Fermentation medium and fermentation method of human recombinant neutrophil inhibitory factor and hirulog hybrid

A technology of inhibitory factor and fermentation method, applied in the field of microbial fermentation, can solve the problems of low TNHH fermentation density, high acetic acid production, and high plasmid loss rate, and achieve good industrial application prospects, low acetic acid production, and low plasmid loss rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

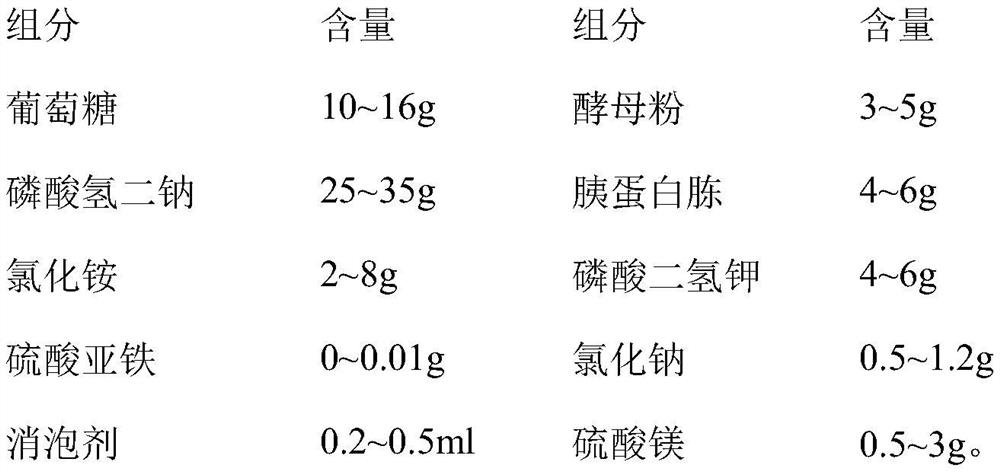

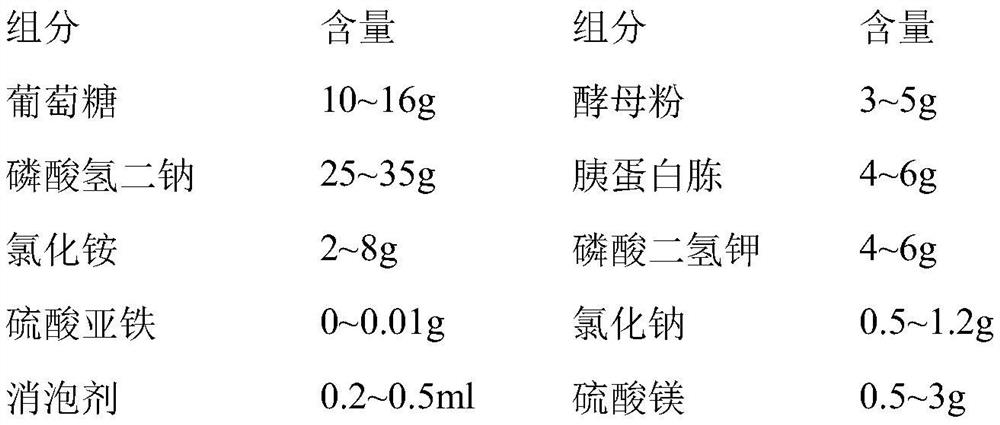

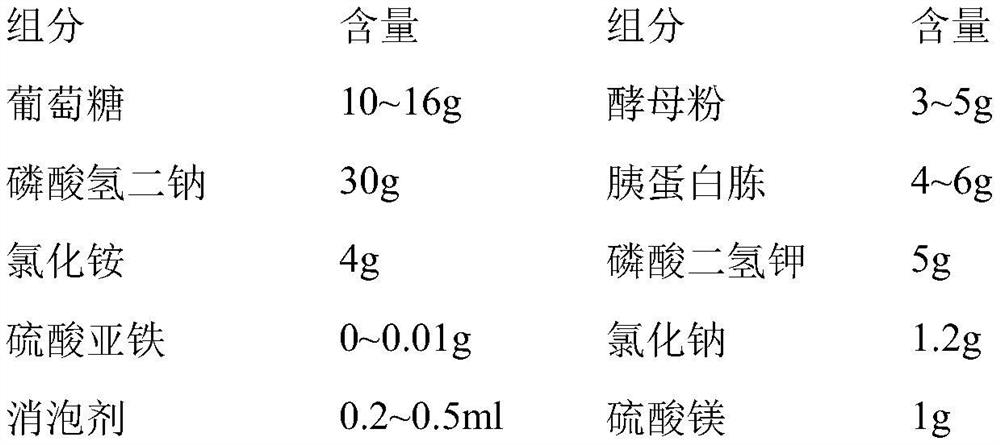

Method used

Image

Examples

Embodiment 1

[0067](1) Preparation of seed fluid:

[0068]Solid seed medium: yeast powder 5 g / l, protein 胨 10g / L, sodium chloride 10g / L, agarose 20g / L.

[0069]Liquid seed medium: yeast powder 5 g / l, protein 胨 10g / L, sodium chloride 10g / L.

[0070]A, Screening of strains: Take the bacteria PET-TNHH / BL21 (DE3) PLYSS, to LB flat line activation, 37 ° C culture overnight, picking up single collapse from plate to 8 mLB liquid test tube, 37 ° C, 180R / MIN Culture to OD600It was 1.0-1.5, and IPTG was added to a concentration of 0.2 mmol / L. After 4 hours, centrifugation was collected, and the SDS-PAGE electrophoresis was analyzed, and the TnHH single colonies were screened, and the higheststade of the row line plate was selected from 37 ° C to cultivate overnight. Save at 4 ° C after completion;

[0071]B, first-level seed liquid culture: from the retracted trained plate to pick up the single collaboration in a liquid test tube, 37 ° C, 150R / min culture for 15 h to OD600It is 0.5-1.0, as a see...

Embodiment 2

[0083](1) Preparation of seed fluid:

[0084]Solid seed medium: yeast powder 5 g / l, protein 胨 10g / L, sodium chloride 10g / L, agarose 20g / L.

[0085]Liquid seed medium: yeast powder 5 g / l, protein 胨 10g / L, sodium chloride 10g / L.

