Preparation method of water-based orange peel epoxy curing agent and flat coating agent matched with waterborne orange peel epoxy curing agent

An epoxy curing agent and orange pattern technology, applied in the direction of epoxy resin coatings, coatings, etc., can solve the problems of coating water resistance, hardness reduction, poor stability, etc., to improve flexibility, water resistance, and good water resistance , high gloss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

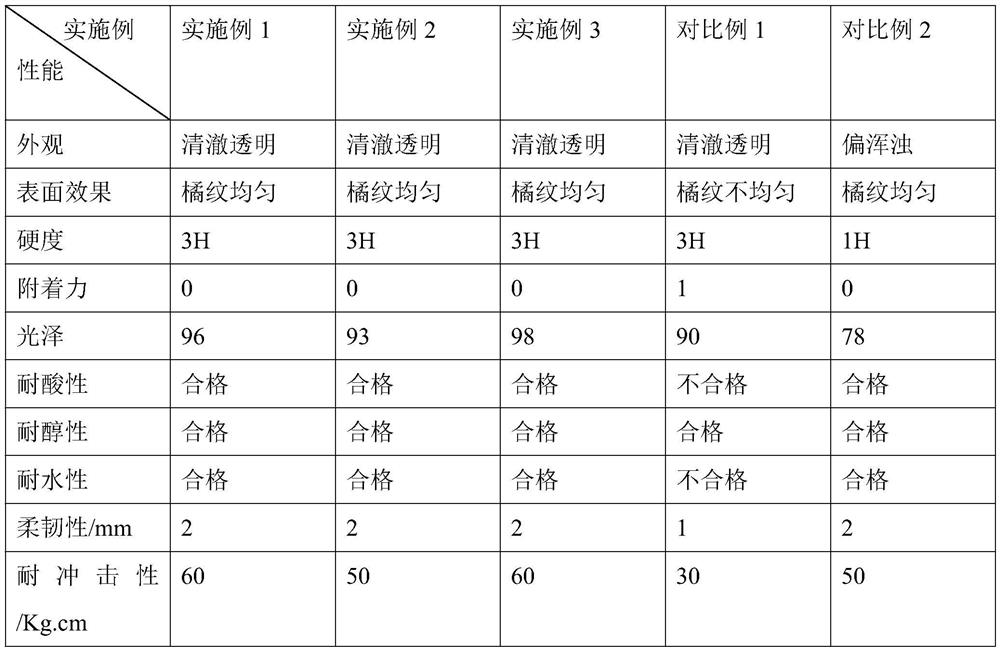

[0023] Embodiment 1: a kind of preparation method of water-based orange pattern epoxy curing agent.

