Processing method of crystalline silicon rod and product thereof

A processing method and technology of crystalline silicon, which are applied in the directions of crystal growth, chemical instruments and methods, single crystal growth, etc., to achieve the effects of improving the pass rate, reducing the line trace rate, and improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

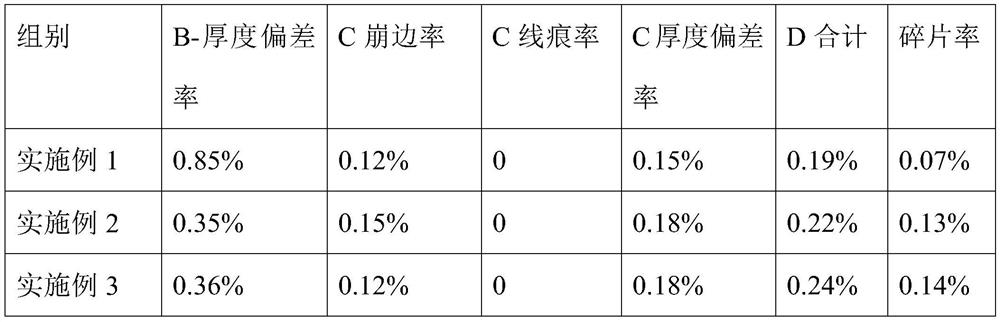

Examples

Embodiment 1

[0041] The present embodiment provides a kind of processing method of crystalline silicon rod, and its operation process is:

[0042](1) Place the ground polysilicon square rod (side length 200mm, length 300mm) into the high-purity quartz powder body with a purity of 99.99%, and place it in the muffle furnace, and flow into the muffle furnace at the same time Argon gas at 20L / min, turn on the heating;

[0043] (2) Firstly, the temperature is raised to 350°C, the heating time is 60 minutes, and the holding time is 20 minutes;

[0044] (3) heat up to 600°C again, and the heating time is 45min;

[0045] (4) The temperature is raised to 1150° C., the heating time is 170 minutes, the holding time is 300 minutes, and finally the heating is turned off for cooling.

Embodiment 2

[0047] The present embodiment provides a kind of processing method of crystalline silicon rod, and its operation process is:

[0048] (1) Put the ground polysilicon square rod (side length 200mm, length 300mm) into the high-purity alumina powder with a purity of 99%, and place it in the muffle furnace, and at the same time, pass it into the muffle furnace Helium with a flow rate of 10L / min, turn on the heating;

[0049] (2) Firstly, the temperature is raised to 300°C, the heating time is 45 minutes, and the holding time is 5 minutes;

[0050] (3) heat up to 500°C again, and the heating time is 15min;

[0051] (4) The temperature is raised to 1000° C., the heating time is 150 minutes, the holding time is 240 minutes, and finally the heating is turned off for cooling.

Embodiment 3

[0053] The present embodiment provides a kind of processing method of crystalline silicon rod, and its operation process is:

[0054] (1) Put the polysilicon square rod (side length 200mm, length 300mm) that has been processed through grinding into a high-purity graphite powder body with a purity of 99.9%, and place it in the muffle furnace, and flow into the muffle furnace at the same time Argon gas at 20L / min, turn on the heating;

[0055] (2) Firstly, the temperature is raised to 400°C, the heating time is 60 minutes, and the holding time is 30 minutes;

[0056] (3) Heating up to 700°C again, the heating time is 60min;

[0057] (4) The temperature is raised to 1000° C., the heating time is 180 minutes, the holding time is 360 minutes, and finally the heating is turned off for cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com