Polyacrylic acid synthetic thickener for reactive dye printing of viscose fabric and preparation method and application of polyacrylic acid synthetic thickener

A technology for synthesizing thickeners and reactive dyes, which can be used in dyeing, textiles, and papermaking. It can solve the problems of insufficient silicone modification and achieve high color fastness to soaping, small viscosity changes, and dry resistance. The effect of high color fastness to rubbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

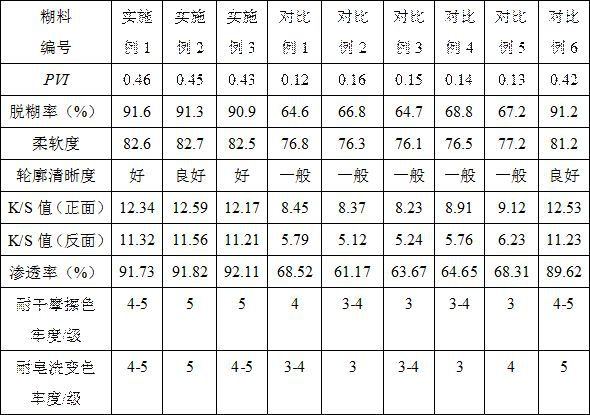

Examples

Embodiment 1

[0024] The preparation method of the polyacrylic acid synthetic thickener of viscose fabric reactive dye printing, concrete method comprises the steps:

[0025] (1) Dissolve 1mL of methacrylic acid and 15g of starch in 300mL of deionized water, adjust the pH of the reaction solution to 10.5 with lye, and stir for reaction. Branched starch modified solution.

[0026] (2) Dissolve 1mL of methacrylic acid, 150mL of the methacrylic acid grafted starch modification solution prepared in step (1) and 2mL of 3-methacrylic acid propyl tris(trimethoxysilane) in 100mL of deionized water at the same time to prepare Monomer solution, 1.25g of ammonium persulfate was dissolved in 85mL of deionized water and configured as an initiator solution for later use; then, under stirring conditions, the temperature was controlled at 80°C, and the configured monomer solution and ammonium persulfate initiator solution were separately Add dropwise into a four-necked flask filled with 100 mL of deionize...

Embodiment 2

[0030] The preparation method of the polyacrylic acid synthetic thickener of viscose fabric reactive dye printing, concrete method comprises the steps:

[0031] (1) Dissolve 1mL of methacrylic acid and 10g of starch in 200mL of deionized water, adjust the pH value of the reaction solution to 10 with lye, and stir for reaction. The reaction temperature is 79°C, and the reaction time is 2h. Branched starch modified solution.

[0032] (2) Dissolve 1mL of methacrylic acid, 100mL of methacrylic acid grafted starch modification solution prepared in step (1) and 1mL of 3-methacrylic acid propyl tris(trimethoxysilane) in 100mL of deionized water at the same time to prepare Monomer solution, 1g of ammonium persulfate dissolved in 50mL of deionized water is configured as an initiator solution for later use; then under stirring conditions, the temperature is controlled at 79°C, and the configured monomer solution and ammonium persulfate initiator solution are dripped separately Add it t...

Embodiment 3

[0036] The preparation method of the polyacrylic acid synthetic thickener of viscose fabric reactive dye printing, concrete method comprises the steps:

[0037] (1) Dissolve 1mL of methacrylic acid and 20g of starch in deionized water, adjust the pH of the reaction solution to 11 with lye, and stir for reaction. The reaction temperature is 81°C, and the reaction time is 4h to obtain methacrylic acid graft Starch modified liquid.

[0038] (2) Dissolve 1mL of methacrylic acid, 200mL of the methacrylic acid grafted starch modification solution prepared in step (1) and 3mL of 3-methacrylic acid propyl tris(trimethoxysilane) in 100mL of deionized water at the same time to prepare For the monomer solution, 1.5g of ammonium persulfate was dissolved in 75mL of deionized water and configured as an initiator solution for later use; then, under stirring conditions, the temperature was controlled at 81°C, and the configured monomer solution and ammonium persulfate initiator solution were ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com