Industrial purification method of plasmid DNA and plasmid DNA

A purification method and plasmid technology, applied in the field of biopharmaceuticals, can solve the problems of removal, the total recovery rate of the plasmid and the control effect of endotoxin content, the restriction of industrial purification of plasmid DNA, the impact of operators and the environment, etc., to meet the needs of the industrial industry. Chemical purification production requirements, reduce the impact of operators and the environment, the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1 Industrial purification of DNA containing the new crown N protein particle

[0044] This example shows an industrial purification method for DNA containing the new crown N protein, which specifically includes the following steps:

[0045] (11) 2000g of Escherichia coli wet bacteria containing the new crown N protein DNA, lysed and neutralized according to the method described in the molecular cloning guide to obtain a mixture;

[0046] (12) After preliminary clarification of the above mixed solution with a tubular centrifuge, continue to filter with a combination of 5.0 μm and 0.5 μm filter elements, and rinse the filter element with purified water to obtain 58.5 L of alkali cracking filter clarification liquid;

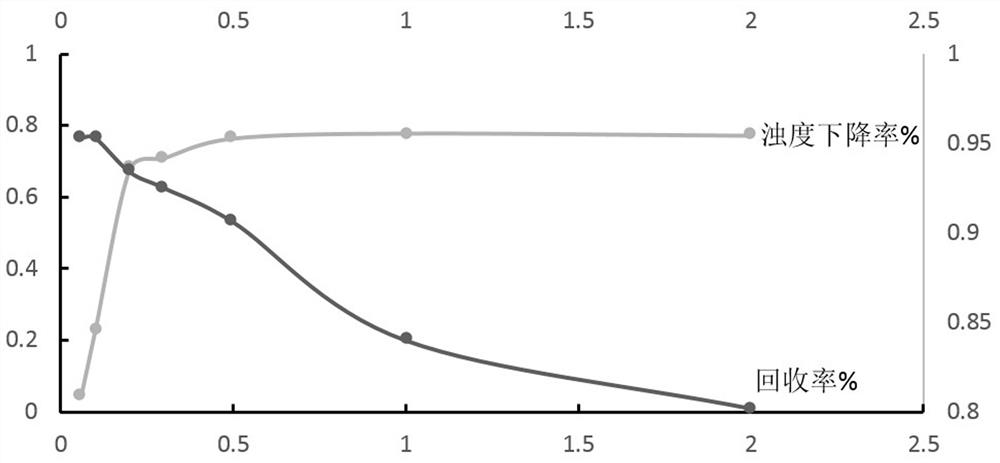

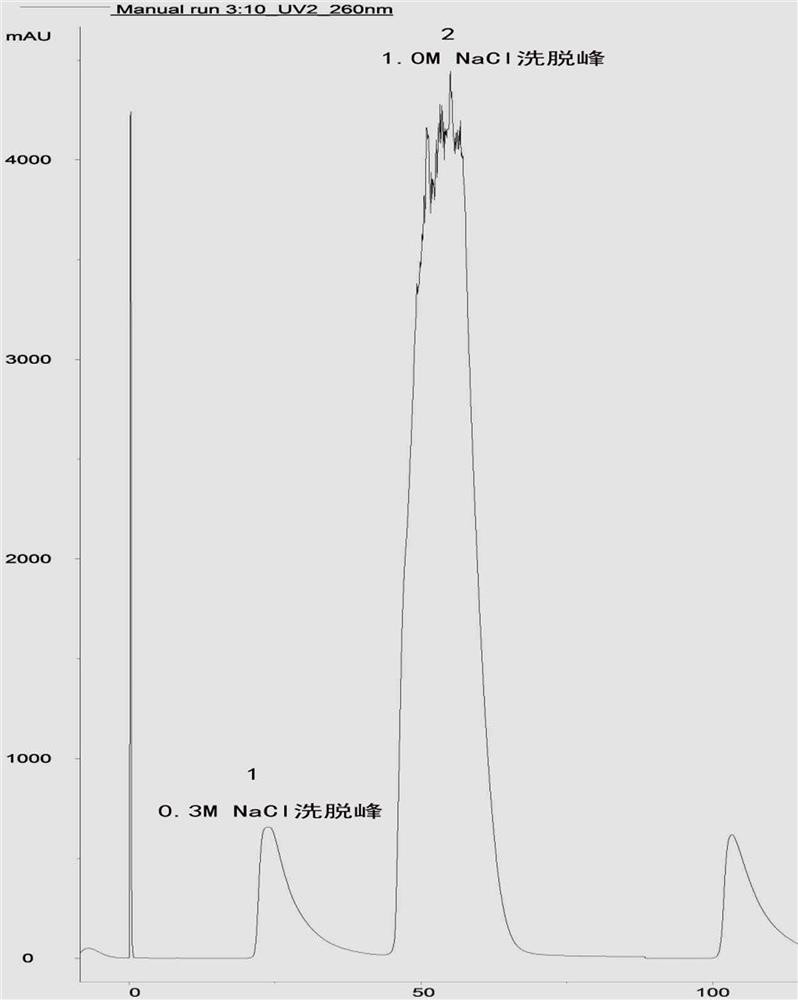

