Environment-friendly preparation process of light magnesium oxysulfate wall material

A magnesium oxysulfide wall and a preparation technology, which is applied in the field of building materials, can solve the problems of high temperature resistance, secondary pollution, acid and alkali resistance, etc., and achieve good environmental performance and good sound insulation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

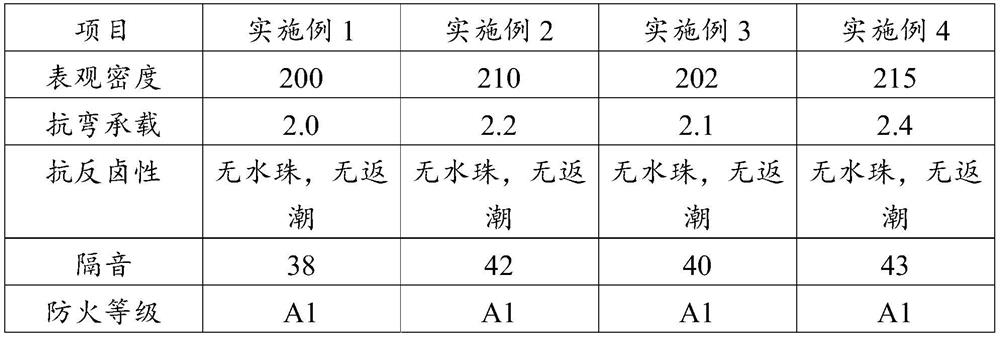

Examples

Embodiment 1

[0025] This embodiment discloses an environmentally friendly preparation process for lightweight magnesium oxysulfide wall materials, including the following steps:

[0026] S1: In parts by weight, at 30°C, 40 parts of light-burned magnesia powder (the magnesia content of the light-burned magnesia powder is 72 to 76%, the silicon dioxide content is 7 to 9%, and the calcium oxide content is 2 to 3%), 40 parts of magnesium sulfate solution (raw materials selected from anhydrous magnesium sulfate with a purity of ≥95%) and 1 part of magnesium oxysulfide modifier and stirred for 5 minutes to obtain the first mixture;

[0027] S2: At 50°C, mix 20 parts of polystyrene particles, 10 parts of foaming agent (the foaming agent is a special foaming agent for composite magnesite, and its foam diameter is 0.5 to 0.8mm), 10 parts of fly ash, 5 parts of blowing agent foam and 50 parts of the first mixture were placed in a high-speed mixer with a rotation speed of 1000 r / min and stirred at hi...

Embodiment 2

[0032] This embodiment discloses an environmentally friendly preparation process for lightweight magnesium oxysulfide wall materials, including the following steps:

[0033] S1: In parts by weight, at 33°C, 43 parts of light-burned magnesia powder (the magnesia content of the light-burned magnesia powder is 72 to 76%, the silicon dioxide content is 7 to 9%, and the calcium oxide content is 2 to 3%), 43 parts of magnesium sulfate solution (raw material selected from magnesium sulfate monohydrate with purity ≥ 95%) and 2 parts of magnesium oxysulfide modifier and stirred for 7 minutes to obtain the first mixture;

[0034] S2: At 53°C, 23 parts of polystyrene particles, 13 parts of foaming agent (the foaming agent is a special foaming agent for composite magnesite, and its foam diameter is 0.5 to 0.8 mm), 13 parts of silica fume, 7 parts One part of blowing agent foam and 53 parts of the first mixture were placed at a speed of 1200r / min in a high-speed mixer for 18min to obtain t...

Embodiment 3

[0039] This embodiment discloses an environmentally friendly preparation process for lightweight magnesium oxysulfide wall materials, including the following steps:

[0040] S1: According to parts by weight, at 36°C, 46 parts of light-burned magnesia powder (the content of magnesia in the light-burned magnesia powder is 72 to 76%, the content of silicon dioxide is 7 to 9%, and the content of calcium oxide is 2 to 3%), 46 parts of magnesium sulfate solution (raw material selected from magnesium sulfate heptahydrate with a purity of ≥95%) and 4 parts of magnesium oxysulfide modifier and stirred for 8 minutes to obtain the first mixture;

[0041] S2: At 56°C, 30 parts of polystyrene particles, 16 parts of foaming agent (the foaming agent is a special foaming agent for composite magnesite, and its foam diameter is 0.5 to 0.8mm), 16 parts of active slag, 8 One part of blowing agent foam and 56 parts of the first mixture were placed at a speed of 1600 r / min in a high-speed mixer for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com