Chiral azobenzene polymer film as well as preparation method and application thereof

A polymer film and azobenzene technology, applied in the field of chiral azobenzene polymer cross-linked film and its preparation, can solve the problems of high price, limited types of chiral polymers, restricted chiral polymer development and the like, Achieve the effect of avoiding synthesis steps and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example

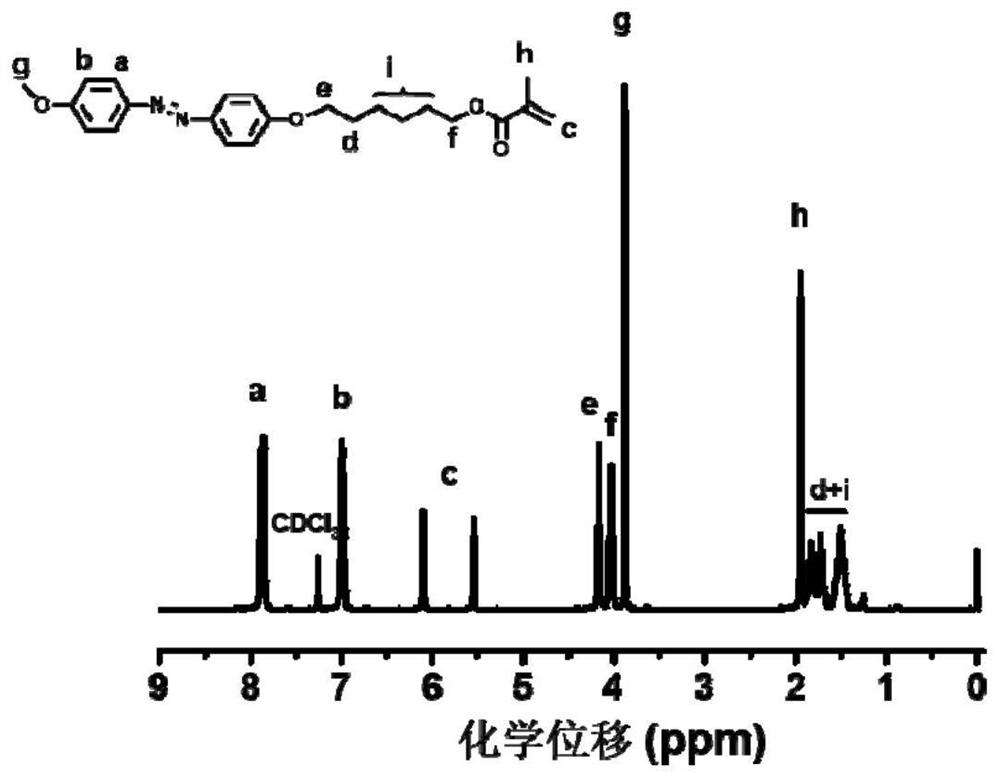

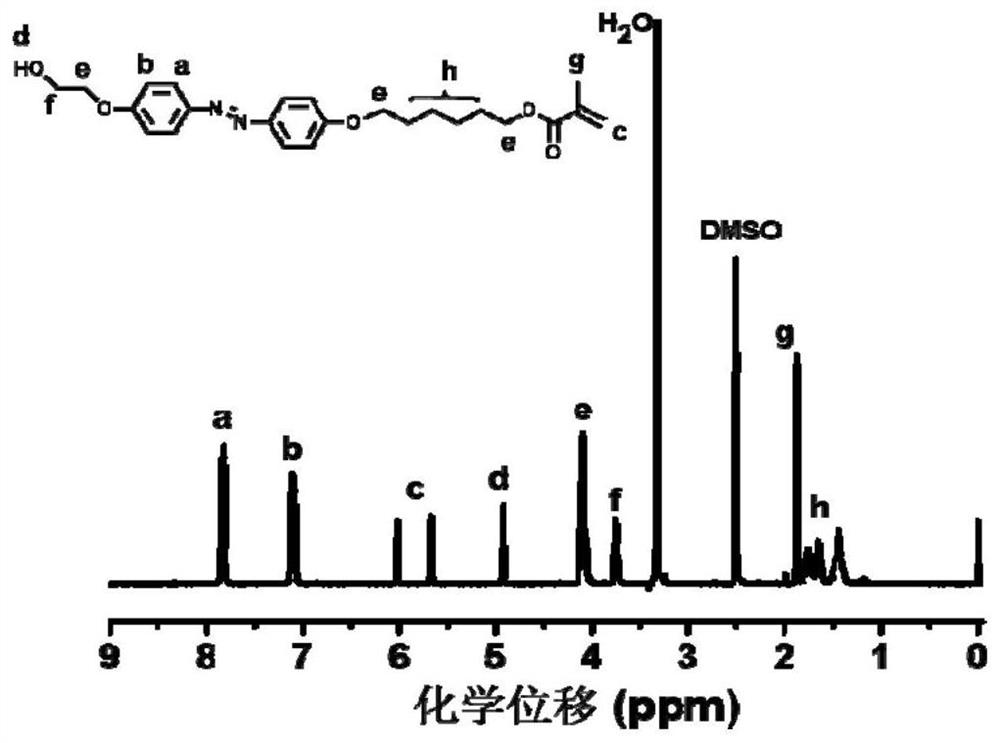

[0102] 1) Synthesis of achiral methoxyazobenzene monomer

[0103] The raw material methoxyaniline (12.32 g, 0.1 mol) and concentrated hydrochloric acid were added to deionized aqueous solution (80 mL), magnetically stirred in an ice-salt bath for 0.5 h, and then 30 mL NaNO 2 (7 g, 0.1 mol / L) aqueous solution, after the dropwise addition, the reaction was continued for 0.5 h in an ice-salt bath to obtain a diazonium salt solution, and the system was red.

