Oil-based drilling fluid viscosity reducer as well as preparation method and application thereof

A technology of oil-based drilling fluid and viscosity reducer, which is applied in the field of drilling, can solve the problems of increasing the risk of shale well wall instability, unsatisfactory high temperature resistance, and oil-based drilling fluid demulsification, etc., achieving obvious economy and practicality properties, obvious viscosity-reducing effect, and good wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

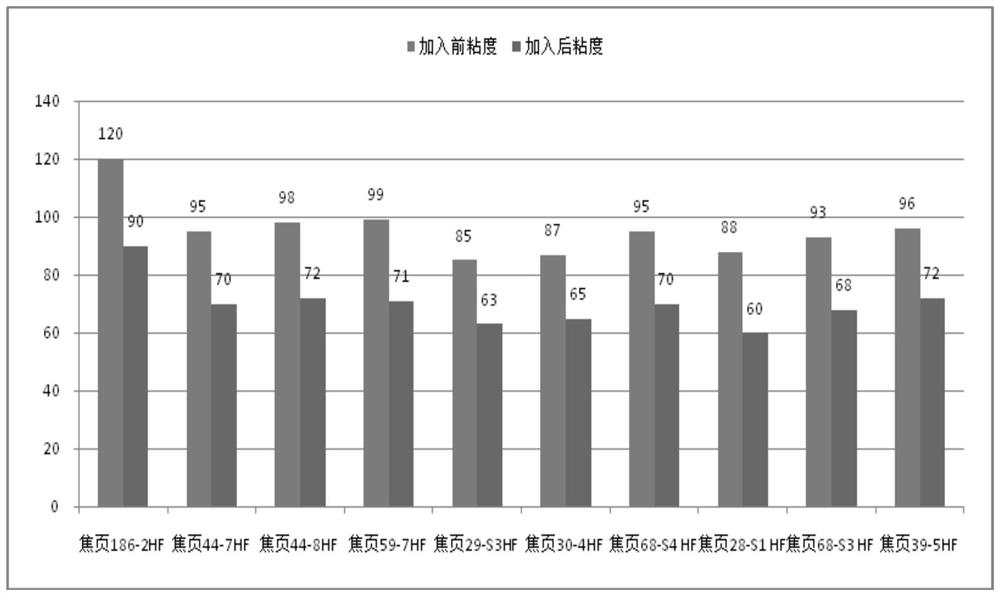

Image

Examples

preparation example Construction

[0041] As a further embodiment, the preparation method of gemini cationic surfactant comprises the steps:

[0042] In a three-necked flask equipped with a reflux condenser, add acetonitrile, dioctadecylmethyl tertiary amine, n-hexadecane bromide and hexadecane chloride in the prescribed amount, and pass nitrogen gas for 20-30 minutes to exclude oxygen , to prevent the tertiary amine from being oxidized; stir at 75-85°C for 10-12 hours; then add the formulated amount of isopropanol, ethyl acetate, and toluene to react to obtain a viscous gemini cationic surfactant.

[0043] As a further embodiment, the nonionic surfactant includes the following components by weight:

[0044] 1 part of phenyl alkylbenzenesulfonate, 2 parts of tripolyglycerol monolaurate, 0.5 part of trimethylolpropane trioleate, 2 parts of oleic acid amide.

[0045] As a further embodiment, the solvent oil is No. 3 white oil, No. 5 white oil, d40 solvent oil, No. 70 solvent oil, No. 90 solvent oil, No. 120 solv...

