Method for recycling ammonium paratungstate by using waste SCR catalyst

A technology of SCR catalyst and ammonium paratungstate, which is applied in chemical instruments and methods, preparation of vanadium compounds, preparation of tungsten compounds, etc., can solve the problems of wasting lye, high cost of chemicals, and no purification process for titanium dioxide filter residues, so as to save production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

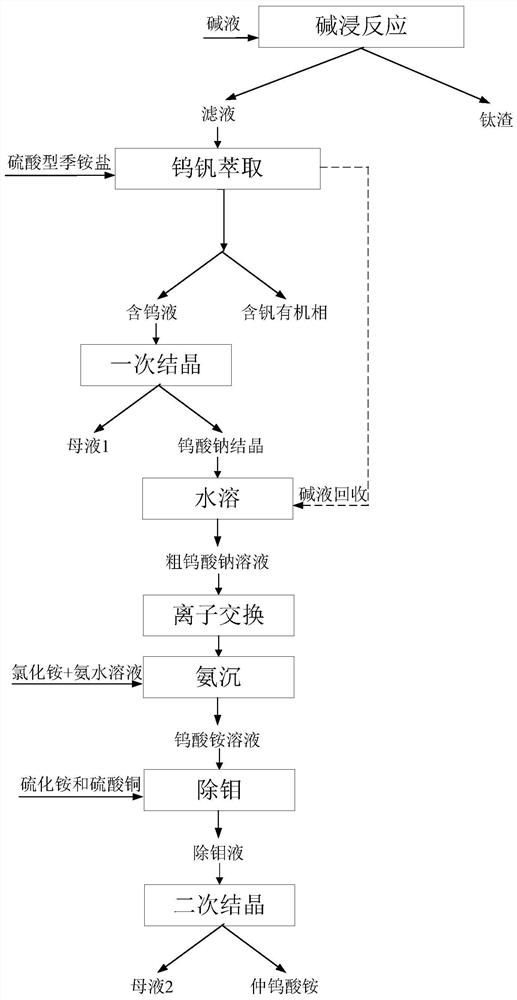

Embodiment 1

[0036] (1) Alkali leaching reaction: Alkali leaching reaction is carried out on the crushed and ground spent SCR denitration catalyst powder, and titanium slag and filtrate are obtained by filtration.

[0037] (2) Extraction of tungsten and vanadium: use sulfuric acid quaternary ammonium salt to carry out tungsten and vanadium extraction on the filtrate after step (1), to obtain tungsten-containing liquid and vanadium-containing organic phase, wherein the ratio of sulfuric acid quaternary ammonium salt is O / A =1:1, the temperature is 10-30 degrees, the pH of the feed liquid is 9-12, and the single-stage extraction rate is 98%.

[0038] (3) Primary crystallization: Carry out crystallization operation on the tungsten-containing liquid to obtain mother liquid 1 and sodium tungstate crystals. Among them, the specific gravity of crystallization and mother liquid is controlled to be 1.60 mg / L during the primary crystallization process, and the NaOH content of mother liquid 1 is 600-7...

