Preparation method of nuclear-grade pure uranium tetrafluoride

A pure uranium tetrafluoride, nuclear-grade technology, applied in the field of nuclear-grade pure uranium tetrafluoride preparation, can solve the problems of long process flow, large amount of waste water, high energy consumption, etc., and achieve the effect of cost reduction and environmental protection preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

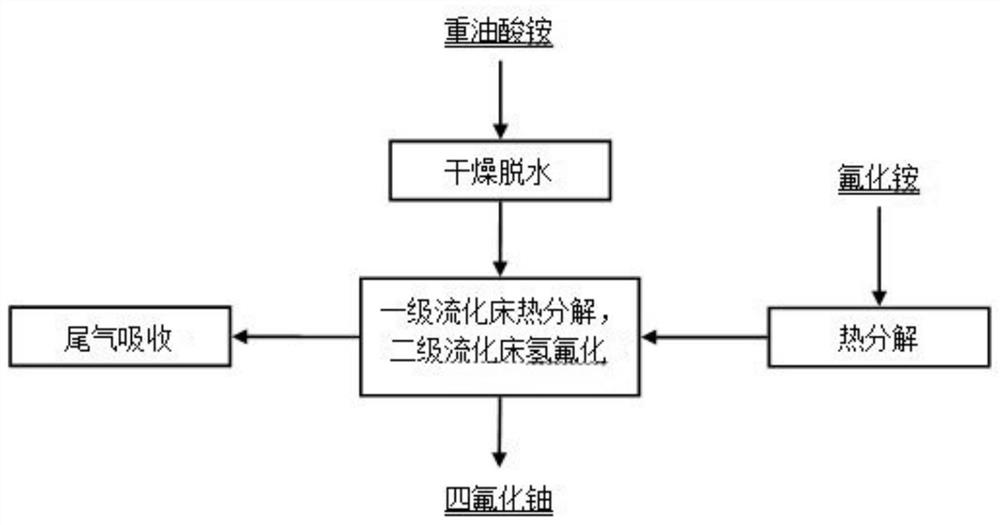

[0022] A method for preparing nuclear-grade pure uranium tetrafluoride, comprising the steps of:

[0023] Step 1, ammonium diuranate pretreatment

[0024] Add ammonium diuranate to a microwave dryer for drying.

[0025] Step two, ammonium fluoride pretreatment

[0026] Ammonium fluoride is added to the reaction kettle, and it is thermally decomposed under high temperature conditions to produce a mixed gas of hydrogen fluoride and ammonia. preprocessing.

[0027] Step 3: Fluidized bed preparation of UF4

[0028] The ammonium diuranate pretreated in step one and the mixed gas of hydrogen fluoride and ammonia pretreated in step two are prepared in a bipolar series countercurrent fluidized bed to produce uranium tetrafluoride (the product quality meets the EJ / T990-96 standard), Exhaust gas enters the exhaust gas absorption system.

[0029] The moisture in the ammonium diuranate described in the first step is 200 mesh.

[0030] The decomposition temperature of the ammonium fl...

Embodiment 1

[0033] Add 450kg of ammonium diuranate to a microwave dryer for drying, and then add it to a fluidized bed silo after drying. Add hydrogen fluoride into the reactor, the temperature of the reactor is 130°C, and the pressure is 0.40Mpa. The pressure in the buffer tank is 0.30Mpa, and the temperature of the gas heater is 460°C.

[0034] The temperature of the primary fluidized bed is 480°C, the pressure is 80kpa, and the intake volume of the mixed gas of hydrogen fluoride and ammonia is 47m 3 / h. The temperature of the intermediate hopper is 370°C and the pressure is 16kpa. The temperature of the secondary fluidized bed is 430°C, the pressure is 120kpa, and the intake volume of the mixed gas of hydrogen fluoride and ammonia is 55m 3 / h.

Embodiment 2

[0036] Add 400kg of ammonium diuranate into a microwave dryer for drying, and then add it to a fluidized bed silo after drying. Add hydrogen fluoride into the reactor, the temperature of the reactor is 150°C, and the pressure is 0.45Mpa. The pressure in the buffer tank is 0.35Mpa, and the temperature of the gas heater is 480°C.

[0037] The temperature of the primary fluidized bed is 490°C, the pressure is 90kpa, and the intake volume of the mixed gas of hydrogen fluoride and ammonia is 49m 3 / h. The temperature of the intermediate hopper is 375°C and the pressure is 16kpa. The temperature of the secondary fluidized bed is 420°C, the pressure is 110kpa, and the intake volume of the mixed gas of hydrogen fluoride and ammonia is 50m 3 / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com