Controllable synthesis method of yolk-shell type silicon/carbon composite negative electrode material

A negative electrode material, carbon composite technology, applied in the direction of negative electrode, battery electrode, active material electrode, etc., to achieve the effect of low cost, convenient for large-scale production, and elimination of volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

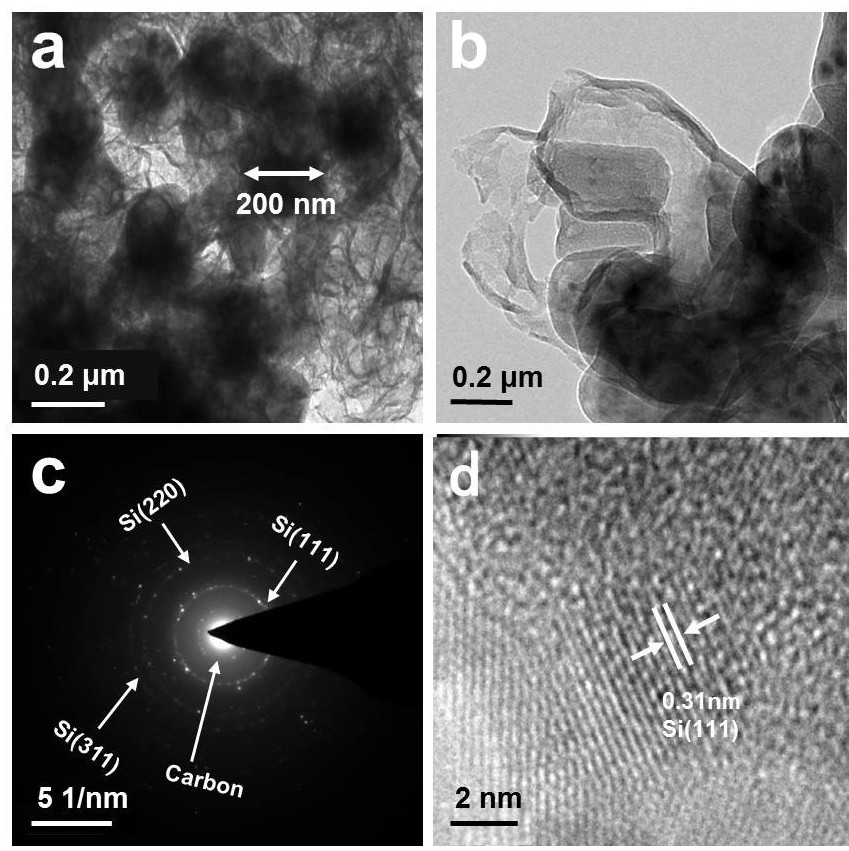

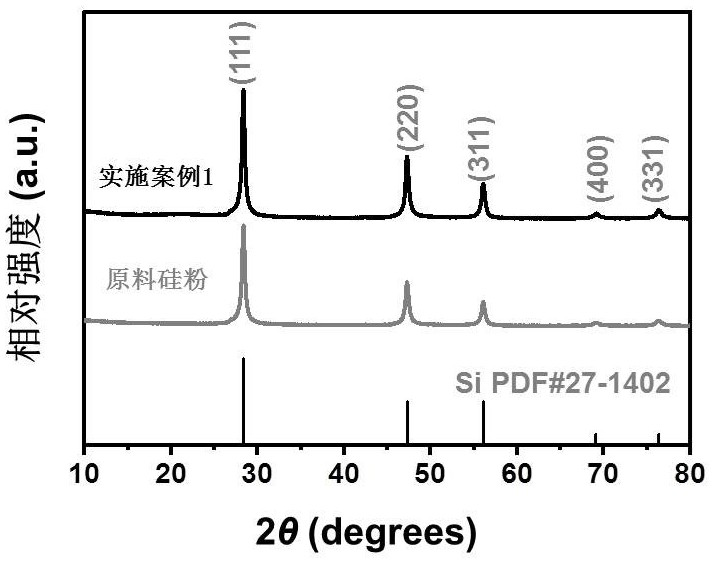

Embodiment example 1

[0031] Step 1. Add 1.2 g of silicon powder to 160 mL of deionized water, dropwise add 6 mL of absolute ethanol to form a silicon raw material solution, and raise the temperature of the water bath to 50 °C; dropwise add 5 mL of 0.04 g L -1 Sodium hydroxide solution, 500 rpm -1 Stir magnetically for 1 h; then suction filter the silicon raw material solution, wash with deionized water and absolute ethanol in turn, transfer to a vacuum oven, and dry at 60 °C for 8 h; obtain silicon / silicon oxide powder; step 2 .Put 0.4 g of the synthetic silicon / silicon oxide powder in step 1 and 0.04 g of glucose into 20 mL of deionized water, and sonicate for 1 h to obtain a mixed solution of silicon powder and glucose; then, heat the solution at 150 °C for 6 h; Centrifuge the solution in the hydrothermal kettle, wash the hydrothermal product with deionized water and absolute ethanol, place it in a vacuum oven at 80 °C, and dry it for 12 h; Under hydrogen atmosphere, anneal at 750 °C for 6 h, a...

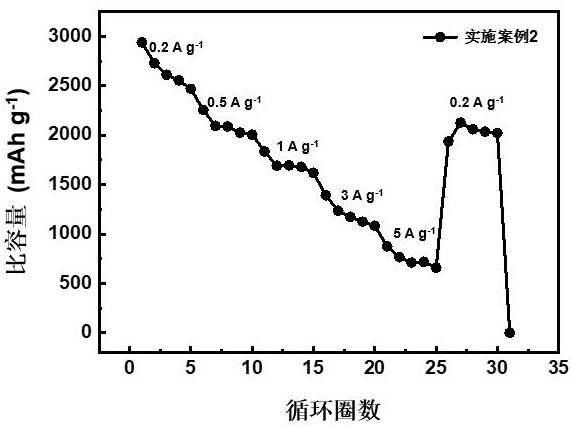

Embodiment example 2