[0104] Phenol (16 g, 0.15 mol), NaOH (8 g, 0.2 mol), NaHCO 3 (8.4 g, 0.1 mol) was dissolved in 50 mL of deionized water, under ice-salt bath conditions (control temperature 0-5 °C), mechanically stirred, and then the previously obtained diazonium salt solution of p-methoxyaniline was added dropwise to the above In the phenol solution, the ice-salt bath condition still needs to be maintained at this time, and the solution gradually changes from colorless to yellow, and finally turns into brownish yellow. After the dropwise a...

Embodiment

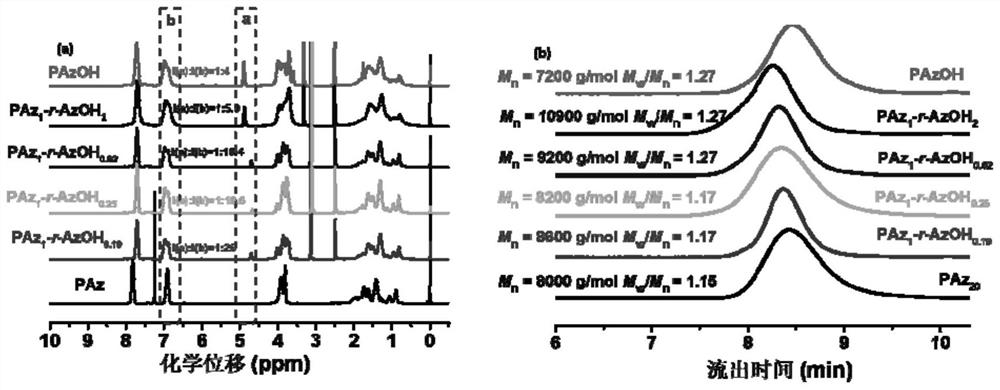

[0121] Preparation of Achiral Azobenzene Polymer Thin Films and Chiral Azobenzene Polymer Thin Films by Chiral Steam Induction

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com