Preparation method and application of isoleucine chelated metal

A technology of isoleucine and metals, which is applied in the field of preparation of amino acid chelates, can solve the problems that cannot be applied to large-scale production of feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

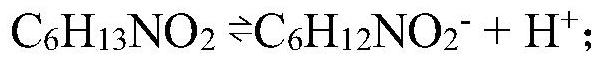

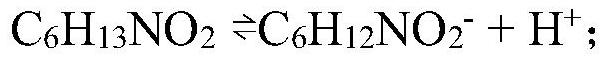

Method used

Image

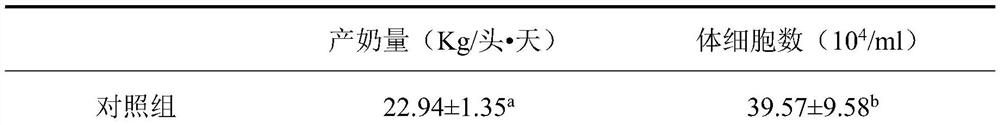

Examples

Embodiment 1

[0068] A method for preparing zinc isoleucine, comprising the following steps: start stirring, add 535.4Kg of isoleucine with a purity of 98% to 2.5t of water for dissolution, then raise the temperature to 50°C, slowly add 47% zinc Zinc chloride 278.3Kg, control the pH value to 5.5, react for 2.5 hours, after the reaction, cool the reaction system below 40°C, crystallize, separate by centrifugal filtration, wash with water 3 times, and dry in the oven to obtain zinc isoleucine 604.8 Kg.

[0069] In this embodiment, the measured isoleucine content in zinc isoleucine products is 77.0%, Zn 2+ It is 19.3%, the water loss rate at 104°C is 3.6%, that is, the purity is 96.3%, and the yield is 89.4% based on isoleucine, that is, the molar ratio of isoleucine to zinc is about 2:1, and the molecular formula is Zn(C 6 h 12 NO 2 ) 2 .

Embodiment 2

[0071] A method for preparing manganese isoleucine, comprising the following steps: start stirring, add 2.7 tons of isoleucine hydrochloride aqueous solution with a concentration of 25% into the reaction kettle, heat up to 85°C, slowly add manganese content of 31 % manganese sulfate monohydrate 354Kg, after adding 100L glycerol, control the pH value to 6.0, react for 2.5h, after the reaction, cool the reaction system to below 40°C, wash with water 3 times after separation by centrifugal filtration, and dry in the oven. 643Kg of manganese isoleucine was obtained.

[0072] In the present embodiment, it is measured that the isoleucine content in the isoleucine zinc product is 75.7%, Mn 2+ It is 16.0%, the water loss rate at 104°C is 8.2%, that is, the purity is 91.7%, and the yield is 93.5% based on isoleucine, that is, the molar ratio of isoleucine to manganese is about 2:1, and the molecular formula is Mn(C 6 h 12 NO 2 ) 2 .

Embodiment 3

[0074] A method for preparing zinc isoleucine, comprising the following steps: start stirring, add 2.7 tons of isoleucine hydrochloride aqueous solution with a concentration of 25% into the reaction kettle, add 185L of isopropanol, and heat up to 78°C , slowly add 226Kg of basic zinc chloride with a zinc content of 58%, control the pH value to 8.0, and react for 1.5h. After the reaction is completed, the reaction system is cooled to below 40°C to crystallize, centrifugally filtered and separated, washed with water for 3 times, and dried in a drying room Dry to obtain zinc isoleucine 609Kg.

[0075] In the present embodiment, it is measured that the isoleucine content in the isoleucine zinc product is 76.9%, Zn 2+ It is 19.3%, the water loss rate at 104°C is 3.8%, that is, the purity is 96.2%, and the yield is 89.9% based on isoleucine, that is, the molar ratio of isoleucine to zinc is about 2:1, and the molecular formula is Zn(C 6 h 12 NO 2 ) 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com