Embodiment 2

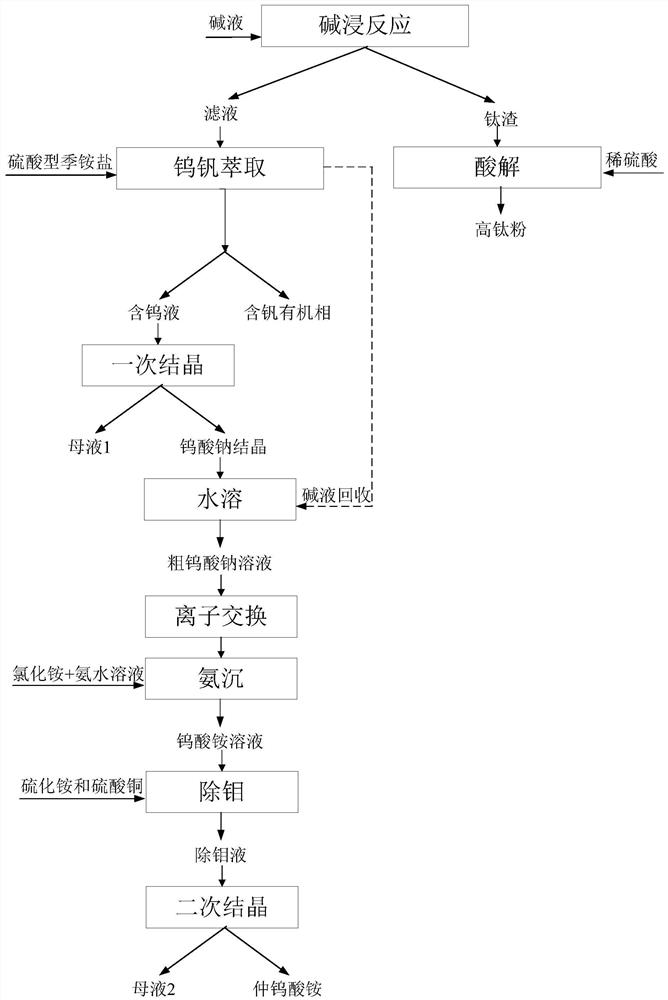

[0047] On the basis of the above-mentioned embodiments, the embodiments of the present application further elaborate the steps, as figure 2 As shown, in addition to the extraction of ammonium paratungstate, it also includes the extraction of titanium powder.

[0048] (1) Alkali leaching reaction: Alkali leaching reaction is carried out on the crushed and ground spent SCR denitration catalyst powder, and titanium slag and filtrate are obtained by filtration.

[0049] (10) Acidolysis: use dilute sulfuric acid to acidolyze the titanium slag treated in step (1) to obtain high-titanium powder. Wherein, the concentration of the dilute sulfuric acid in step (10) is 2-8%, and the purity of the high-titanium powder is more than or equal to 95%.

[0050]In the embodiment of the present application, on the basis of the above-mentioned embodiments, not only the recycling of alkali solution is realized, but also the recovery of titanium powder by acidolysis of the waste titanium slag aft...

Embodiment 3

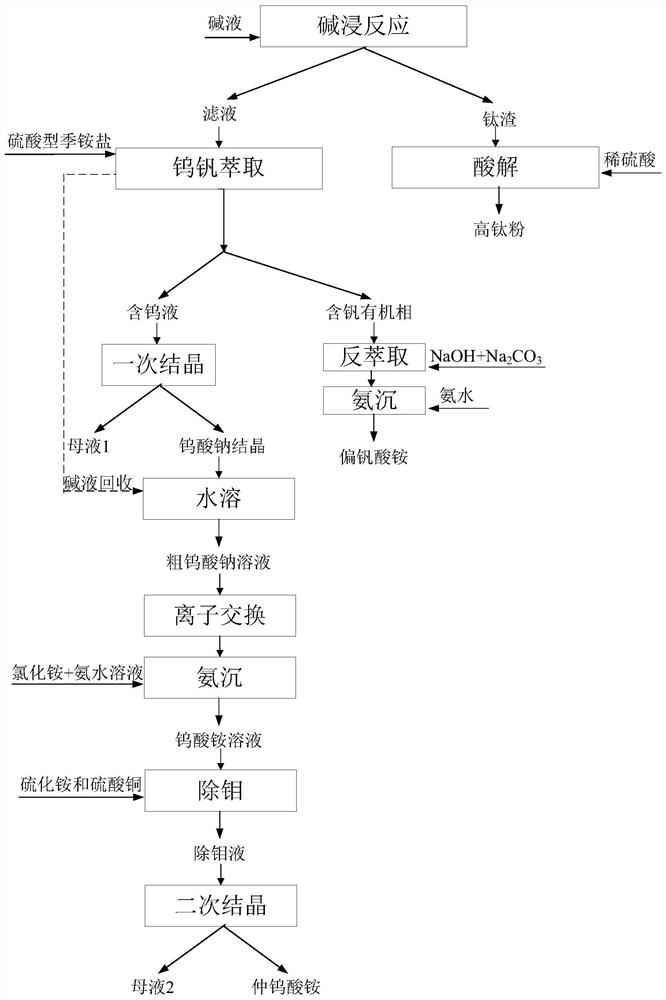

[0052] On the basis of the above-mentioned embodiments, the embodiments of the present application further elaborate the steps, as image 3 As shown, in addition to the extraction of ammonium paratungstate and titanium powder, it also includes the extraction of ammonium metavanadate.

[0053] (1) Alkali leaching reaction: Alkali leaching reaction is carried out on the crushed and ground spent SCR denitration catalyst powder, and titanium slag and filtrate are obtained by filtration.

[0054] (2) Extraction of tungsten and vanadium: extracting tungsten and vanadium from the filtrate treated in step (1) with sulfuric acid quaternary ammonium salt to obtain a tungsten-containing liquid and a vanadium-containing organic phase.

[0055] (11) Stripping: use 0.5mol / L NaOH and 1.5mol / L Na 2 CO 3 Back-extracting the vanadium-containing organic phase after the treatment in step (2).

[0056] (12) Ammonia precipitation: Precipitate the material after step (11) stripping with ammonia w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com