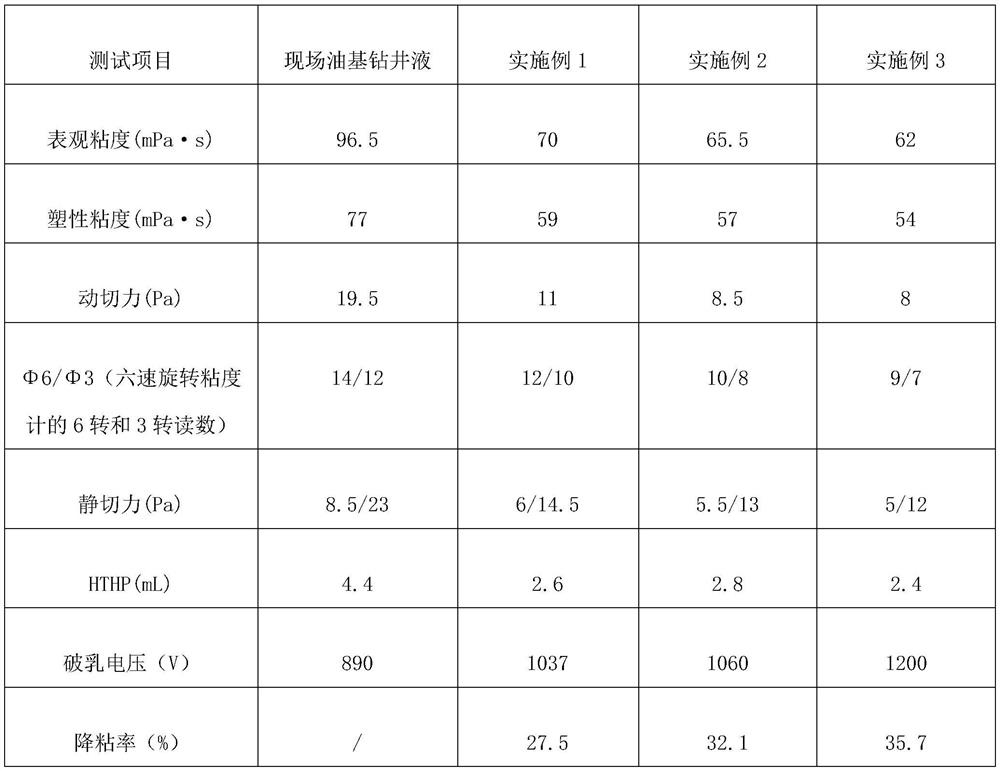

Embodiment 1

[0051] An oil-based drilling fluid viscosity reducer, comprising the following components in parts by weight: 70 parts of solvent naphtha, 20 parts of surfactant, 7 parts of penetrating agent, and 3 parts of stabilizer.

[0052] Surfactants include gemini cationic surfactants and nonionic surfactants, and the mass ratio of gemini cationic surfactants to nonionic surfactants is 1:1.

[0053] Gemini cationic surfactants include the following components by weight: 15 parts of dioctadecylmethyl tertiary amine, 4 parts of n-hexadecane bromide, 1 part of hexadecane chloride, 2 parts of acetonitrile, 1 part of isopropanol parts, 0.5 parts of ethyl acetate, and 5 parts of toluene.

[0054] The preparation method of gemini cationic surfactant comprises the following steps: in a three-necked flask equipped with a reflux condenser, add a formula amount of acetonitrile, dioctadecylmethyl tertiary amine, n-hexadecane bromide and decachloride Hexane, blow nitrogen for 30 minutes, stir at 8...

Embodiment 2

[0063] An oil-based drilling fluid viscosity reducer, comprising the following components in parts by weight: 50 parts of solvent naphtha, 10 parts of surfactant, 1 part of penetrant, and 10 parts of stabilizer.

[0064] Surfactants include gemini cationic surfactants and nonionic surfactants, and the mass ratio of gemini cationic surfactants to nonionic surfactants is 1:1.

[0065] Gemini cationic surfactants include the following components by weight: 15 parts of dioctadecylmethyl tertiary amine, 4 parts of n-hexadecane bromide, 1 part of hexadecane chloride, 2 parts of acetonitrile, 1 part of isopropanol parts, 0.5 parts of ethyl acetate, and 5 parts of toluene.

[0066] The preparation method of gemini cationic surfactant comprises the following steps: in a three-necked flask equipped with a reflux condenser, add a formula amount of acetonitrile, dioctadecylmethyl tertiary amine, n-hexadecane bromide and decachloride Hexane, blow nitrogen for 25 minutes, stir at 85°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com