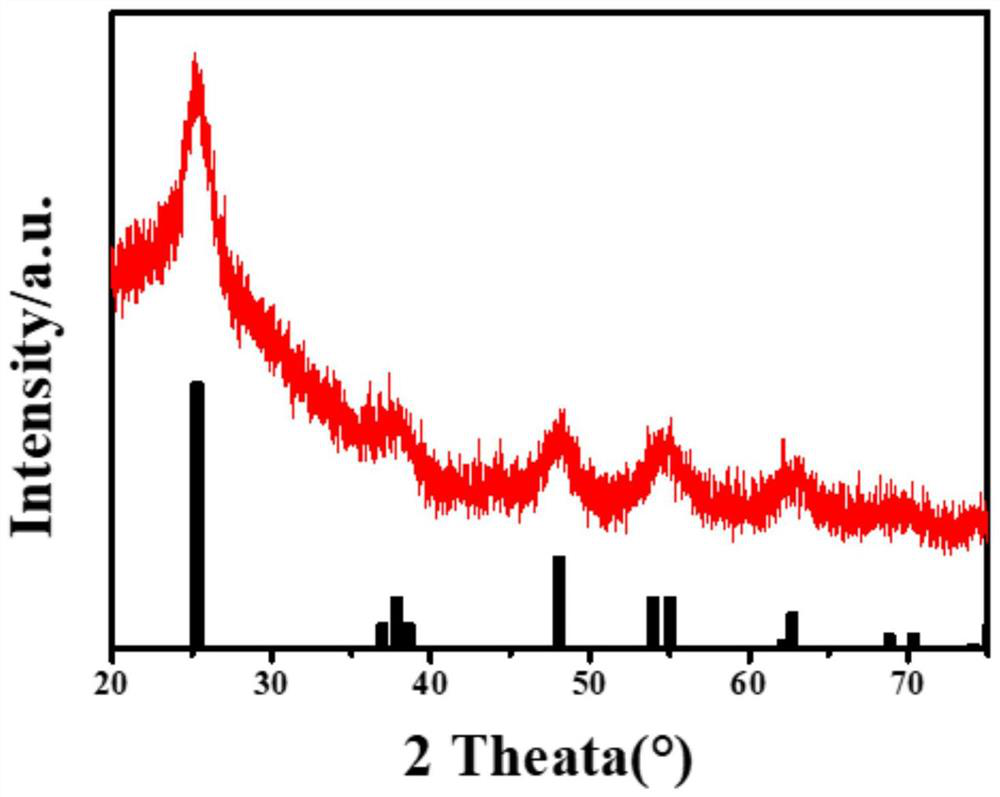

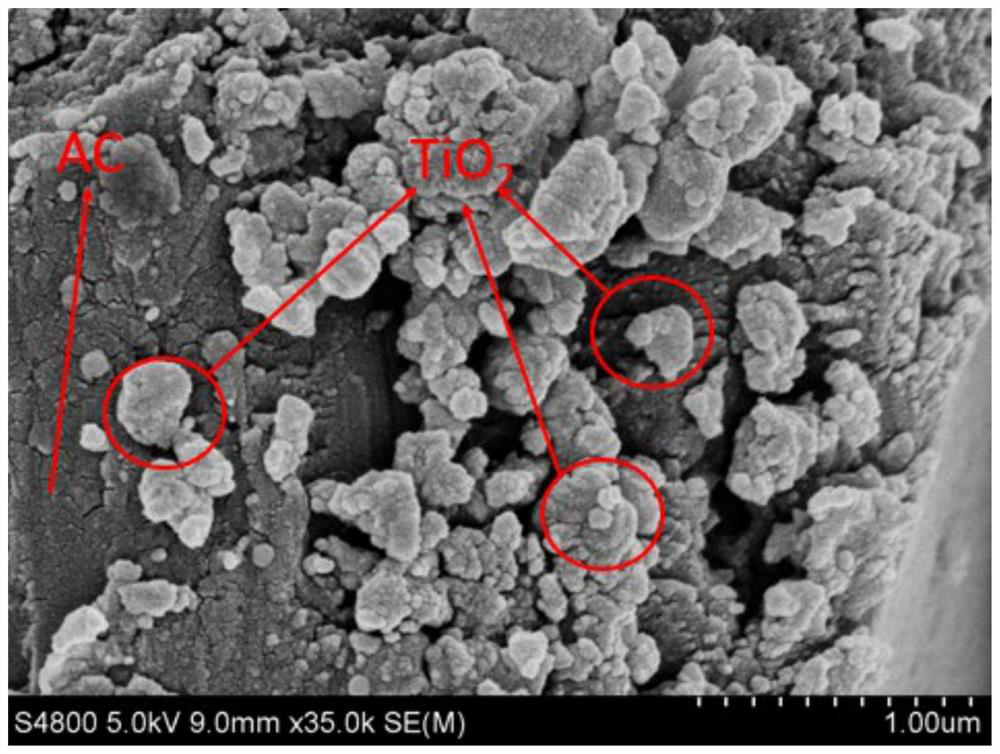

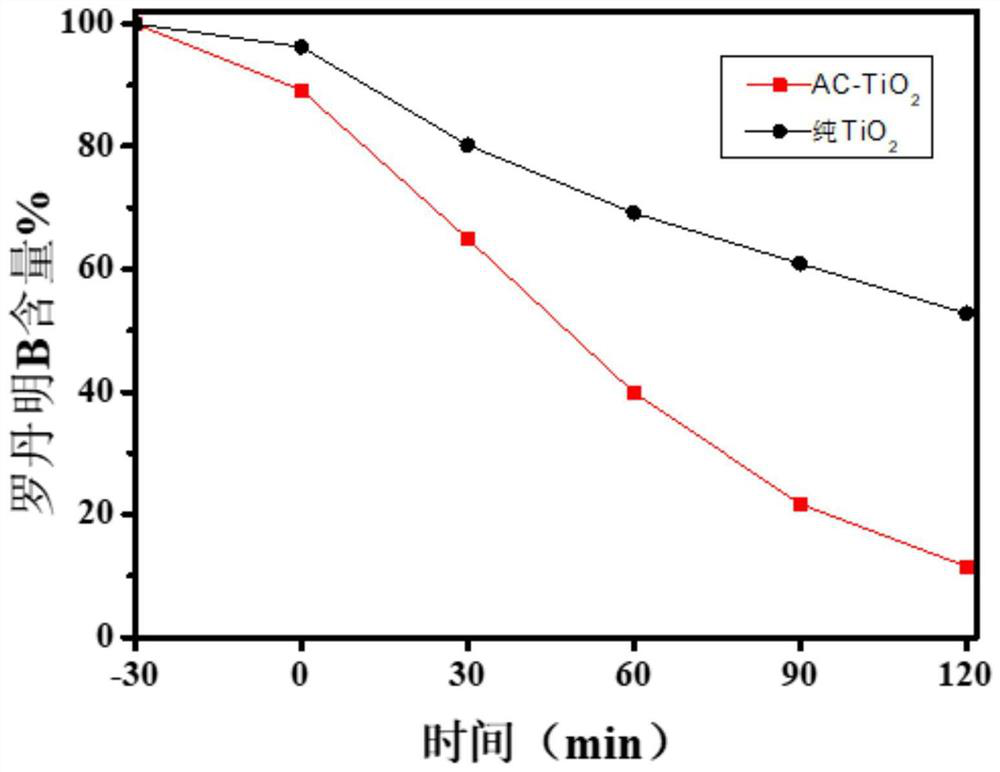

Preparation method of biomimetic synthesis activated carbon-titanium dioxide composite material

A titanium dioxide and activated carbon technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of insignificant industrial wastewater treatment effect, high temperature in the preparation process, unstable connection effect, etc. Increase the probability of effective removal, rich surface functional groups, green environmental protection and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of said AC-TiO 2 The preparation of composite materials, the steps are as follows:

[0038] (1) Dry and sieve Enteromorpha powder in N2 Under protection, carbonize at a high temperature in a tube furnace at 500°C. After cooling to room temperature, add carbonized material and KOH to the carbonized material in a mass ratio of 1:1 and mix evenly, then place the mixture in the tube furnace , pass into N 2 Protection, heat up to 400-550°C, keep warm for 60 minutes, continue to heat up to 650-800°C, keep warm for 90 minutes. Wash with 0.1M hydrochloric acid and ultrapure water in sequence until the pH is about 7, dry and grind the activated carbon product, and seal it for storage.

[0039] (2) Under the condition of constant stirring, take 10 mg of activated carbon in 20 mL of ultrapure water, adjust the pH to 10 with NaOH solution, add 100 μL of APTES under the condition of constant stirring, after stirring for 2 hours, add 100 μL of Ti-BALDH and continue stirring ...

Embodiment 2

[0042] A kind of said AC-TiO 2 The preparation of composite materials, the steps are as follows:

[0043] (1) Carbonize the dried and sieved chlorella powder at a high temperature in a muffle furnace at 500°C, and after cooling to room temperature, add the carbonized material and KOH to the carbonized material in a mass ratio of 1:3 and mix evenly. Then put the mixture in a tube furnace, pass through N2 protection, raise the temperature to 400°C-550°C, keep it for 30 minutes, continue to raise the temperature to 650-800°C, and keep it for 60 minutes. Wash with 0.1M hydrochloric acid and ultrapure water in sequence until the pH is about 7, dry and grind the activated carbon product, and seal it for storage.

[0044] (2) Under the condition of constant stirring, take 10 mg of activated carbon in 20 mL of ultrapure water, adjust the pH to 10 with NaOH solution, add 400 μL of APTES under the condition of continuous stirring, after stirring for 2 hours, add 1000 μL of Ti-BALDH and...

Embodiment 3

[0047] A kind of said AC-TiO 2 The preparation of composite materials, the steps are as follows:

[0048] (1) Carbonize the dried and sieved spirulina powder in a muffle furnace at 450°C at high temperature, and after cooling to room temperature, add KOH to the carbonized material and mix the carbonized material and KOH according to the mass ratio of 1:5, and mix evenly, then Put the mixture in a tube furnace, feed N2 protection, raise the temperature to 400°C-550°C, keep it for 90 minutes, continue to raise the temperature to 650-800°C, and keep it for 60 minutes. Wash with 0.1M hydrochloric acid and ultrapure water in sequence until the pH is about 7, dry and grind the activated carbon product, and seal it for storage.

[0049] (2) Under the condition of constant stirring, take 30 mg of activated carbon in 20 mL of ultrapure water, adjust the pH to 10 with NaOH solution, add 500 μL of APTES under the condition of constant stirring, after stirring for 2 hours, add 1000 μL of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com