A CNC machine tool with automatic chip removal function

A technology of CNC machine tools and chip removal machines, which is applied in the direction of manufacturing tools, metal processing machinery parts, metal processing equipment, etc., can solve problems such as cleaning difficulties, iron filings splashing around, and affecting the efficiency of workpiece processing, so as to reduce soil acidity, Easy to clean and prevent rust and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

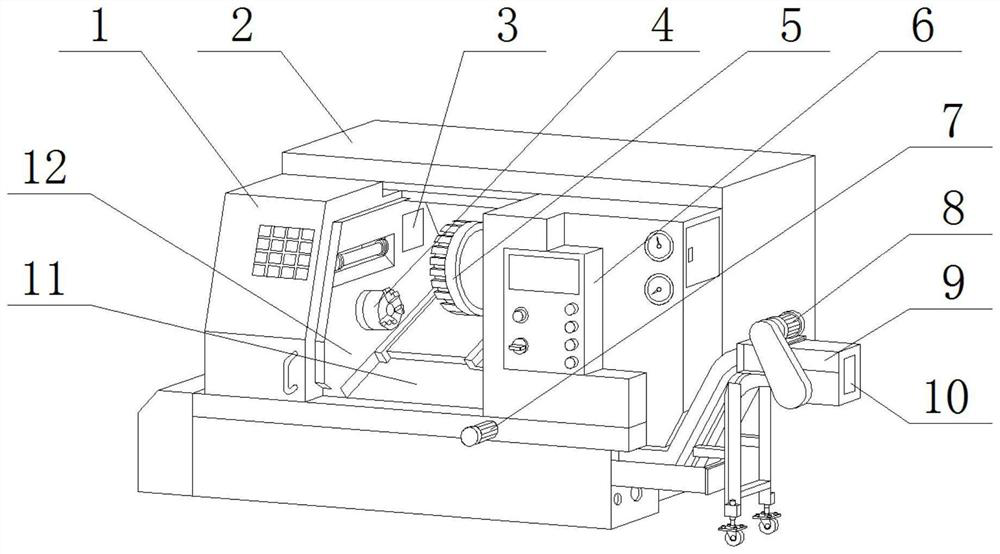

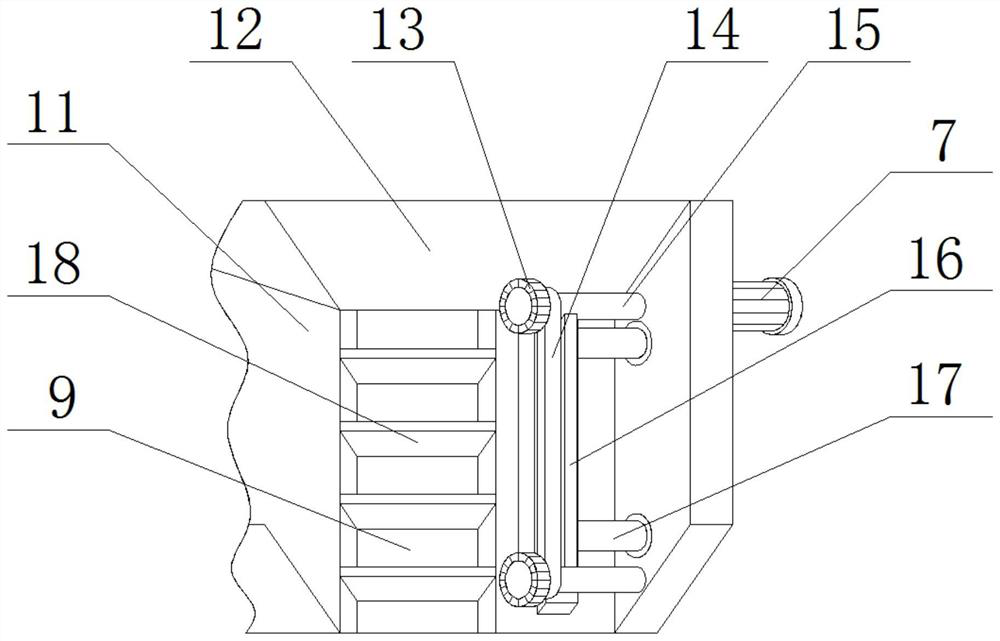

[0030] see Figure 1-Figure 3, the present invention provides a CNC machine tool with automatic chip removal function; comprising a CNC machine tool shell 2, a working room 12 is provided at the inner middle position of the CNC machine tool shell 2, and an absorption box 3 is movably installed above the left end of the working room 12 , a chuck 4 is fixedly installed under the left end of the working room 12, a chip plate 11 is welded and installed under the right side of the chuck 4, a fixed disk 5 is movably installed at the right end of the working room 12, and the left side of the front surface of the outer shell of the CNC machine tool 2 A numerically controlled machine tool door cover 1 is installed movable, a control box 6 is fixedly installed on the right side of the front surface of the numerically controlled machine tool shell body 2, a first motor 7 is fixedly mounted below the control box 6, and a row The chip machine shell 9, the second motor 8 is fixedly installe...

