All-fiber laser detection system for tunnel safety monitoring and working method

A technology of safety monitoring and laser detection, which is applied in the direction of measuring devices, optical devices, color/spectral characteristics measurement, etc., can solve the problems of low work efficiency, low detection accuracy, poor real-time performance, etc., and achieve simple structure, high measurement accuracy, The effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

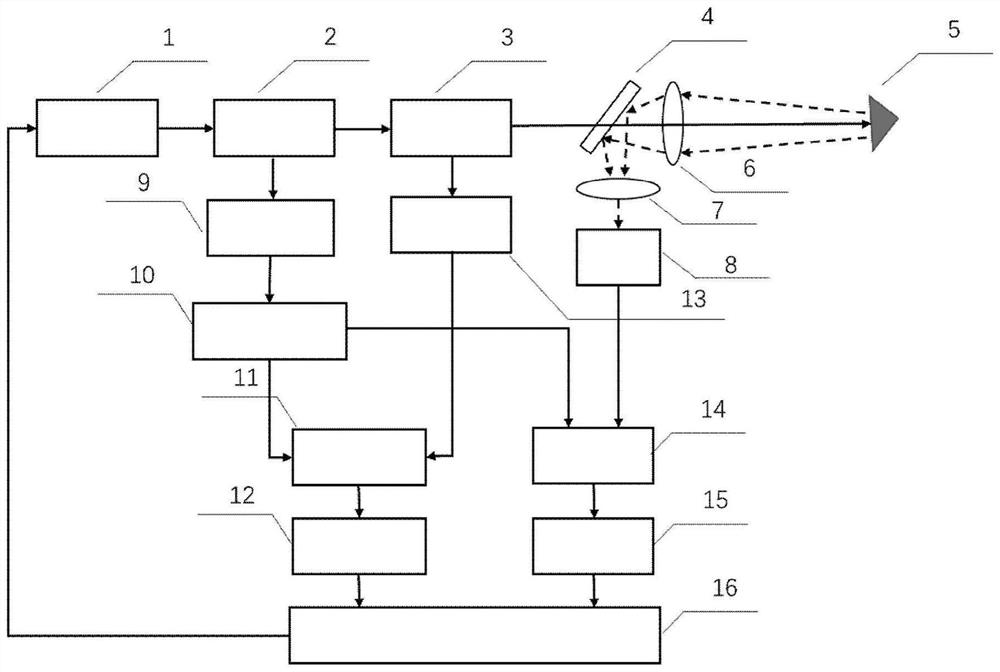

[0034] An all-fiber laser detection system for tunnel safety monitoring, including a laser, an optical fiber splitter 1 is arranged on the output optical path of the laser, and the two outputs of the optical fiber splitter 1 are respectively sent to the optical fiber splitter 2 and the fiber modulator, and the fiber modulation The output of the splitter is connected to the fiber splitter 3.

[0035] The two outputs of the fiber splitter 3 are respectively connected to the fiber combiner 1 and the fiber combiner 2 .

[0036] One output of the fiber splitter 2 is connected to the fiber combiner 1 through the fiber circulator, and the other output of the fiber splitter 2 is reflected by the mirror, then connected to the fiber combiner 2 through an aspheric lens and a fiber coupling head .

[0037] The optical fiber combiner 1 is connected to the data acquisition processing and control system through the photodetector 1 , and the optical fiber combiner 2 is connected to the data ...

Embodiment 2

[0039] An all-fiber laser detection system for tunnel safety monitoring, its structure is as described in Embodiment 1, the difference is that the optical fiber beam splitter 1 is a 90 / 10 optical fiber beam splitter, and the laser is split by the 90 / 10 optical fiber beam splitter It is the A path with 90% energy and the B path with 10% energy, and the A path is input to the optical fiber splitter 2 .

[0040] The optical fiber beam splitter 2 is a 90 / 10 optical fiber beam splitter, and the A-path laser is then divided into the E-path with 90% energy and the F-path with 10% energy through the 90 / 10 optical fiber beam splitter 2.

[0041] The optical fiber beam splitter 3 is a 45 / 55 optical fiber beam splitter. After passing through the optical fiber modulator, the B-path laser is divided into the C path with 45% energy and the D path with 55% energy through the 45 / 55 optical fiber beam splitter 3.

[0042] The E-path laser is reflected by the mirror, coupled by the aspheric len...

Embodiment 3

[0047]An all-fiber laser detection system for tunnel safety monitoring, its structure is as described in Embodiment 2, the difference is that the data acquisition processing and control system generates a modulation signal to drive the laser.

[0048] The modulation signal is a triangular wave signal, and the wavelength period of the modulation signal is T, T=T1+T2+T3; at the time 0-T1, the sine signal and the rise time triangular wave signal are used to measure the water vapor, and at the time T1-T2, the sine wave is used Signal and rising time triangular wave signal to realize methane measurement; at T2-T3 time, use falling time triangular wave signal to realize displacement and deformation monitoring of the system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com