Modified phthalonitrile resin and preparation method thereof

A technology of phthalonitrile resin and phthalonitrile, which is applied in the field of phthalonitrile resin modification, can solve the problems of poor heat resistance, poor compatibility, and influence on mechanical properties of the resin, and improve the toughness of the resin , Improve compatibility, improve the effect of shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

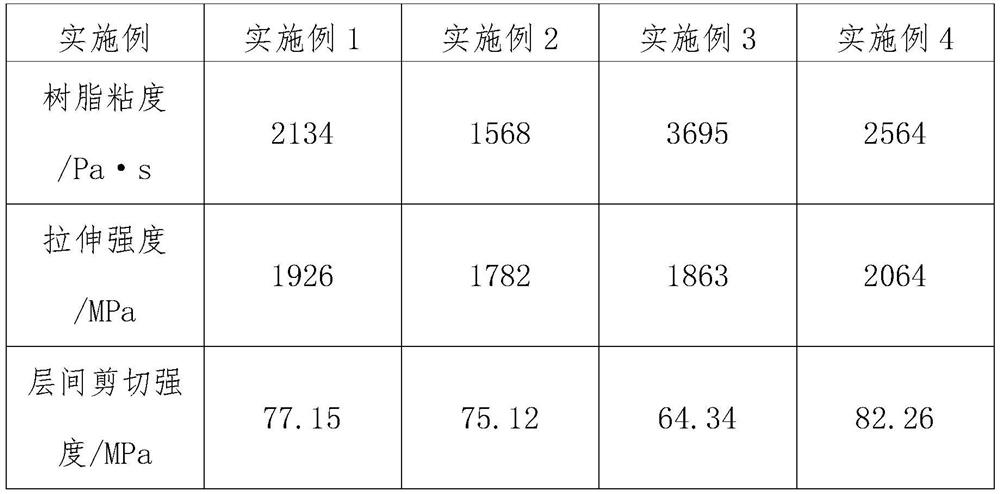

Examples

preparation example Construction

[0040] The present invention provides a kind of preparation method of the modified phthalonitrile resin described in the first aspect of the present invention in second aspect, described preparation method comprises the steps:

[0041] (1) take phthalonitrile resin, co-curable toughening agent and curing agent;

[0042] (2) phthalonitrile resin is melted;

[0043] (3) adding the co-curable toughening agent into the molten phthalonitrile resin and stirring to obtain a blend;

[0044] (4) Lowering the temperature of the blend, adding the curing agent and stirring to obtain a modified phthalonitrile resin.

[0045] According to some preferred embodiments, the melting temperature of the phthalonitrile resin is 100°C to 160°C;

[0046] In step (2), the phthalonitrile is melted to a homogeneous liquid.

[0047] According to some preferred embodiments, in step (3), the stirring time is 20-30 minutes.

[0048] According to some preferred embodiments, in step (4), the temperature o...

Embodiment 1

[0059] Formula is as follows (mass parts):

[0060] Phthalonitrile resin (resorcinol type phthalonitrile) 85

[0061] Co-curable toughener (containing phthalonitrile-terminated polyethersulfone) 10

[0062] Curing agent (diaminodiphenyl sulfone) 5

[0063] Wherein, the molar mass of the polyethersulfone end-capped with phthalonitrile is 2000 g / mol, and the number of functional groups containing phthalonitrile is 2;

[0064] The preparation method is as follows:

[0065] (1) Weighing resorcinol-type phthalonitrile, polyethersulfone and diaminodiphenylsulfone containing phthalonitrile-terminated polyethersulfone according to the ratio of parts by mass of 85:10:5;

[0066] (2) Melting resorcinol-type phthalonitrile to a homogeneous liquid at 150°C;

[0067] (3) Add polyethersulfone containing phthalonitrile-terminated polyethersulfone into the molten phthalonitrile resin, and stir for 30 minutes using a stirring device;

[0068] (4) Lower the temperature of the blend obtaine...

Embodiment 2

[0071] Formula is as follows (mass parts):

[0072] Phthalonitrile resin (bisphenol A phthalonitrile) 85

[0073] Co-curable toughener (containing phthalonitrile-terminated polyethersulfone) 10

[0074] Curing agent (diaminodiphenyl sulfone) 5

[0075] Wherein, the molar mass of the polyethersulfone end-capped with phthalonitrile is 2000g / mol, and the number of functional groups containing phthalonitrile is 2;

[0076] The preparation method is as follows:

[0077] (1) Weigh a certain amount of bisphenol A dicyanonitrile resin, polyethersulfone and diaminodiphenylsulfone containing phthalonitrile-terminated polyethersulfone according to the ratio of 85:10:5;

[0078] (2) Under the condition of 160°C, melt bisphenol A phthalonitrile to a homogeneous liquid;

[0079] (3) Add polyethersulfone containing phthalonitrile-terminated polyethersulfone into the molten phthalonitrile resin, and stir for 30 minutes using a stirring device;

[0080] (4) Lower the temperature of the bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molar mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com