Magnetic core-shell microcapsule generation method based on surface acoustic wave microfluidic device

A technology of a microfluidic device and a core-shell microcapsule, which is applied in the field of microfluidics, can solve the problems of affecting the precise control of the core-shell structure, affecting the flow rate, time difference, etc. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is described in detail below in conjunction with accompanying drawing.

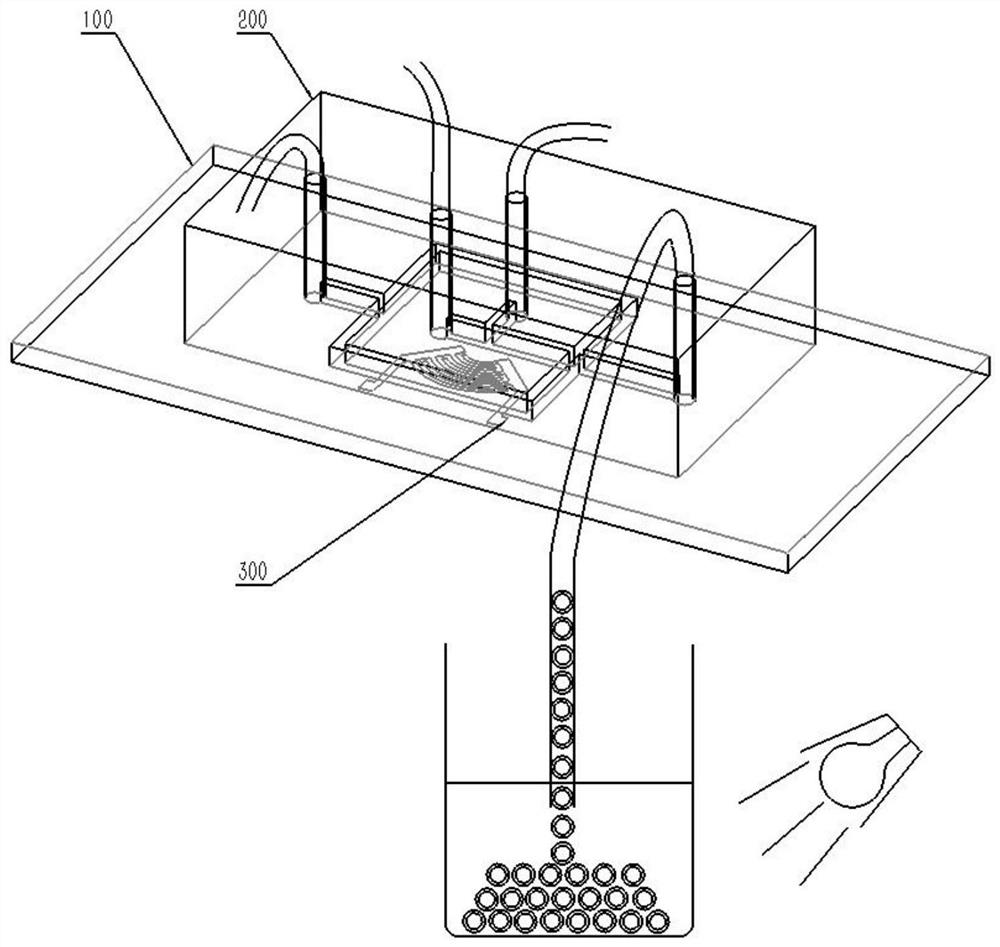

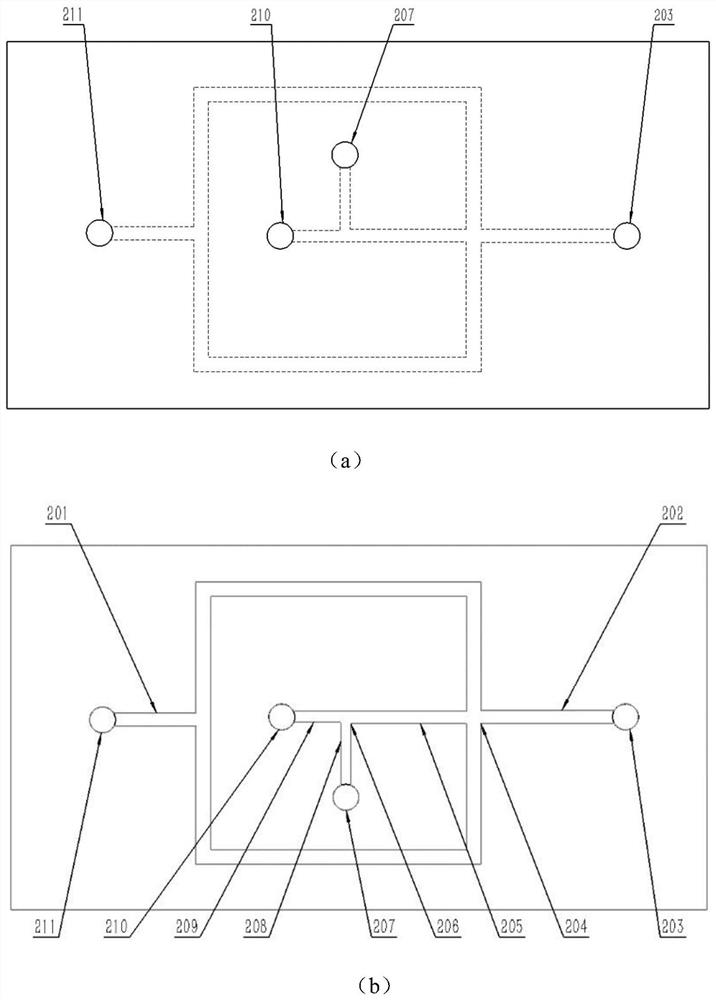

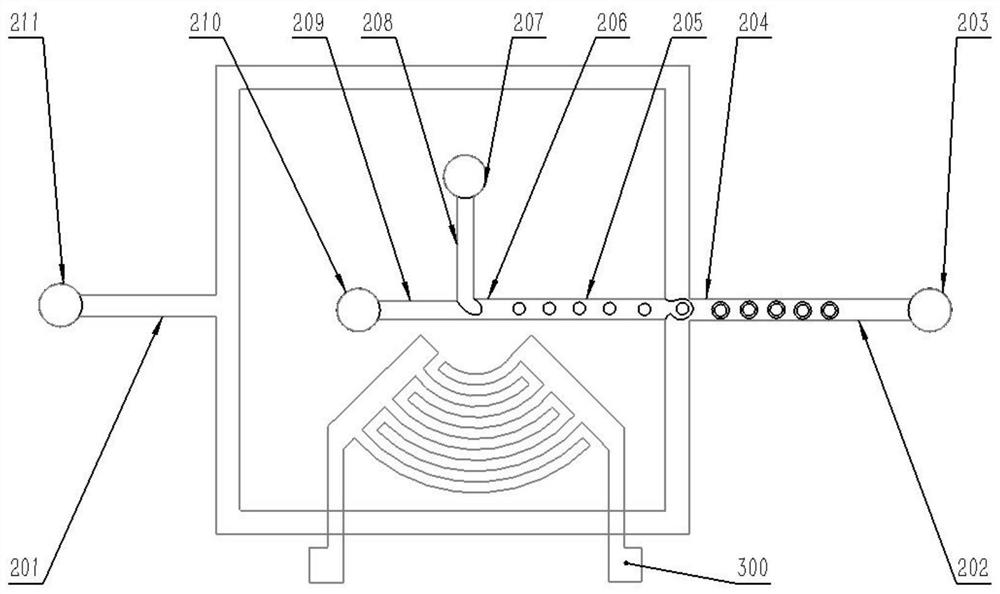

[0032] A method for generating magnetic core-shell microcapsules based on a surface acoustic wave microfluidic device, including a surface acoustic wave microfluidic device and a collection and solidification system, referring to figure 1 , the surface acoustic wave microfluidic device includes a piezoelectric substrate 100, a group of arc-shaped interdigital transducers 300 are arranged on the piezoelectric substrate 100, a PDMS microchannel system 200 is attached to the upper part of the piezoelectric substrate 100, and the PDMS microchannel The system 200 and the piezoelectric substrate 100 form a closed flow channel; the collection and curing system allows the generated core-shell droplets to flow into the glass bottle through the collection pipe, and form magnetic core-shell microcapsules after being irradiated by ultraviolet light; The power of the lamp is 2 watts, and i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com