Harmless treatment method for cyanide-containing and heavy metal-containing wastewater in gold smelting

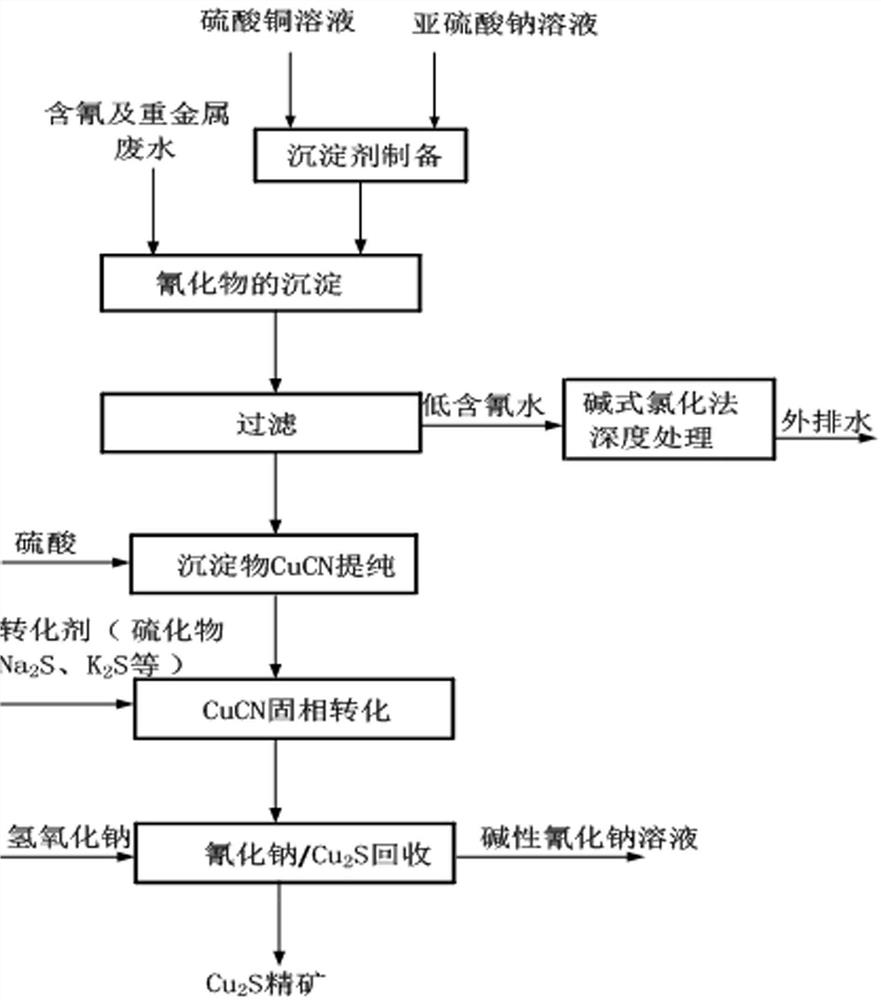

A harmless treatment, heavy metal technology, applied in the direction of metallurgical wastewater treatment, metal cyanide, water/sewage treatment, etc., can solve the problems of large water quality fluctuations, complex treatment process, not simple enough operation, etc., to achieve easy automatic control , good safety and controllability, and strong process adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