[0033]Step 1. Add 1.2 g of silicon powder to 160 mL of deionized water, add 1 mL of absolute ethanol dropwise to form a silicon raw material solution, and heat up to 50 °C in a water bath; add 5 ml of 0.04 g / L lithium hydroxide solution dropwise, 500 r min -1 Stir magnetically for 1 h; then suction filter the silicon raw material solution, wash with deionized water and absolute ethanol in turn, transfer to a vacuum oven, and dry at 60 °C for 8 h; obtain silicon / silicon oxide powder; step 2 .Put 0.5 g of the synthetic silicon / silicon oxide powder and 0.05 g of glucose in 10 mL of deionized water into 10 mL of deionized water, and sonicate for 2 h to obtain a mixed solution of silicon powder and glucose; then, heat the solution at 150 °C for 6 h; Centrifuge the solution in the hydrothermal kettle, wash the hydrothermal product with deionized water and absolute ethanol, place it in a vacuum oven at 80 °C, and dry it for 12 h; Under hydrogen atmosphere, anneal at 750 °C for 6 h, ...

Embodiment example 3

[0035] Step 1. Add 2 g of silicon powder to 160 mL of deionized water, add dropwise 1 mL of absolute ethanol to form a silicon raw material solution, and heat up to 50 °C in a water bath; dropwise add 10 mL of 0.64 g L -1 Sodium hydroxide solution, 500 r min -1 Stir magnetically for 2 h; then suction filter the silicon raw material solution, wash with deionized water and absolute ethanol in turn, transfer to a vacuum oven, and dry at 60 °C for 8 h; obtain silicon / silicon oxide powder; step 2 .Put 0.5 g of the synthetic silicon / silicon oxide powder and 0.2 g of citric acid in 10 mL of deionized water in step 1, and sonicate for 2 h to obtain a mixed solution of silicon powder and citric acid; then, heat the solution at 120 °C for 6 h; Suction filter the solution in the hydrothermal kettle, wash the hydrothermal product with deionized water and absolute ethanol, place it in a vacuum oven at 80 °C, and dry it for 12 h. Subsequently, the hydrothermal product was put into a tube f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com