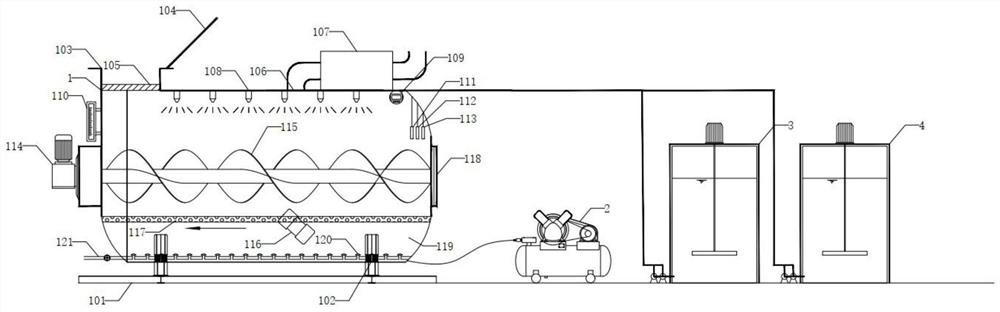

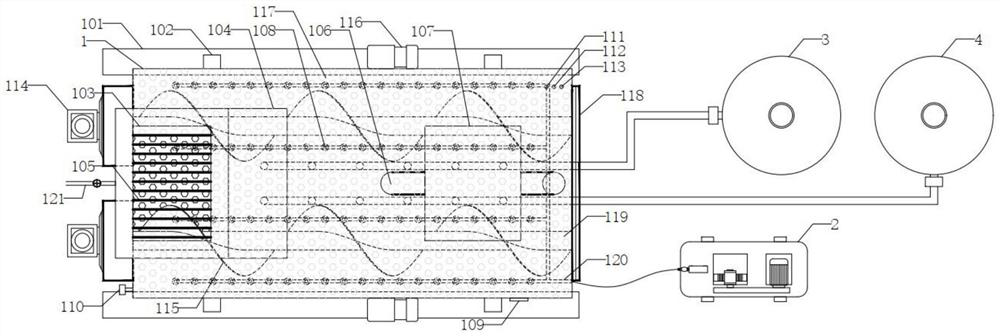

Spiral stirring type bioreactor and method for repairing soil with organic contamination

A bioreactor and screw stirring technology is applied in the field of bioremediation of organic polluted soil, which can solve the problems of limited remediation efficiency, complex process and high cost, and achieve the effects of high solid-liquid separation efficiency, improved treatment efficiency and improved environmental conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] When dealing with PCB-contaminated soil, put 4m into the tank through the feed port 3 Contaminate the soil, and at the same time, the liquid spraying device sprays biosurfactant with a concentration of 4% (v / v) according to the liquid-solid ratio of 3:1, dilutes the contaminated soil to a certain concentration of mud, and adjusts the pH to 6.5. Turn on the left and right spiral stirring device and aeration device, control the stirring speed to 150r / min, the mud temperature to 30°C, and the air velocity to 0.5m 3 / h. Stir for 10 minutes to make the surfactant fully contact with the soil, promote the transfer of pollutants to the liquid phase, and prepare for the efficient and rapid degradation of pollutants. Turn on the liquid spray device and press 5.5×10 7 Bacteria solution / kg soil is added to the bacterial solution, and the volume and mass of the bacterial solution is 1L / m 3 Soil, nutrients in the bacterial solution C:N:P=100:10:1. Stirring and aeration are contin...

Embodiment 2

[0033] When treating phthalate-contaminated soil, put 4m into the tank 3 To pollute the soil, spray the biosurfactant with a concentration of 1% (v / v) according to the liquid-solid ratio of 2:1 at the same time, dilute the contaminated soil to a certain concentration of mud, and adjust the pH to 7.1. Turn on the left and right spiral stirring device and aeration device, control the stirring speed to 100r / min, the mud temperature to 25°C, and the air velocity to 0.1m 3 / h. Stir for 5 minutes to make the surfactant fully contact with the soil and promote the transfer of pollutants to the liquid phase. Turn on the liquid spray device Press 3×10 7 Bacteria solution / kg soil is added to the bacterial solution, and the volume and mass of the bacterial solution is 0.5L / m 3 Soil, nutrients in the bacterial solution C:N:P=100:10:1. Stirring and aeration are continued at the same time, and the online monitoring system is used to observe the pH, temperature, and oxygen content indicat...

Embodiment 3

[0035] When dealing with petroleum hydrocarbons and polycyclic aromatic hydrocarbons compound polluted soil, put 4m into the tank 3 To pollute the soil, spray the biosurfactant with a concentration of 2% (v / v) according to the liquid-solid ratio of 3:1 at the same time, dilute the contaminated soil to a certain concentration of mud, and adjust the pH to 7.5. Turn on the left and right spiral stirring device and aeration device, control the stirring speed to 120r / min, the mud temperature to 28°C, and the air velocity to 0.3m 3 / h. Stir for 10 minutes to make the surfactant fully contact with the soil and promote the transfer of pollutants to the liquid phase. Turn on the liquid spraying device and add the bacterial liquid at 4×107 strains / kg of soil, the added volume and mass of the bacterial liquid is 0.8L / m3 soil, and the nutrients in the bacterial liquid are C:N:P=100:10:1. Stirring and aeration are continued at the same time, and the online monitoring system is used to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com