Thin-coating type high-corrosion-resistance impregnating coating as well as preparation method and application thereof

A dipping coating and corrosive technology, which is applied in the field of thin-coated high-corrosion-resistant dipping coatings and its preparation, can solve the problems of extended construction period, high construction cost, and low construction efficiency, and achieve extended construction time, low cost, and The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1, the preparation of thin coating type high anti-corrosion impregnation coating A-1

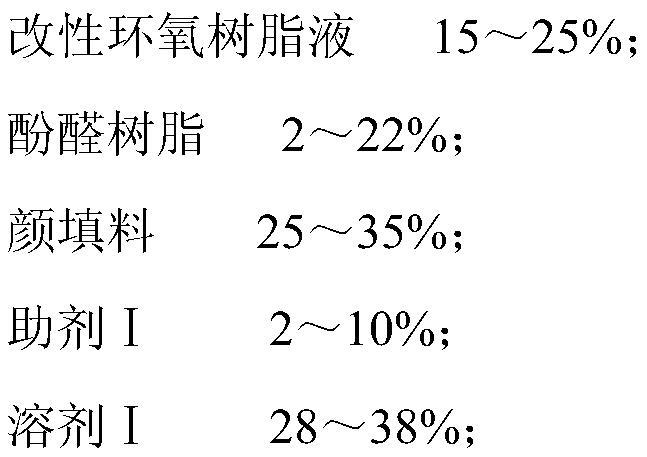

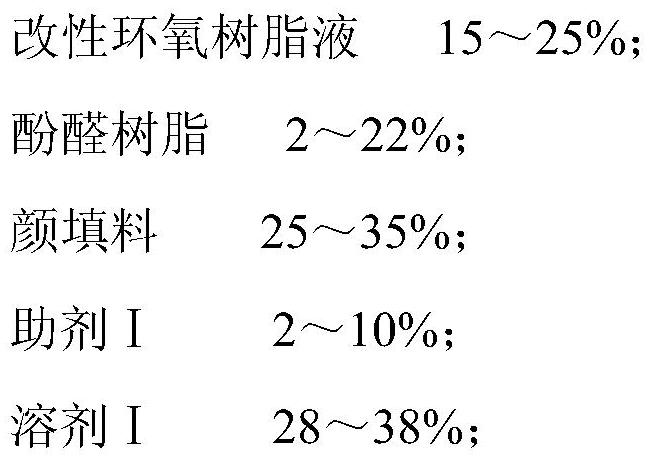

[0055] (1), the preparation of thin coating type high anti-corrosion impregnation paint A-1 comprises the following steps:

[0056] (1), preparation of modified epoxy resin liquid

[0057] Add 30kg cyclohexanone, 25kg methyl isobutyl ketone and 5kg methyl amyl ketone into the reaction kettle, start stirring, control the speed at 100-200 rpm, then slowly add 30kg 901 epoxy resin, and slowly heat up to 80°C, control the stirring speed at 300 rpm, keep warm until the 901 epoxy resin is completely dissolved, cool to 45°C ± 5°C, add 10kg epoxy modified silicone resin SMH-60, control the stirring speed at 300 rpm , until it is stirred into a uniform transparent liquid, the solid content is 36% (m / m), and the material is filtered and discharged with an 80 mesh sieve to obtain a modified epoxy resin liquid.

[0058] (2), preparation of component A

[0059] Add the modified epoxy...

Embodiment 2

[0072] Embodiment 2, the preparation of thin coating type high anti-corrosion impregnation coating A-2

[0073] (1), the preparation of thin coating type high anti-corrosion impregnation coating A-2 comprises the following steps:

[0074] (1), preparation of modified epoxy resin liquid

[0075] Add 20kg of cyclohexanone, 15kg of methyl isobutyl ketone and 7.5kg of methyl amyl ketone into the reaction kettle, start stirring, control the speed at 100-200 rpm, then slowly add 22.5kg of 904 epoxy resin, Slowly heat up to 98°C, stirring at 300 rpm, keep warm until 904 epoxy resin is completely dissolved, cool to 45°C ± 5°C, add 35kg SMH-30 epoxy modified silicone resin, stirring at 300 rpm until it is stirred into a uniform transparent liquid, the solid content is 40% (m / m), and the material is filtered and discharged with an 80 mesh sieve to obtain a modified epoxy resin liquid.

[0076] (2), preparation of component A

[0077] Add 22kg modified epoxy resin solution, 8kg phenol...

Embodiment 3

[0090] Embodiment 3, the preparation of thin coating type high anti-corrosion impregnation coating A-3

[0091] (1), the preparation of thin coating type high anti-corrosion impregnation paint A-3 comprises the following steps:

[0092] (1), preparation of modified epoxy resin liquid

[0093] Add 15kg cyclohexanone, 20kg methyl isobutyl ketone and 5kg methyl amyl ketone in the reactor, start stirring, control the rotating speed to be 100-200 rpm, then slowly add 20kg 909 epoxy resin, slowly Heat up to 140°C, control the stirring speed to 300 rpm, keep warm until the 909 epoxy resin is completely dissolved, cool to 45°C±5°C, add 40kg epoxy modified silicone resin SMH-30, and stir at 300 rpm until it is stirred into a uniform transparent liquid, the solid content is 40% (m / m), and the material is filtered and discharged with an 80 mesh sieve to obtain a modified epoxy resin liquid.

[0094] (2), preparation of component A

[0095] Add 25kg of the modified epoxy resin solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com