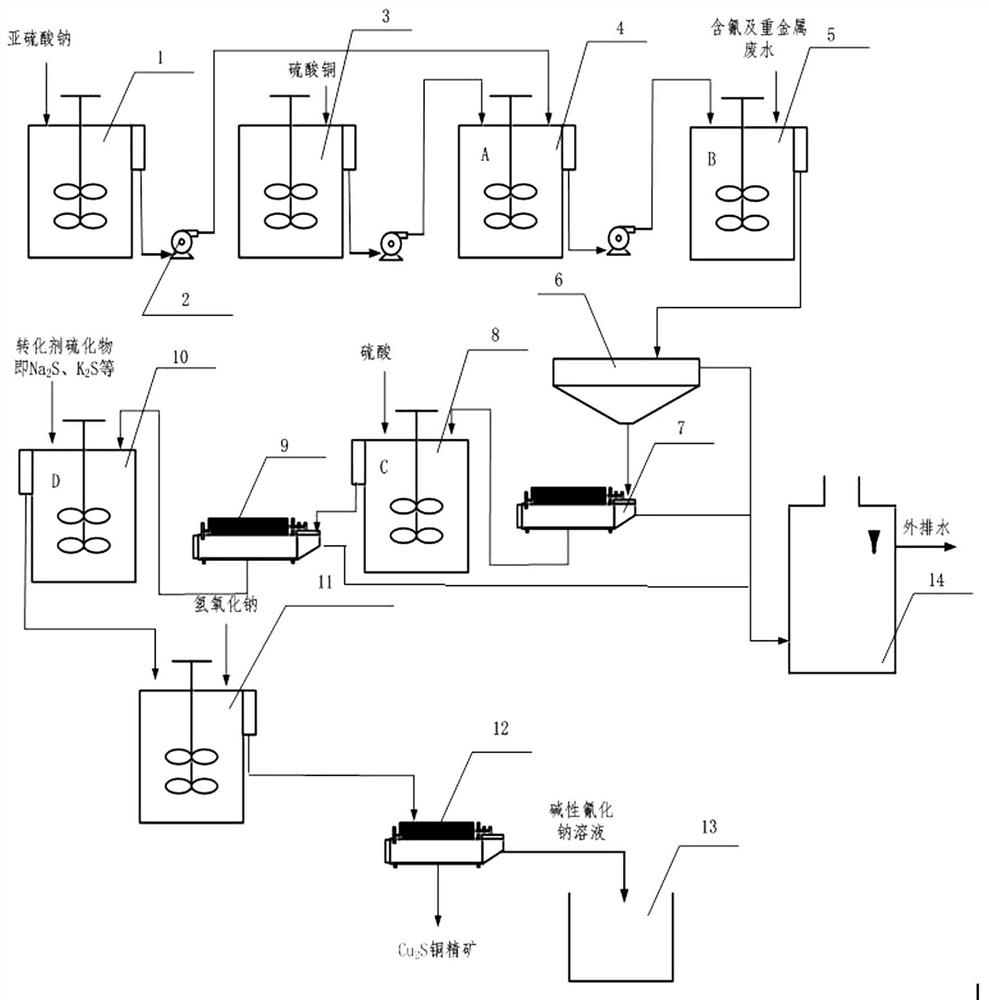

[0037] (2) Preparation of precipitant solution. Transfer a certain amount of prepared copper sulfate solution to the preparation tank A; at the same time, add a certain amount of alkali, such as sodium hydroxide or sodium carbonate, to the prepared sodium sulfite solution to adjust the solution to alkaline, and control the pH = 9~10, and then transported to the preparation barrel A by a pump, and reacted with the copper sulfate solution. In this process, the amount of sodium sulfite, according to the chemical reaction equation 2Cu 2+ +SO 3 2- +2OH - =2Cu + +SO 4 2- +H 2 After the theoretical amount is calculated, the addition control is carried out at 1.1 to 1.3 times the theoretical amount to obtain a cuprous solution precipitant;

[0038] A certain amount of gold smelting wastewater containing cyanide and heavy metals is transported to the reaction tank B, and then the cuprous solution prepared according to the above step (2) is pumped into the reaction tank B to rea...

Embodiment 1

[0051] A gold smelting waste water containing cyanide and heavy metals, the pH of the solution is about 9~10, the analysis results of the main harmful elements are: 1768.58mg / L total cyanide, 150.45mg / L free cyanide, 1626.85mg / L copper, 1626.85mg / L copper, Iron 0.45mg / L, also contains a certain amount of calcium, magnesium and other elements.

[0052] Adopt the present invention to implement this gold smelting wastewater containing cyanide and heavy metals, and the technical scheme includes:

[0053] (1) Detection of total cyanide and heavy metal content in gold smelting wastewater. Take a certain amount of wastewater containing cyanide and heavy metals from gold smelting to be treated, and measure the contents of cyanide, copper, zinc, iron and other elements respectively;

[0054] (2) Preparation of precipitant solution. Transfer a certain amount of prepared copper sulfate solution to the preparation tank A; at the same time, add a certain amount of alkali, such as sodium ...

Embodiment 2

[0067] A gold smelting waste water containing cyanide and heavy metals. The pH of the solution is about 9~10. The analysis results of the main harmful elements are: 2477.65 mg / L of total cyanide, 180.27 mg / L of free cyanide, 2305.36 mg / L of copper, and 2305.36 mg / L of copper. Iron 0.57mg / L, also contains a certain amount of calcium, magnesium and other elements.

[0068] Adopt the present invention to implement this gold smelting wastewater containing cyanide and heavy metals, and the technical scheme includes:

[0069] (1) Detection of total cyanide and heavy metal content in gold smelting wastewater. Take a certain amount of wastewater containing cyanide and heavy metals from gold smelting to be treated, and measure the contents of cyanide, copper, zinc, iron and other elements respectively;

[0070] (2) Preparation of precipitant solution. Transfer a certain amount of prepared copper sulfate solution to the preparation tank A; at the same time, add a certain amount of alk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com