Graphene antistatic low-gasoline-permeability oil delivery pipe and preparation method thereof

A technology of graphene and oil pipelines, which is applied in the field of polymer material composites, can solve the problems of high conductive agent content and poor barrier properties, and achieve the effects of good dispersion, improved dispersion, and thin layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

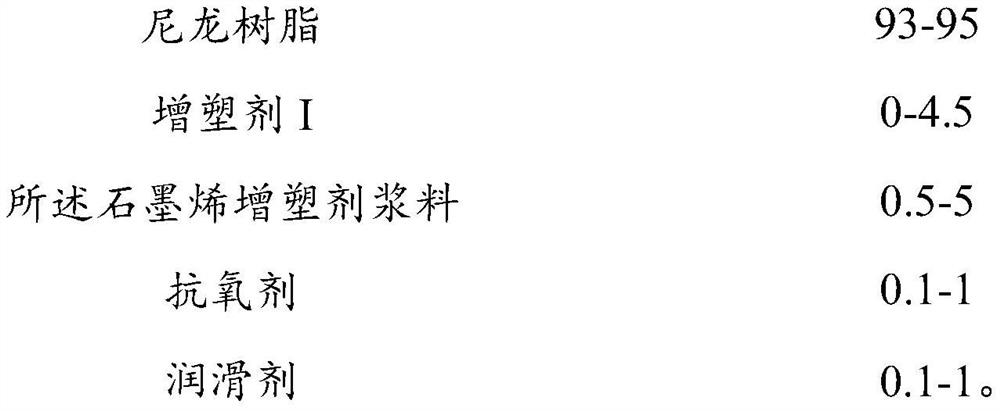

[0046] A graphene conductive PA12 material is applied to automobile oil pipelines, and the parts by mass of each component are as follows:

[0047]

[0048]

[0049] According to the above ratio, put each component in a mixer and mix them for 5-10 minutes, and ensure that the mixing is uniform, and then send the obtained mixture into a twin-screw extruder, and melt it (the barrel temperature of the extruder is 250°C), The screw speed is 400rpm, extruding, water cooling, air drying, and pelletizing to obtain the PA12 composite material. Afterwards, the composite material is directly put into the pipe equipment for pipe production, and the graphene nylon oil delivery pipe provided by the invention is obtained.

[0050] Carry out performance test to the produced graphene PA12 pipe material, fuel oil evaporation is measured airtight chamber test, under SAE J30 test condition, (subsequent examples all adopt this fuel oil penetration test method), the measured performance is a...

Embodiment 2

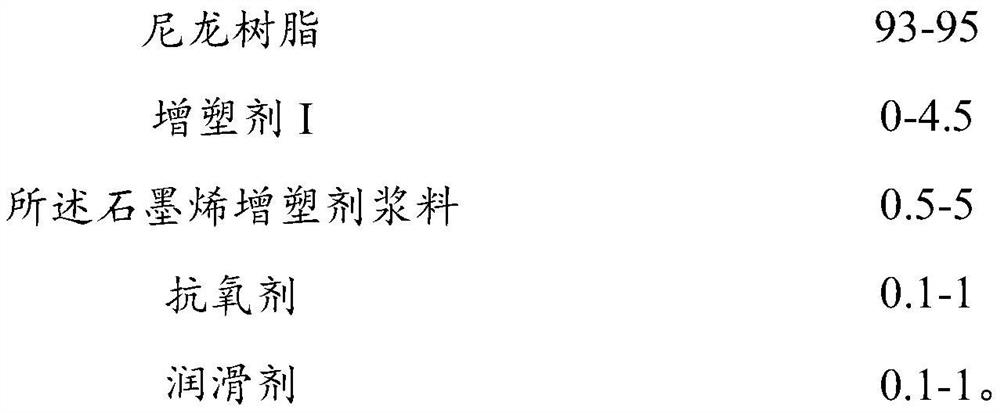

[0056] A graphene conductive PA12 material is applied to automobile oil pipelines, and the parts by mass of each component are as follows:

[0057]

[0058] According to the above ratio, put each component in the mixer and mix them for 5-10 minutes, and ensure that the mixing is uniform, and then send the obtained mixture into a twin-screw extruder, and melt, extrude, water-cool, air-dry, and pelletize. Get PA12 composite material. Afterwards, the composite material is directly put into the pipe equipment for pipe production, and the graphene nylon oil delivery pipe provided by the invention is obtained.

[0059] The measured properties are as follows: 10% ethanol gasoline penetration at 60°C is 5.8g / m 2 / day, compared to 11.5g / m of the blank sample without graphene (other components are identical except graphene) 2 / day decreased by 49.56%, and the sheet graphene greatly improved the barrier property of the pipe to gasoline; the surface resistance was 5.8*10 10 Ω.

[0...

Embodiment 3

[0065] A graphene conductive PA12 material is applied to automobile oil pipelines, and the parts by mass of each component are as follows:

[0066]

[0067] According to the above ratio, put each component in the mixer and mix them for 5-10 minutes, and ensure that the mixing is uniform, and then send the obtained mixture into a twin-screw extruder, and melt, extrude, water-cool, air-dry, and pelletize. Get PA12 composite material. Afterwards, the composite material is directly put into the pipe equipment for pipe production, and the graphene nylon oil delivery pipe provided by the invention is obtained.

[0068] The performance test of the produced graphene PA12 pipe is as follows: 10% ethanol gasoline penetration at 60°C is 9.12g / m 2 / day, compared to 11.5g / m of the blank sample without graphene (other components are identical except graphene) 2 / day decreased by 20.7%; the surface resistance was 3.3*10 11 Ω.

[0069] In this embodiment, the preparation method of used...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com