[0086]A, Screening of strains: Take the bacteria PET-TNHH / BL21 (DE3) PLYSS, to LB flat line activation, 37 ° C culture overnight, picking up single collapse from plate to 8 mLB liquid test tube, 37 ° C, 180R / MIN Culture to OD600It was 1.0-1.5, and IPTG was added to a concentration of 0.2 mmol / L. After 4 hours, centrifugation was collected, and the SDS-PAGE electrophoresis was analyzed, and the TnHH single colonies were screened, and the higheststade of the row line plate was selected from 37 ° C to cultivate overnight. Save at 4 ° C after completion;

[0087]B, first-level seed fluid culture: from the retracted trained flattening of single collapse into a liquid test tube, 33 ° C, 150R / min culture to OD loading with 8 ml seed medium600It is 0.5-1.0...

Embodiment 3

[0098](1) Preparation of seed fluid:

[0099]Solid seed medium: yeast powder 5 g / l, protein 胨 10g / L, sodium chloride 10g / L, agarose 20g / L.

[0100]Liquid seed medium: yeast powder 5 g / l, protein 胨 10g / L, sodium chloride 10g / L.

[0101]A, Screening of strains: Take the bacteria PET-TNHH / BL21 (DE3) PLYSS, to LB flat line activation, 37 ° C culture overnight, picking up single collapse from plate to 8 mLB liquid test tube, 37 ° C, 180R / MIN Culture to OD600It was 1.0-1.5, and IPTG was added to a concentration of 0.2 mmol / L. After 4 hours, centrifugation was collected, and the SDS-PAGE electrophoresis was analyzed, and the TnHH single colonies were screened, and the higheststade of the row line plate was selected from 37 ° C to cultivate overnight. Save at 4 ° C after completion;

[0102]B, primary seed fluid culture: from the retracted culture of flattened single collapse into a liquid test tube equipped with 8 ml seed medium, 35 ° C, 150R / min culture 12 h to OD600It is 0.5-1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com