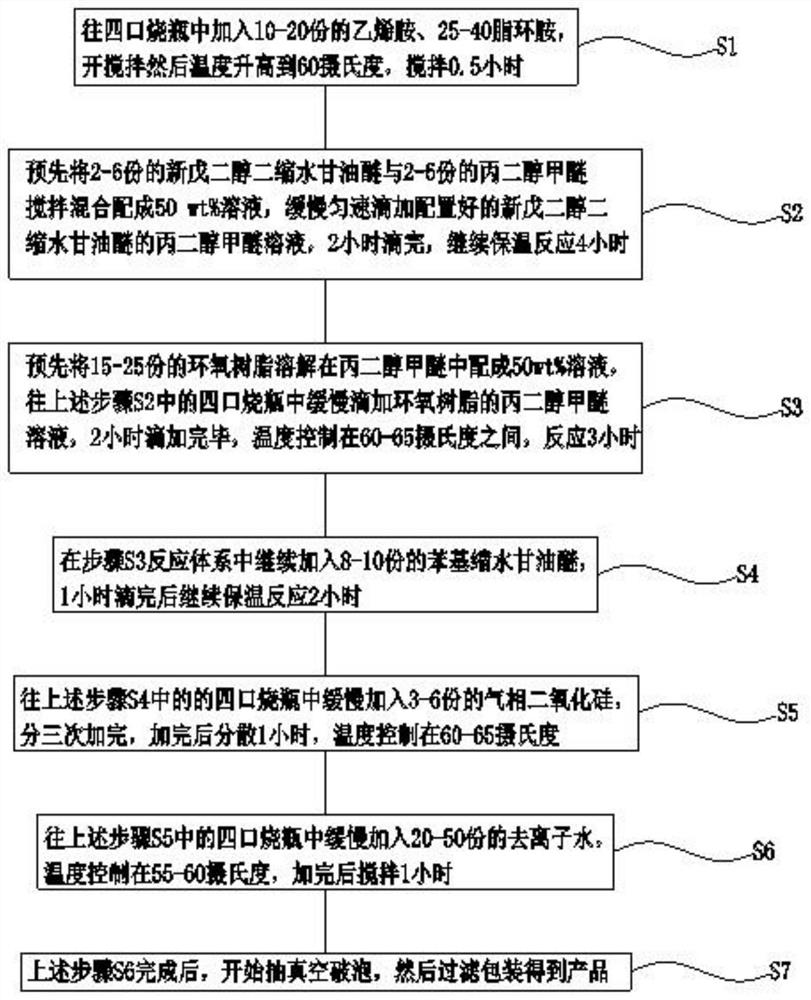

[0024] refer to figure 1 Shown, a kind of preparation method of water-based orange pattern epoxy curing agent, it is prepared by the raw material of following mass parts: the diethylenetriamine of 20 parts, the neopentyl glycol diglycidyl ether of 5 parts, 35 parts IPDA, 127 epoxy resins of 15 parts, 20 parts of propylene glycol methyl ether, 9 parts of phenyl glycidyl ether, 2.5 parts of fumed silica, 27.5 parts of deionized water; specifically include the following steps:

[0025] S1. Add 20 parts of diethylenetriamine and 35 parts of IPDA into the four-necked flask, start stirring, then raise the temperature to 60 degrees Celsius, and stir for 0.5 hours;

[0026] S2. Stir and mix 5 parts of neopentyl glycol diglycidyl ether and 5 parts of propylene glycol methyl ether in advance to form a 50wt% solution, slowly and uniformly drop the prepared propylene glycol methyl ether ...

Embodiment 2

[0033] A preparation method of a water-based orange pattern epoxy curing agent, prepared from the following raw materials in parts by mass: 15 parts of diethylenetriamine, 4 parts of neopentyl glycol diglycidyl ether, 30 parts of HMDA, 20 parts 128 epoxy resins, 24 parts of propylene glycol methyl ether, 8 parts of phenyl glycidyl ether, 5 parts of fumed silica, 30 parts of deionized water; specifically include the following steps:

[0034] S1. Add 15 parts of triethylenetetramine and 30 parts of HMDA into the four-necked flask, start stirring, then raise the temperature to 60 degrees Celsius, and stir for 0.5 hours;

[0035] S2. Stir and mix 4 parts of neopentyl glycol diglycidyl ether and 4 parts of propylene glycol methyl ether in advance to form a 50wt% solution, slowly and uniformly drop the prepared propylene glycol methyl ether solution of neopentyl glycol diglycidyl ether , after 2 hours of dripping, continue to keep warm for 4 hours;

[0036] S3, 20 parts of 128 epox...

Embodiment 3

[0042] A preparation method of a water-based orange pattern epoxy curing agent, prepared from the following raw materials in parts by mass: 18 parts of tetraethylenepentamine, 4 parts of neopentyl glycol diglycidyl ether, 28 parts of MXDA, 17 parts 128 epoxy resins, 21 parts of propylene glycol methyl ether, 8 parts of phenyl glycidyl ether, 4.5 parts of fumed silica, 32.5 parts of deionized water; specifically include the following steps:

[0043] S1. Add 18 parts of tetraethylenepentamine and 28 parts of MXDA into the four-necked flask, start stirring, then raise the temperature to 60 degrees Celsius, and stir for 0.5 hours;

[0044] S2. Stir and mix 4 parts of neopentyl glycol diglycidyl ether and 4 parts of propylene glycol methyl ether in advance to form a 50wt% solution, slowly and uniformly drop the prepared propylene glycol methyl ether solution of neopentyl glycol diglycidyl ether , after 2 hours of dripping, continue to keep warm for 4 hours;

[0045] S3, 17 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com