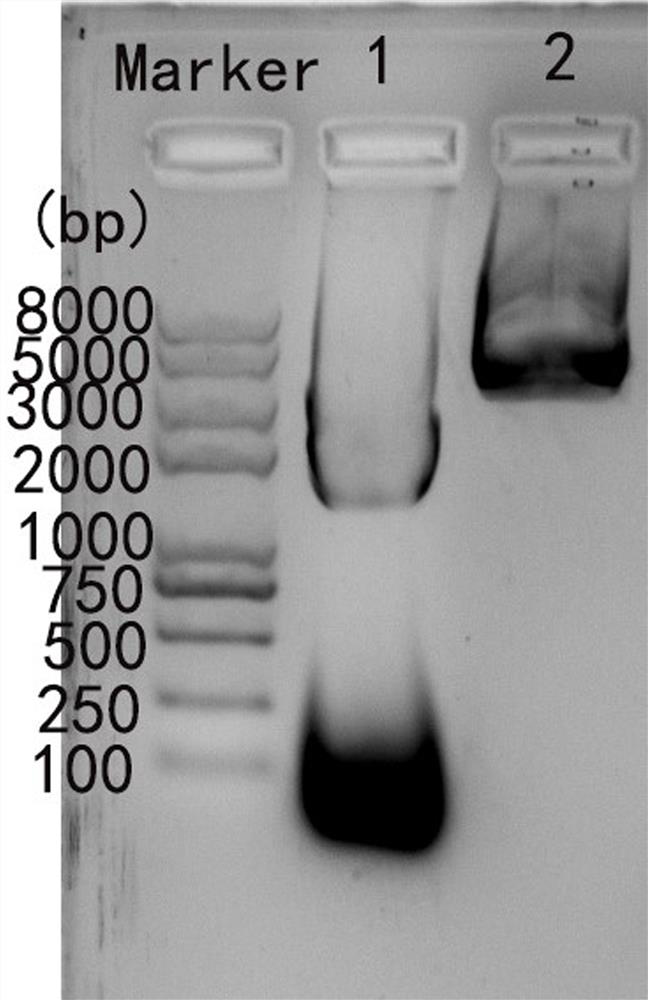

[0047] (13) Use an ultrafiltration membrane bag with a pore size of 300KD to perform ultrafiltration and concentration on the alkali lysis filtered clarified liquid, and then use 10mmol / L trishydroxyaminomethane, 1mmol / L disodium edetate, pH8.0 The bu...

Embodiment 2

[0053] Example 2 Industrial purification of DNA containing the new crown S protein particle

[0054] This example shows a method for industrial purification of particle DNA containing the new crown S protein, which specifically includes the following steps:

[0055] (21) 2000g of Escherichia coli wet bacteria containing the new crown S protein particle DNA, the mixed solution of lysing and neutralizing according to the method described in the molecular cloning guide;

[0056] (22) After preliminary clarification with a tubular centrifuge, continue to filter with a combination of 5.0 μm and 0.5 μm filter elements, and rinse the filter element with purified water to obtain 59 L of alkali cracking filter clarification liquid;

[0057] (23) Use an ultrafiltration membrane bag with a pore size of 300KD to concentrate the clarified solution of the alkali lysis filter, and then use a buffer containing 10mmol / L trishydroxyaminomethane, 1mmol / L disodium edetate, and pH8.0 The liquid w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com