Preparation of AFE capacitor with high energy storage density and high energy storage efficiency, anti-ferroelectric film layer and preparation thereof and flexible AFE capacitor

A capacitor and film layer technology, which is applied in the direction of fixed capacitor dielectric, hybrid/electric double layer capacitor manufacturing, multilayer capacitor, etc. Lattice matching degree, simple preparation method, and the effect of improving energy storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

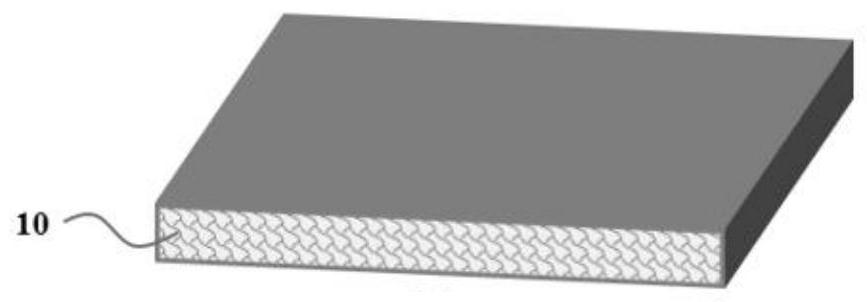

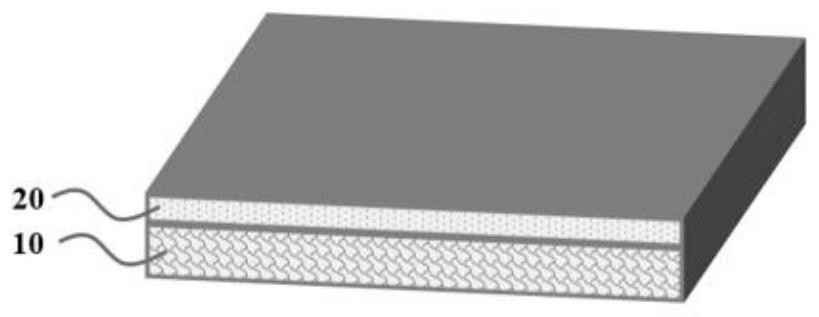

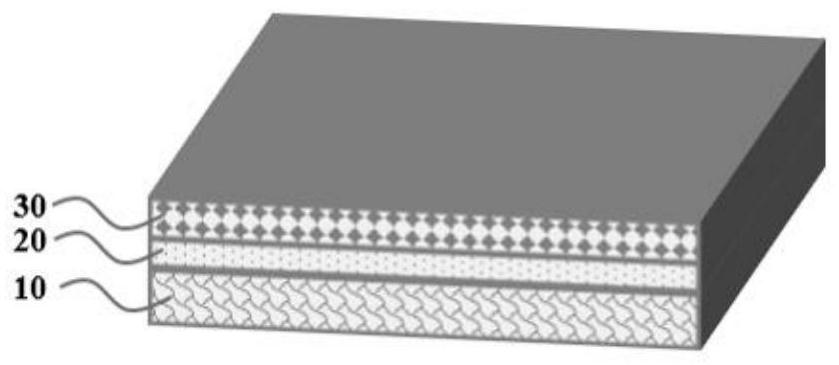

[0087] Most AFE capacitors are difficult to achieve a higher breakdown voltage while achieving sufficiently large polarization, which makes the actual energy storage performance of the AFE capacitor greatly reduced. To this end, the present application provides a method of preparing a high reservoir density, high storage efficiency, as shown in Figure 1, including the following steps:

[0088] The buffer layer 20 is deposited on the substrate 10;

[0089] A first electrode layer 30 is deposited on the buffer layer 20;

[0090] Anti-ferrous electrical thin film layer 40 containing two or more thin films is deposited on the first electrode layer 30;

[0091] A second electrode layer 50 is deposited on the antiferromic thin film layer 40 to obtain an AFE capacitor;

[0092] Among them therein, the antifer electrical thin film layer 40 is deposited by a pulsed laser, and the elements contained in the adjacent film may be the same or different.

[0093] The antifer electrical thin film...

Embodiment 1

[0120] A method of preparing a pure PLZT of high energy storage density and high storage efficiency on a flexible substrate, including the following steps:

[0121] (1) Select the flexible substrate while cleaning the pretreatment, and then performs bonding; the thickness of the flexible substrate is 30 nm, and the pretreatment includes the following steps:

[0122] A. Select the surface of the surface of the surface as a flexible substrate, the MICA substrate crystal plane orientation (001), as a new type of flexible transparent insulating substrate having a single-oblique crystal structure, can be used for some functional oxide capacitor Growth, thereby further achieving the performance of PLZT-STO regulating different excitation aromal components;

[0123] b, with a polyimide tape to work on the work desktop to make it flat;

[0124] C. Clean a complete MICA substrate to a polyimide tape attached to the desktop with tweezers to adhere the peeling;

[0125] D. Repeat step C unti...

Embodiment 2

[0137] A method of preparing high energy storage density and high storage efficiency on a flexible substrate, including the following steps:

[0138] (1) Select the flexible substrate while cleaning the pretreatment, and then performs bonding; the thickness of the flexible substrate is 30 nm, and the pretreatment includes the following steps:

[0139] A. Select the surface of the surface of the surface as a flexible substrate, the MICA substrate crystal plane orientation (001), as a new type of flexible transparent insulating substrate having a single-oblique crystal structure, can be used for some functional oxide capacitor Growth, thereby further achieving the performance of PLZT-STO regulating different excitation aromal components;

[0140] b, with a polyimide tape to work on the work desktop to make it flat;

[0141] C. Clean a complete MICA substrate to a polyimide tape attached to the desktop with tweezers to adhere the peeling;

[0142] D. Repeat step C until the stripping...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com