Microfluidic-based conventional azide preparation system and synthesis process

A technology for azide and preparation system, applied in the direction of azide/azide/halogen azide, laboratory containers, chemical instruments and methods, etc., which can solve the problems of poor product performance, high risk and high efficiency Low-level problems, to achieve the effect of low environmental pollution, reduced risk, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

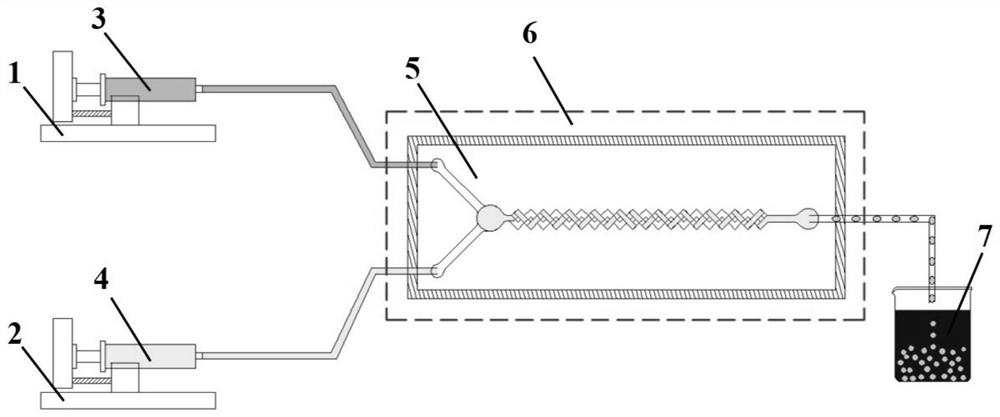

[0039] Example 1: Preparation and Product Characterization of Silver Silver Silver

[0040] 10 ml of 0.1 mol / L of silver nitrate solution was prepared, 10 ml of azide solution of 0.1 mol / L, a sodium carboxymethylcellulose solution was formulated, and the sodium carboxymethylcellulose sodium solution was quantified. Sodium nitride solution. Two reaction solutions were placed in the pumping device 1 and the pumping device 2, respectively, and the insection rate was 5.0 ml / min. The temperature control device temperature is set to 65 ° C. When the temperature is heated to the set temperature, the pumping device 1 and the pumping device 2 are opened, and the nitrate silver solution 3 and the azide solution 4 flow into the microfluidic chip 5, silver nitrate solution 3 and the sodium sodium nitride solution 4 The microfluidic chip 5 is internally contacted and the reaction is mixed, and the azide suspension is produced. The azide suspension flowing from the microfluidic chip 5 is ...

Embodiment 2

[0041] Example 2: Preparation and Product Characterization of Azurized Pres

[0042] 10 ml of 0.1 mol / L of the nitrate solution, 10 ml of 0.1 mol / L of azide solution, 0.05% sodium carboxymethylcellulose sodium solution, quantified 0.5 ml of carboxymethylcellulose sodium solution is dissolved in stack Sodium nitride solution. Two reaction solutions were placed in the pumping device 1 and the pumping device 2, respectively, and the insection rate was 5.0 ml / min. The temperature control device temperature is set to 65 ° C. When the temperature is heated to the set temperature, open the pumping device 1 and the pumping device 2, push the nitrate lead 3 and the azide solution 4 flow into the microfluidic chip 5, the nitrate lead solution 3 and the azide solution 4 The microfluidic chip 5 is internally contacted and the reaction is mixed, and the azide lead suspension is produced. The azide lead suspension flowing from the microfluidic chip 5 was collected to the collecting unit 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com