TiO2-doped Co composite photocatalyst, preparation method thereof and application of TiO2-doped Co composite photocatalyst in treatment of phenolic wastewater

A composite light and catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of low efficiency in degradation of organic matter, and achieve uniform and stable chemical composition , good catalytic effect, environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] TiO 2 Doped Co composite photocatalyst, preparation method comprises the steps:

[0030] 1. Slowly drop 10ml of tetrabutyl titanate into 40ml of absolute ethanol, stir vigorously at room temperature for 40min to obtain a light yellow liquid.

[0031] 2. Take 10ml of absolute ethanol, 5ml of glacial acetic acid, 5ml of concentrated nitric acid and 5ml of cobalt nitrate aqueous solution with a concentration of 0.4mol / L, and stir evenly to obtain a light red solution.

[0032] 3. Add the light red solution obtained in step 2 to the light yellow liquid obtained in step 1 dropwise, stir for 1 hour, let it settle at room temperature for 48 hours, and filter to collect the solid.

[0033] 4. Wash the solid matter obtained in step 3 with ultrapure water and absolute ethanol, and put it into an oven at 110° C. to dry to obtain solid particles.

[0034] 5. Put the solid particles obtained in step 4 into a mortar and grind them into powder, then move them to a crucible, put them...

Embodiment 2

[0035] Example 2 TiO 2 Application of Co-doped Composite Photocatalyst in Catalytic Degradation of Nonylphenol

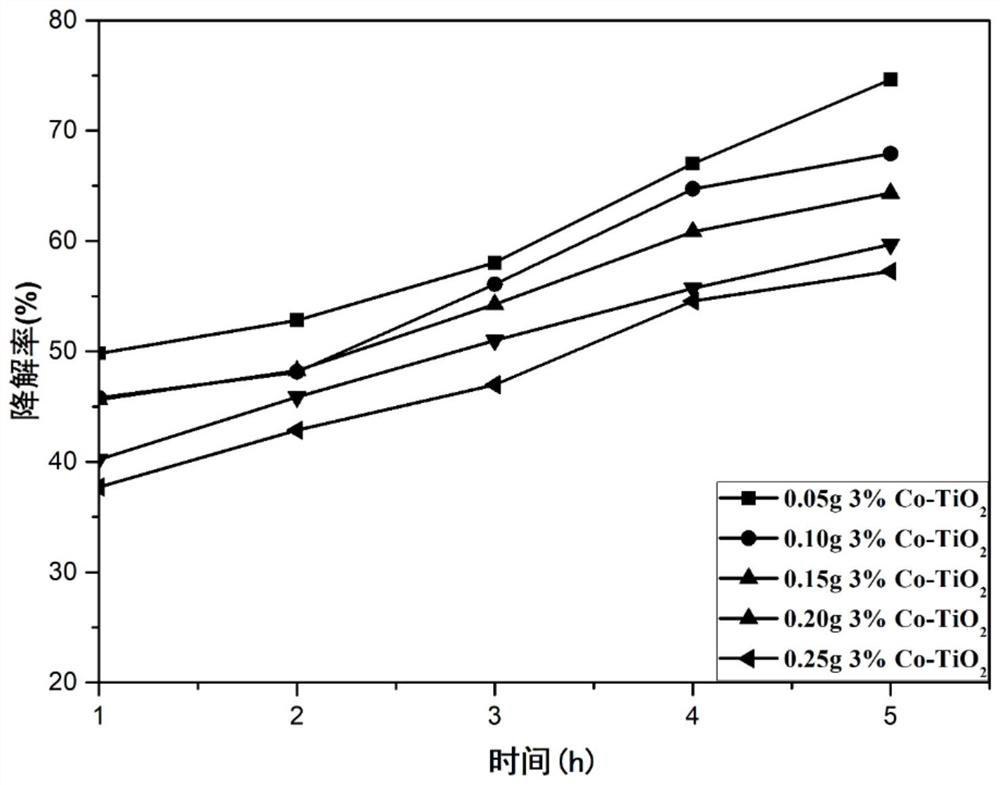

[0036] The method is as follows: In the solution containing nonylphenol, adjust the initial concentration of nonylphenol to 15-25mg / L, add TiO 2 Doped Co composite photocatalyst, photocatalytic degradation for 300min. Add 0.05-0.25g of TiO to every 100mL of nonylphenol solution with an initial concentration of 15-25mg / L 2 Doped Co composite photocatalyst.

[0037] The degradation rate of nonylphenol solution can be calculated by the following formula:

[0038] Q=(C 0 -C t ) / C 0 ×100%

[0039] Among them, Q is the degradation rate of nonylphenol solution, C 0 is the initial concentration of nonylphenol solution, C t For adding TiO 2 Concentration of nonylphenol solution at time t after doping Co composite photocatalyst.

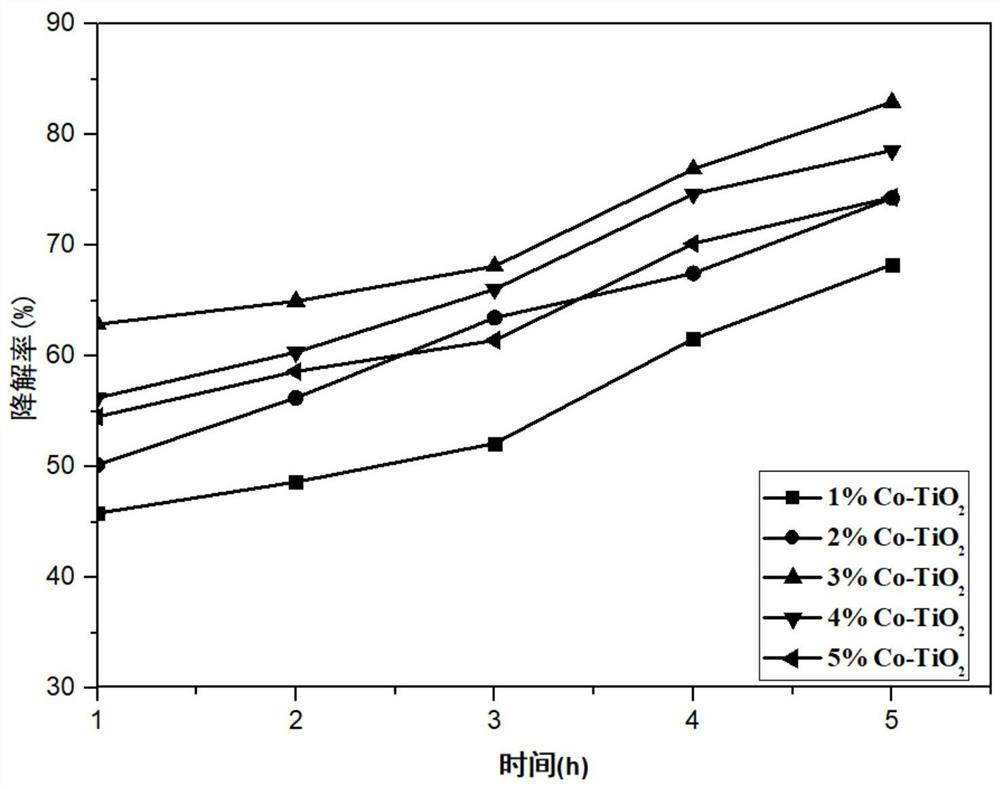

[0040] (1) TiO prepared with different Co doping amounts 2 Effect of Co-doped Composite Photocatalyst on Catalytic Degradation of Nonyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com