Sludge dewatering and drying process technology and dewatering and drying system

A technology of sludge dehydration and process technology, which is applied in the direction of sludge detoxification, water/sludge/sewage treatment, sludge treatment, etc. It can solve the problems of unfavorable transportation and disposal, easy corruption and odor, and high microwave energy consumption. Achieve the effects of reducing weight and volume, reducing moisture content, and being environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

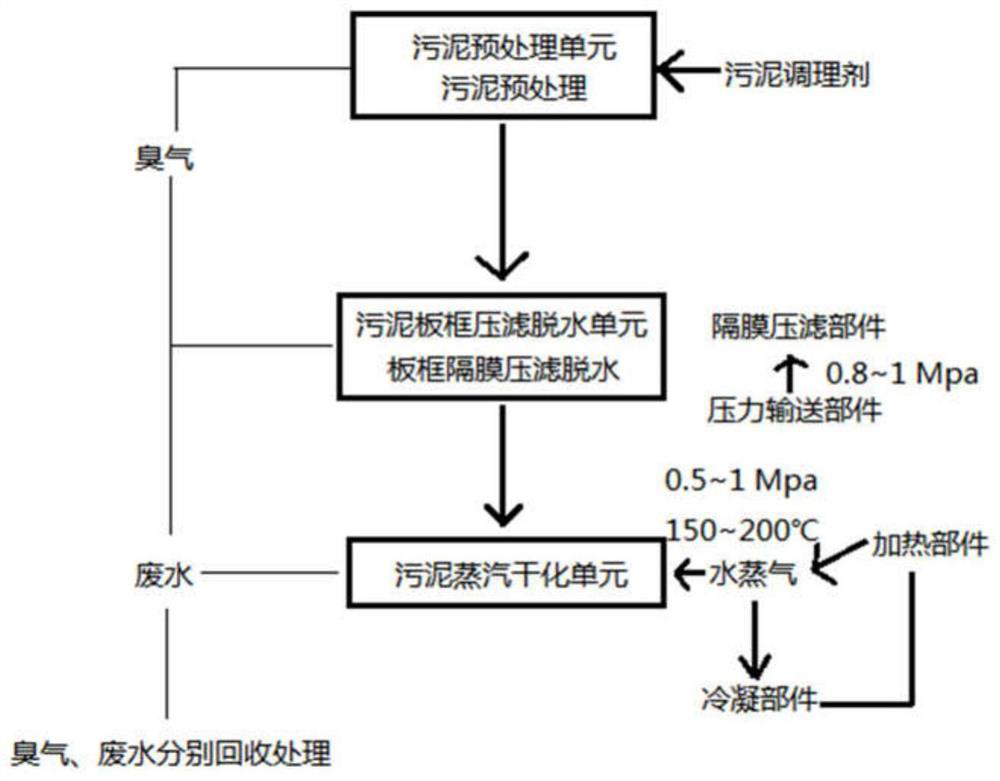

Image

Examples

Embodiment 1

[0031] Choose 5 tons of sludge from a certain water purification plant, with a water content of 89%, and use the dehydration and drying process and system of the present invention to process it. The method is as follows:

[0032] A sludge dehydration and drying process technology and dehydration and drying system:

[0033] 1) Sludge pretreatment unit: pretreat the sludge, that is, collect the sludge and treat it separately, and use the sludge conditioner to dehydrate the sludge and sterilize it. The amount of the conditioner added is 10% of the sludge, the sludge is stirred evenly and slowly, and the conditioning time is 1h;

[0034] The sludge conditioner is a mixture of polyaluminum chloride, polyacrylamide, waste dried organisms and biological enzymes, and the ratio of use is 1:5:2:1;

[0035] The waste dried organisms include cassava and straw 1:2;

[0036] The biological enzyme is cellulase and β-amylase, and its usage ratio is 1:3;

[0037] The moisture content of the...

Embodiment 2

[0041] A sludge dehydration and drying process technology and dehydration and drying system:

[0042] 1) Sludge pretreatment unit: pretreat the sludge, that is, collect the sludge and treat it separately, and use the sludge conditioner to dehydrate the sludge and sterilize it. The amount of the conditioner added is 10% of the sludge, the sludge is stirred evenly and slowly, and the conditioning time is 1h;

[0043] The sludge conditioner is a mixture of polyaluminium chloride, polyacrylamide, waste dried organisms and biological enzymes, and the ratio of use is 2:3:1:1;

[0044] The waste dried organisms include cassava and straw 1:2;

[0045] The biological enzyme is cellulase and β-amylase, and its usage ratio is 3:2;

[0046] The moisture content of the pretreated sludge is 71.56%;

[0047] 2) Sludge plate and frame filter press dehydration unit: including a plate and frame diaphragm filter press part and a pressure delivery part, the pressure delivery part is to change ...

Embodiment 3

[0050] A sludge dehydration and drying process technology and dehydration and drying system:

[0051]1) Sludge pretreatment unit: pretreat the sludge, that is, collect the sludge and treat it separately, and use the sludge conditioner to dehydrate the sludge and sterilize it. The amount of the conditioner added is 10% of the sludge, the sludge is stirred evenly and slowly, and the conditioning time is 1h;

[0052] The sludge conditioner is a mixture of polyaluminum chloride, polyacrylamide, waste dried organisms and biological enzymes, and the ratio of use is 3:2:3:2;

[0053] The waste dried organisms include cottonseed meal, straw and leaves in a ratio of 1:1:1;

[0054] The biological enzyme is cellulase and β-amylase, and its usage ratio is 1:3;

[0055] The moisture content of the pretreated sludge is 75.65%;

[0056] 2) Sludge plate and frame filter press dehydration unit: including a plate and frame diaphragm filter press part and a pressure delivery part, the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com