Synthesis method of ceramic ink solvent

A technology of ceramic ink and synthesis method, which is applied in chemical instruments and methods, ink, preparation of organic compounds, etc., can solve the problems of uncontrollable morphology, low catalytic activity, small specific surface area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of synthetic method of ceramic ink solvent of the present embodiment is as follows:

[0040] (1) Preparation of sea urchin-like AlOOH: First, 1 mmol of aluminum sulfate and 4 mmol of urea were ultrasonically treated, then completely dissolved in a solvent composed of 100 mL of deionized water and 50 mL of absolute ethanol to obtain a mixed solution A, and then to the mixed solution A Add 2mL of oleic acid surfactant to the mixture and stir to obtain a mixed solution B, then put the mixed solution B into a 150mL reaction kettle, place the reaction kettle in an oven at 180°C for a high temperature reaction for 4h, obtain the product, and cool the product to At room temperature, after alternately washing and filtering with absolute ethanol and deionized water, put it into an oven at 60°C for 4 hours to obtain sea urchin-like AlOOH.

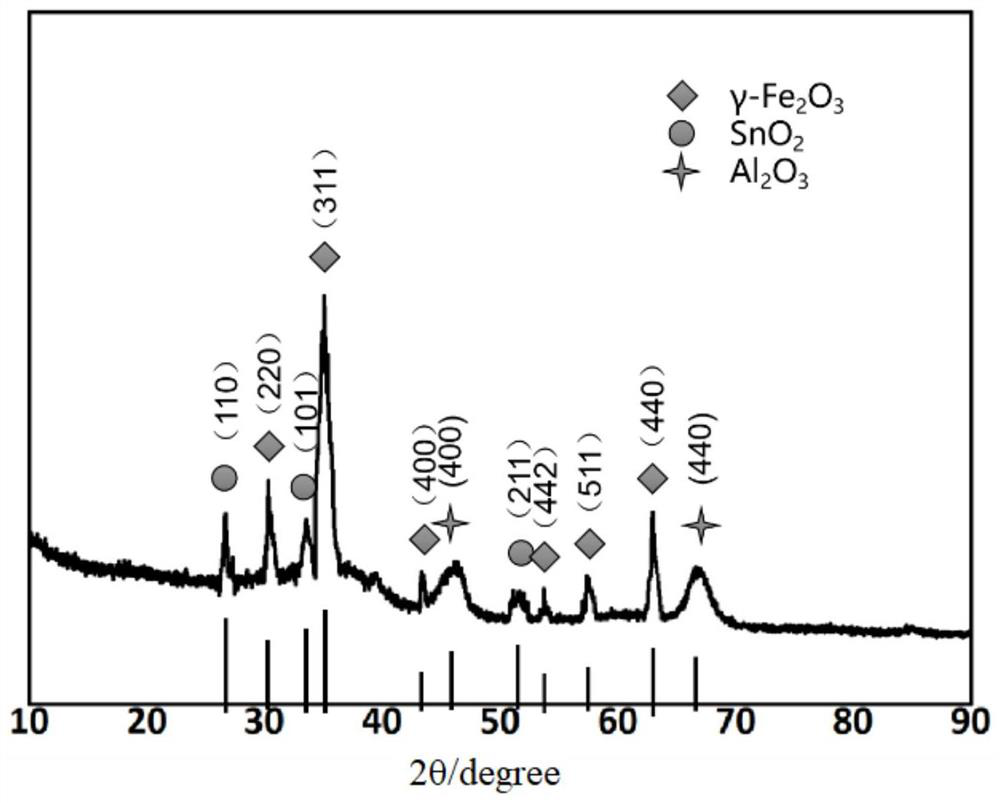

[0041] (2) Composite material SnO 2 / Fe 2 o 3 / Al 2 o 3 Preparation: 0.5 g of sea urchin-like AlOOH powder was dispersed in a mix...

Embodiment 2

[0045]The synthesis method of a kind of ceramic ink solvent of the present embodiment is basically the same as that of embodiment 1, and its difference is: the present embodiment adds the Fe(NO of 1:0.1 mass ratio in step (3). 3 ) 3 9H 2 O and SnCl 4 ·5H 2 O(where Fe(NO 3 ) 3 9H 2 The quality of O remains constant at 0.5g), the resulting solid acid catalyst SO 4 2- / SnO 2 / Fe 2 o 3 / Al 2 o 3 Labeled as 0.6-SSFeAl(1:0.1).

[0046] Then use solid acid catalyst 0.6-SSFeAl (1:0.1) to synthesize isooctyl palmitate.

Embodiment 3

[0048] The synthesis method of a kind of ceramic ink solvent of the present embodiment is basically the same as that of embodiment 1, and its difference is: the present embodiment adds the Fe(NO of 1:0.15 in mass ratio) in step (3). 3 ) 3 9H 2 O and SnCl 4 ·5H 2 O(where Fe(NO 3 ) 3 9H 2 The quality of O remains constant at 0.5g), the resulting solid acid catalyst SO 4 2- / SnO 2 / Fe 2 o 3 / Al 2 o 3 Labeled as 0.6-SSFeAl (1:0.15).

[0049] Then use solid acid catalyst 0.6-SSFeAl (1:0.15) to synthesize isooctyl palmitate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com