Bamboo-based fiber composite material and continuous preparation method thereof

A technology of fiber composite materials and bamboo-based materials, applied in wood compression, wood impregnation, manufacturing tools, etc., can solve the problems of low production efficiency, complicated preparation methods, and inability to realize continuous production, and achieve high production efficiency and preparation methods Simple and easy to use, with good anti-mildew and anti-insect effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

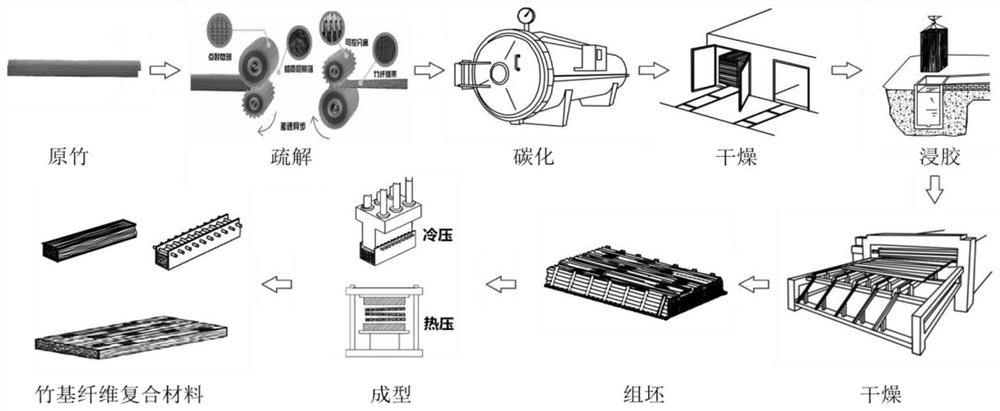

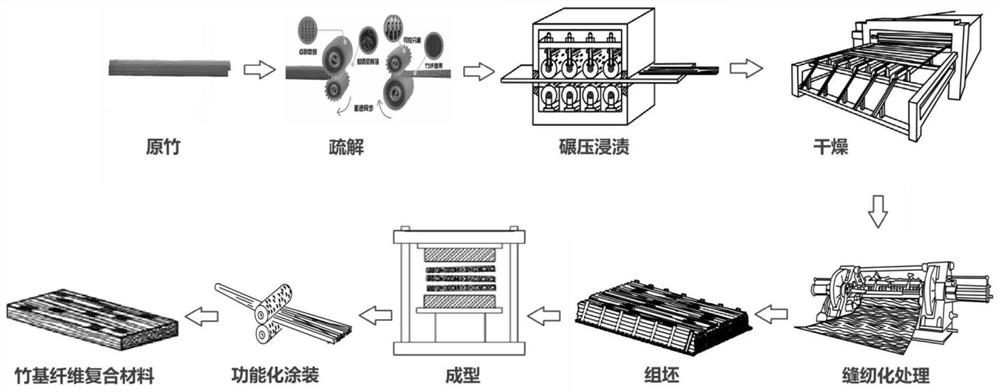

[0050] A first aspect of the present invention provides a method for preparing a bamboo-based fiber composite material, the bamboo-based fiber composite material comprising a plurality of bamboo fiberized veneers, comprising the following steps:

[0051] The bamboo fiberized veneer is rolled and impregnated with an adhesive to obtain an impregnated product;

[0052] drying the impregnated product to obtain a dried product;

[0053] After sewing the dried product, at least the first bamboo-based material and the second bamboo-based material are obtained;

[0054] The first bamboo-based material and the second bamboo-based material are assembled to obtain a molded body;

[0055] Hot pressing the molded body to obtain a bamboo-based fiber composite material blank;

[0056] The bamboo-based fiber composite material is obtained by performing functionalization post-processing on the bamboo-based fiber composite material blank.

[0057]

[0058] The bamboo fiberized veneers are ...

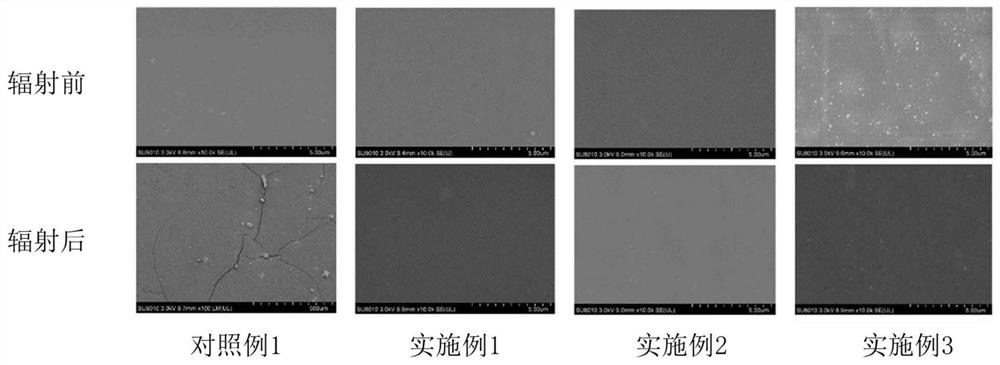

Embodiment 1

[0103] The bamboo wood is decomposed into bamboo fiber veneer, the width of the bamboo fiber veneer is 10cm, and the moisture content is 35%. Then, the fibrous veneer is rolled and then impregnated in the adhesive with an adhesive, and then rolled to obtain an impregnated product. Among them, the rolling pressure is 20MPa. The adhesive is an aqueous solution of water-soluble impregnated phenolic resin, wherein the mass concentration of water-soluble impregnated phenolic resin is 30%; ) accounted for 15% of the mass content of the impregnated product after rolling.

[0104] Then, the impregnated product is dried by a mesh belt dryer, the drying temperature is 70° C., and the drying time is 80 min to obtain a dried product. After drying, the moisture content of the dried product was 12%.

[0105] The dried products are arranged in parallel and then subjected to a whole-sheet sewing process to obtain a bamboo-based material. Wherein, in the sewing process, the sewing thread u...

Embodiment 2

[0110] The bamboo is decomposed into bamboo fibrous veneer, the width of the bamboo fibrous veneer is 10cm, the moisture content is 35%, and then the fibrous veneer is rolled and dipped in the adhesive by using an adhesive, Roll compaction is then carried out to obtain an impregnated product. Among them, the rolling pressure is 15MPa. The adhesive is an aqueous solution of water-soluble impregnated phenolic resin, wherein the mass concentration of water-soluble impregnated phenolic resin in the adhesive is 25%. After rolling, the water content of the impregnated product is 24.30%, and the content of water-soluble impregnated phenolic resin ( 100%) accounts for 15% of the content of the bamboo-based material after rolling. Then, the impregnated product is dried by a mesh belt dryer, the drying temperature is 70° C., and the drying time is 60 min to obtain a dried product. After drying, the moisture content of the dried product was 12%.

[0111] The dried products are arrange...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com