Nano-reinforced water-permeable material, water-permeable floor tile and water-permeable pavement

A technology of nano-enhanced and permeable materials, which is applied in the fields of nano-enhanced permeable materials, permeable floor tiles and permeable pavements, can solve the problems of low urban groundwater level, affecting the effective use of rainwater, and increasing the load of municipal drainage systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

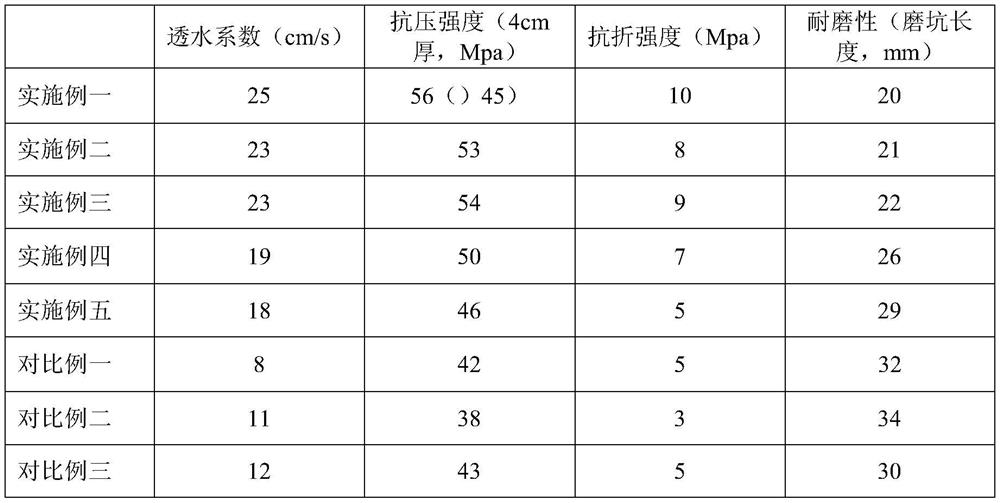

Embodiment 1

[0028] The nano-reinforced water-permeable material of this embodiment includes the following raw materials in parts by weight: 85 parts of aggregate; 8 parts of active molecular sieve powder; 11 parts of nano-calcium carbonate; 7 parts of nano-titanium dioxide; 3 parts of defoaming agent; 6 parts of water reducing agent; 52 parts of high-strength toughening agent; 45 parts of high-strength binder; 6 parts of holmium oxide.

[0029] In this embodiment, the active molecular sieve powder may be a potassium salt of hydrated aluminum silicate that has been calcined at a high temperature.

[0030] The high-strength toughener can include the following raw materials in parts by weight: 13 parts of carboxyl-terminated liquid nitrile rubber, 10 parts of polyvinyl butyral, 10 parts of polyvinyl alcohol, 14 parts of sodium silicate, 8 parts of magnesium carbonate; graphite powder 14 parts, polypropylene fiber 7 parts.

[0031] The high-strength binder can include the following raw mater...

Embodiment 2

[0037] The nano-reinforced water-permeable material of this embodiment includes the following raw materials in parts by weight: 70 parts of aggregate; 6 parts of active molecular sieve powder; 8 parts of nano-calcium carbonate; 5 parts of nano-titanium dioxide; 2 parts of defoaming agent; 5 parts of water reducing agent; 40 parts of high-strength toughening agent; 35 parts of high-strength binder; 4 parts of holmium oxide.

[0038] In this embodiment, the active molecular sieve powder is a sodium salt of hydrated aluminum silicate that has been calcined at a high temperature.

[0039] The high-strength toughener can include the following raw materials in parts by weight: 10 parts of carboxyl-terminated liquid nitrile rubber, 8 parts of polyvinyl butyral, 8 parts of polyvinyl alcohol, 8 parts of sodium silicate, 5 parts of magnesium carbonate; graphite powder 10 parts, polypropylene fiber 5 parts.

[0040] The high-strength binder can include the following raw materials in par...

Embodiment 3

[0043] The nano-reinforced water-permeable material of this embodiment includes the following raw materials in parts by weight: 100 parts of aggregate; 10 parts of active molecular sieve powder; 15 parts of nano-calcium carbonate; 8 parts of nano-titanium dioxide; 4 parts of defoaming agent; 8 parts of water-reducing agent; 60 parts of high-strength toughening agent; 50 parts of high-strength binder; 8 parts of holmium oxide.

[0044] In this embodiment, the active molecular sieve powder is a potassium salt of hydrated aluminum silicate that has been calcined at a high temperature.

[0045] The high-strength toughener can include the following raw materials in parts by weight: 15 parts of carboxyl-terminated liquid nitrile rubber, 12 parts of polyvinyl butyral, 12 parts of polyvinyl alcohol, 16 parts of sodium silicate, 10 parts of magnesium carbonate; graphite powder 20 parts, polypropylene fiber 10 parts.

[0046] The high-strength binder can include the following raw mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com