A method for demagnetizing metal impurity particles on the surface of lithium battery electrode sheets

A surface metal and electrode sheet technology, which is applied in the field of demagnetization of metal impurity particles on the surface of lithium battery electrode sheets, can solve the problems of battery short circuit, aggravated self-discharge, large self-discharge, etc., to reduce self-discharge, improve quality and consistency , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

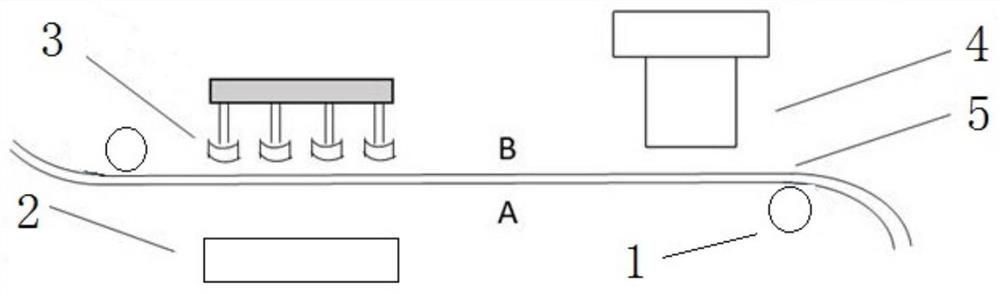

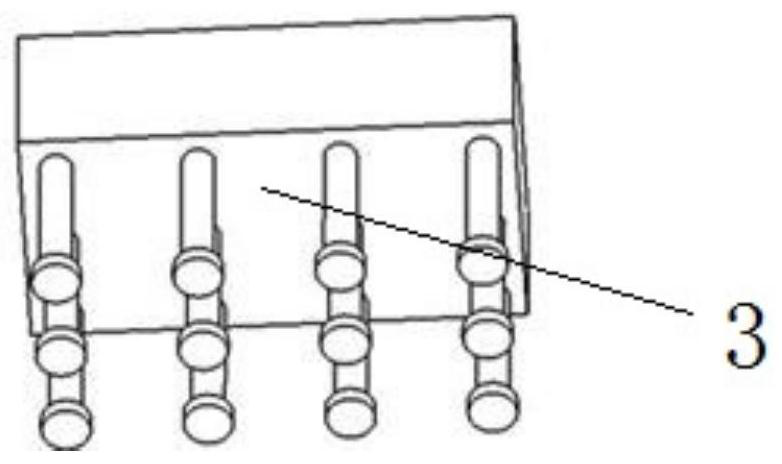

[0034] see figure 1 , the magnetic field transmitter is 30mm away from the A side of the electrode sheet, and the magnetic field transmitter of the permanent magnet is used to generate a 6000GS magnetic field to act on the A side of the electrode sheet. There are 3 rows, and the distance between the probe and the surface B of the electrode sheet is 2mm.

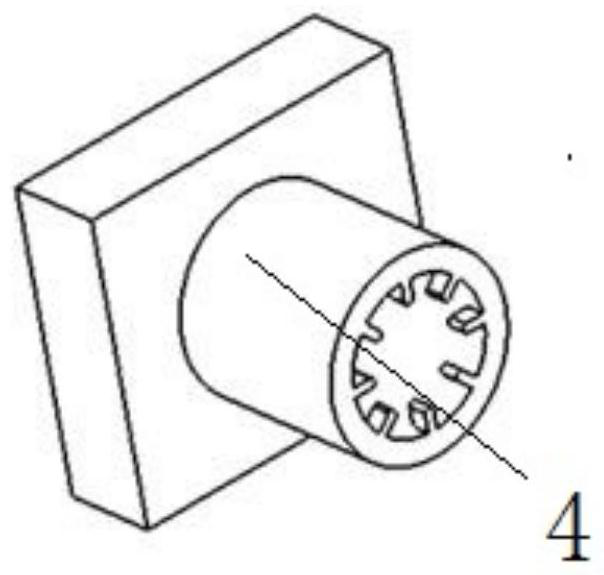

[0035] During the detection process of electrode sheet movement, the Hall sensor detects that the magnetic size in the grid surrounded by (2,3)(2,4)(3,3)(3,4) coordinate points is 11GS, and this area The surrounding magnetic size is 1.8GS. When the electrode sheet in this area is transported to the adsorption demagnetization system, the closed cover will seal the grid, and the air blowing part will blow out compressed air from the air outlet to blow the magnetic metal impurity particles in the grid. At the same time, the adsorption part above generates negative pressure, so as to absorb and remove the magnetic metal impurity...

Embodiment 2

[0037]The magnetic field transmitter is 20mm away from the A side of the electrode sheet. The magnetic field transmitter of the electromagnetic coil generates a magnetic field of 8000GS to act on the A side of the electrode sheet. The distance between the probe and the surface B of the electrode sheet is 6mm.

[0038] During the detection process of the electrode sheet movement, the Hall sensor detects that the magnetic size in the two grids surrounded by (2,1)(2,2)(4,1)(4,2) coordinate points is 13GS, while The magnetic field around this area is 2.5GS. When the electrode sheet in this area is transported to the adsorption demagnetization system, the closed cover is first surrounded by (3,1)(3,2)(4,1)(4,2) coordinate points The formed grid is closed, the blowing part blows air, and the adsorption part absorbs; then the closed cover rises and moves to the grid formed by (2,1)(2,2)(3,1)(3,2) coordinate points The grids are sealed, and then blown and adsorbed, thus completing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com