step B, continuously feeds dry N 2 Stir at room temperature for 16 hours, impregnate and load, filter and wash to remove excess ethanol and unsupported Rh, and dry the catalyst precursor at 90°C for 3 hours to obtain Rh / N-SiO 2 In the catalyst, the mass percentage of N is abou...

Embodiment 2

[0029] A: Accurately weigh 3.0g of NaY molecular sieve, place it in a 250ml three-necked flask, add 1000mL of toluene, and continuously feed dry N 2 , stirred magnetically at room temperature for 50 minutes, added 4 mL of 3-aminopropyltriethoxysilane dropwise to a constant pressure funnel, raised the temperature to 50°C, stirred for 24 hours, filtered and washed, and dried in vacuum at 80°C for 12 hours.

[0030] B: In a 250mL three-necked flask, the rhodium precursor Rh(acac)(CO) 20.05g was dissolved in 40mL of absolute ethanol, magnetically stirred for 60min, and configured as a 4.8mmol / L rhodium solution.

[0031] C. Take 1.0 g of the carrier N-NaY obtained in step A and add it to the rhodium solution in step B, and continue to feed dry N-NaY 2 Stir at room temperature for 16 hours, impregnate and load, filter and wash to remove excess ethanol and unsupported Rh, and dry the catalyst precursor at 90°C for 3 hours to obtain the supported catalyst Rh / N-NaY, wherein the mass ...

Embodiment 3

[0034] A. Accurately weigh 1.5g SiO 2 , placed in a 250ml three-necked flask, added 50mL of toluene, and continuously fed dry N 2 , stirred magnetically at room temperature for 30 minutes, added 2 mL of γ-aminoethylaminopropyltrimethoxysilane dropwise to a constant-pressure funnel, raised the temperature to 110°C, stirred for 48 hours, filtered and washed, and vacuum-dried at 50°C for 12 hours to obtain amino-modified N-SiO 2 ; Wherein the mass percentage of N is 4.22%, and the mass percentage of Rh is 3.03%;

[0035] B. In a 250mL three-necked flask, 0.1g rhodium precursor Rh(acac)(CO) 2 Dissolve in 60ml of ethanol solution, stir magnetically for 30min, and prepare 6.4mmol / L rhodium solution.

[0036] C. Take 1.0 g of the carrier N-NaY obtained in step A and add it to the rhodium solution in step B, and continue to feed dry N-NaY 2 Stirring at room temperature for 28 hours to impregnate and load, filter and wash to remove excess ethanol and unloaded Rh, and dry the cataly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com