Embodiment 2

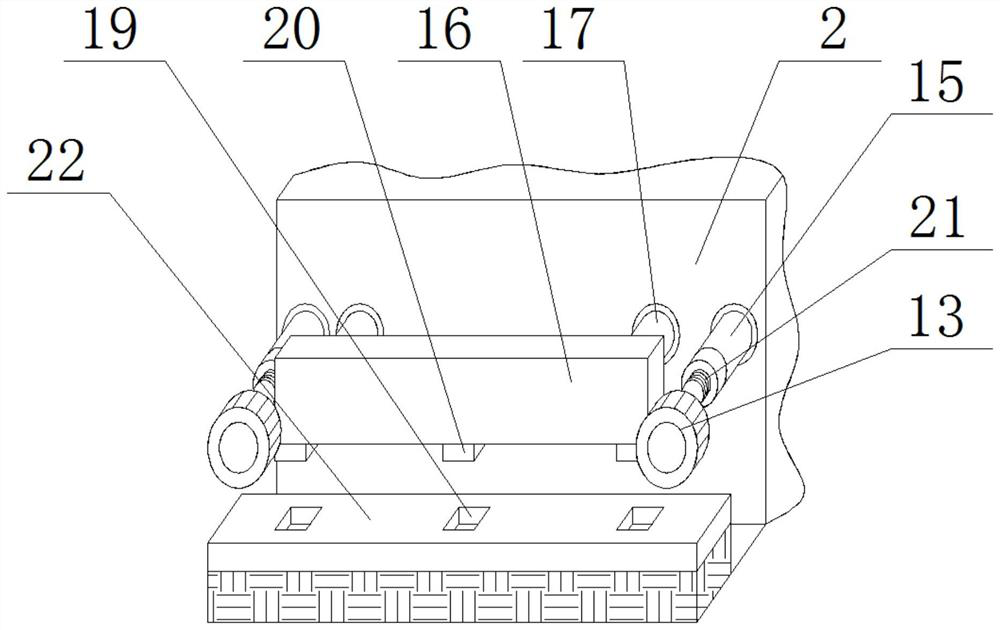

[0034] see Figure 4 , the stirring blades 25 are provided with several groups, and several groups of stirring blades 25 are uniformly welded and fixed on the outer surface of the rotating shaft 24, the rotating shaft 24 and the absorption box 3 are connected through the rotating shaft rotation, and the rotating shaft 24 is driven by a motor to rotate at a low speed; The storage port 23 is opened on the outer casing 2 of the CNC machine tool inside the working room 12. Two groups of sliders 26 and chutes 28 are respectively arranged. The two groups of sliders 26 are welded and fixed on the left and right sides of the absorption box 3 respectively. 28 are respectively fixed on the left and right sides of the inner surface of the storage opening 23 by screws, and the handle 27 and the absorption box 3 are fixedly connected by screws.

[0035] In this embodiment, the absorption box 3 that can slide in the storage port 23 is provided, and the rotation shaft 24 rotated by the motor...

Embodiment 3

[0037] see Figure 5 and Figure 6 , the mounting hole 33 is provided inside the left end of the chuck 4, the limit block 29, the fixing hole 36 and the spring 37 are respectively provided with four groups, and the four groups of fixing holes 36 are evenly opened in the inside of the rotating disk 30, and one end of the four groups of springs 37 is welded Be fixed on the bottom of four groups of fixing holes 36, the other end of four groups of springs 37 is welded and fixed on the bottom of four groups of limiting blocks 29, and four groups of limiting blocks 29 are all placed in the inside of four groups of fixing holes 36; The main shafts 35 are fixedly connected by screws, and there are several groups of mounting holes 33, and several groups of mounting holes 33 are evenly opened on the chuck 4 and the rotating disk 30, so that the screws can be fixed in the mounting holes 33, so that the chuck 4 is fixed on the On the turntable 30, a first limiting hole 34 is provided at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com