Preparation method of brominated perfluoroalkane

The technology of iodo perfluoroalkane and perfluoroalkane is applied in the field of production of fluorine-containing fine chemicals, can solve the problems of incapable of continuous industrialized production, high reaction temperature, and high equipment requirements, and achieves high production efficiency, safe equipment operation, and low cost. The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

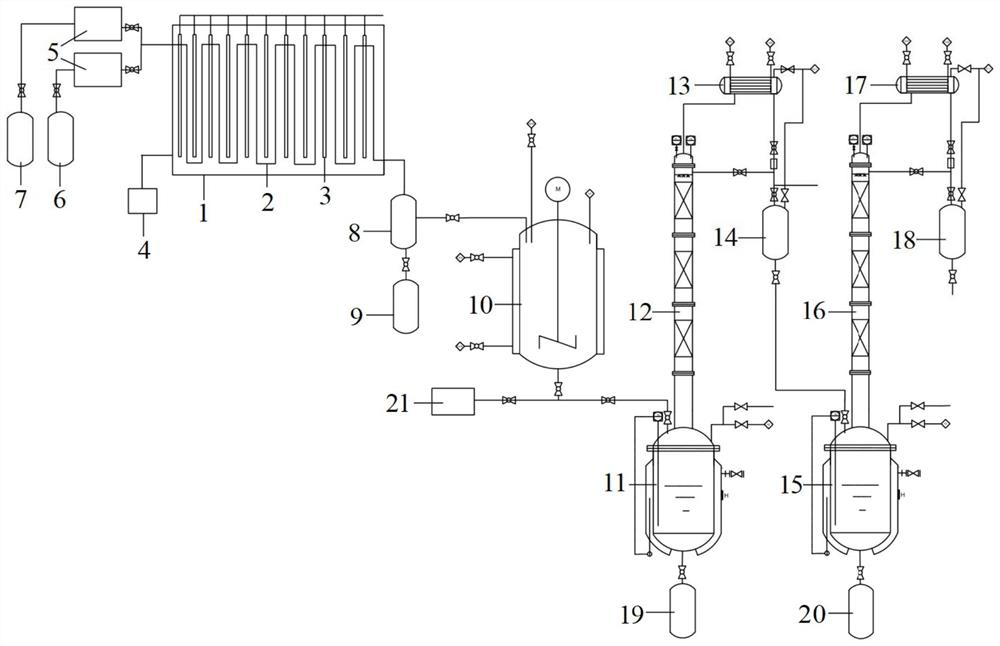

Method used

Image

Examples

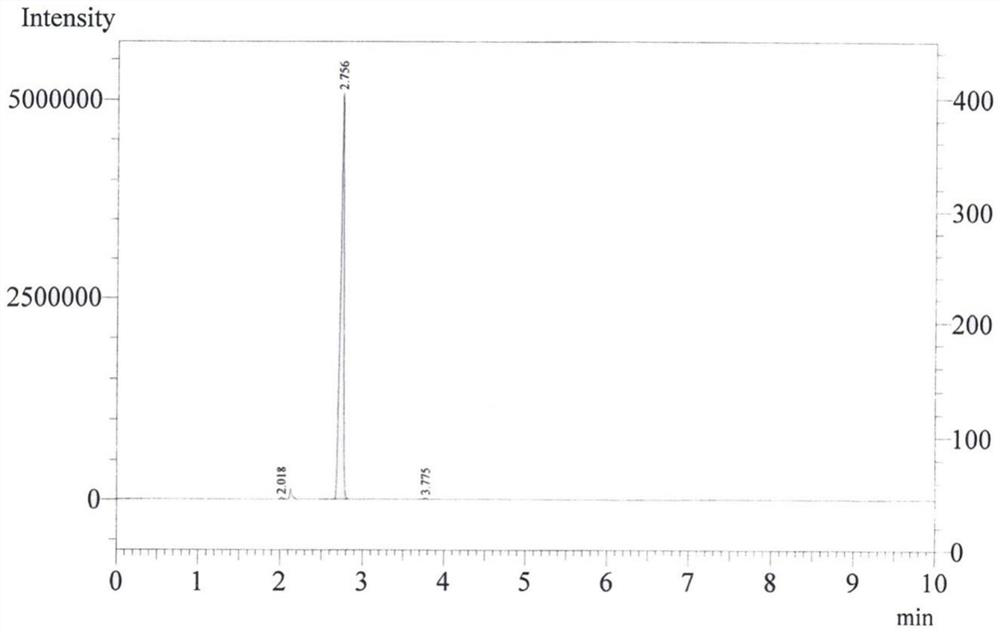

Embodiment 1

[0047] A preparation method of brominated perfluorooctane, the specific steps are as follows:

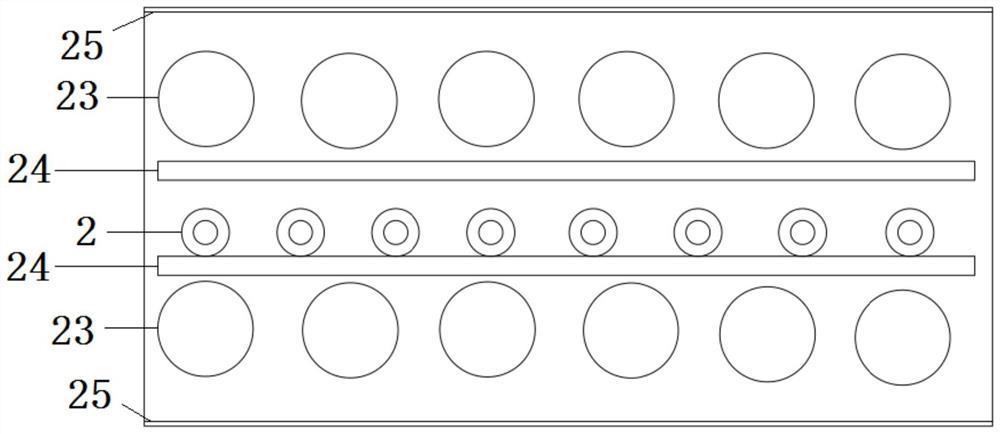

[0048] (1) Heat the quartz reaction tube to keep the temperature in the tube between 70°C, turn on the light source of the photochemical reactor, and set the wavelength to 254nm;

[0049] (2) Turn on the sampling pump, adjust the flow rate of perfluoroiodooctane to 5mL / min, and the flow rate of bromine to 1.5mL / min, and enter the photochemical reactor for continuous reaction;

[0050] (3) The reaction mixture flows into the phase separation tank for preliminary separation, bromine and the iodine bromide generated are layered with the product, and the lower layer is the bromine and iodine bromide layer. After every 36 hours, the bromine is released once in the recovery tank , while releasing the crude product of the target product in the upper layer to flow into the washing tank;

[0051] (4) the crude product of the target product flowing into the washing tank is treated with 30% s...

Embodiment 2

[0058] A preparation method of brominated perfluorohexane, the specific steps are as follows:

[0059] (1) Heat the quartz reaction tube to keep the temperature in the tube between 60°C, turn on the light source of the photochemical reactor, and set the wavelength to 254nm;

[0060] (2) Turn on the injection pump, adjust the flow rate of perfluoroiodohexane to 5mL / min, and the flow rate of bromine to 1.5mL / min, and enter the photochemical reactor for continuous reaction;

[0061] (3) The reaction mixture flows into the phase separation tank for preliminary separation, bromine and the iodine bromide generated are layered with the product, and the lower layer is the bromine and iodine bromide layer. After every 36 hours, the bromine is released once in the recovery tank , while releasing the crude product of the target product in the upper layer to flow into the washing tank;

[0062] (4) the crude product of the target product flowing into the washing tank is treated with 30% ...

Embodiment 3

[0070] A preparation method of bromoperfluorodecane, the specific steps are as follows:

[0071] (1) Heat the quartz reaction tube to keep the temperature in the tube between 70°C, turn on the light source of the photochemical reactor, and set the wavelength to 254nm;

[0072] (2) Turn on the injection pump, adjust the flow rate of perfluoroiododecane to 5mL / min, and the flow rate of bromine to 1.5mL / min, and enter the photochemical reactor for continuous reaction;

[0073] (3) The reaction mixture flows into the phase separation tank for preliminary separation, bromine and the iodine bromide generated are layered with the product, and the lower layer is the bromine and iodine bromide layer. After every 36 hours, the bromine is released once in the recovery tank , while releasing the crude product of the target product in the upper layer to flow into the washing tank;

[0074] (4) the crude product of the target product flowing into the washing tank is treated with 30% sodium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com