Cosmetic composition, cosmetic, and brush

A technology of composition and cosmetics, applied in the direction of cosmetics, packaged cosmetics, cosmetic preparations, etc., can solve the problems of excessive discharge of contents, unsightly appearance, etc., and achieve minimization of bristle marks, excellent use feeling, covering power and Excellent moisturizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and comparative example 1 to comparative example 3

[0126] (1) Preparation of cosmetic composition

[0127] The following Table 1 shows the composition of the cosmetic composition used for the preparation, and the cosmetic composition was prepared according to the following composition.

[0128] Heat the oil phase part (oil thickener / oil / emulsifier) at 90°C to 95°C while dissolving the oil thickener, add the thickener and disperse it, then add solid powder pigment and disperse it Emulsify.

[0129] Put all the humectant / preservative / emulsion stabilizer / water phase thickener into the solvent, that is, purified water, and heat at 90°C to 95°C to dissolve the water phase thickener, thereby preparing the water phase.

[0130] After that, after mixing the above-mentioned emulsified oil phase and water phase, a fragrance, a thickener, and a solid powder pigment are added to prepare a cosmetic composition of a cream preparation.

[0131] [Table 1]

[0132]

[0133]

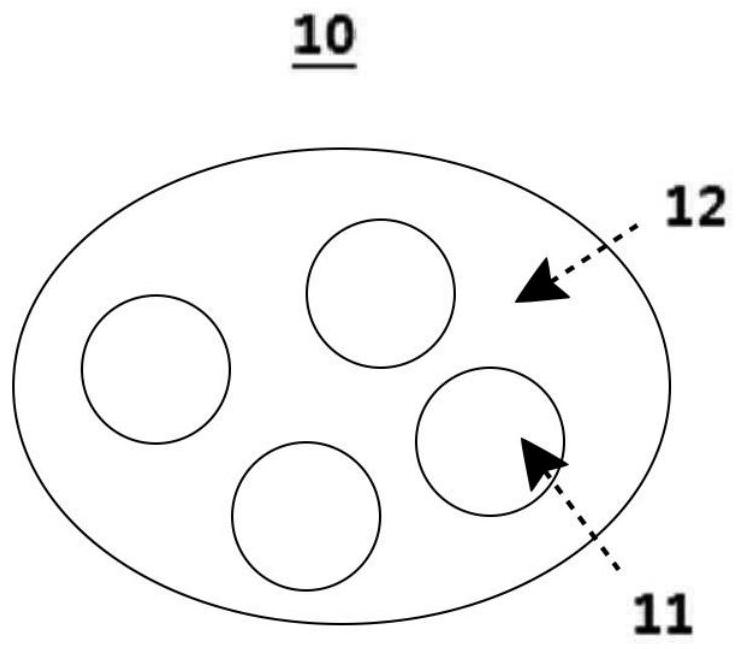

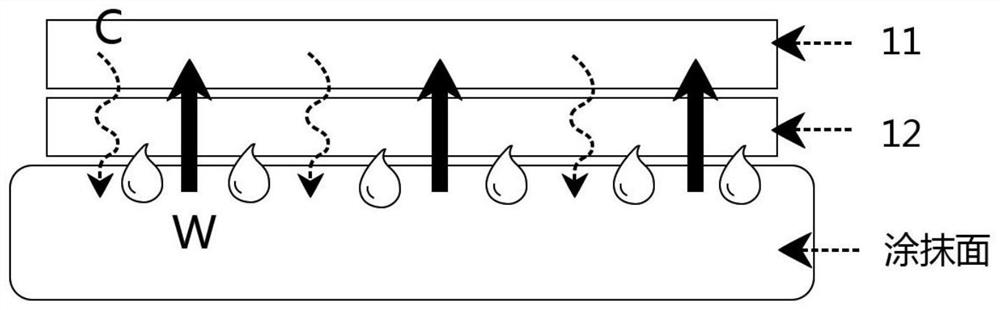

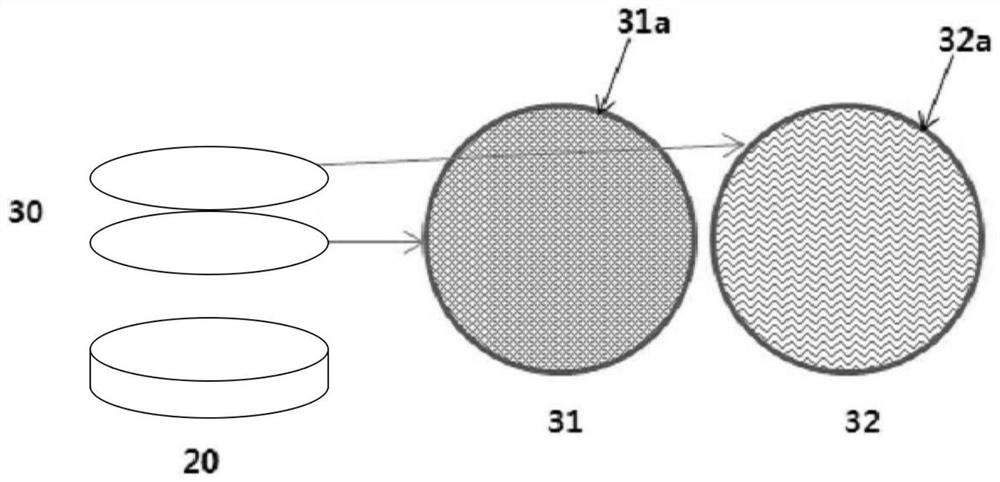

[0134] (2) Manufacturing of cosmetics including double sc...

experiment example 1

[0143] Experimental Example 1: Viscosity Measurement

[0144] For the cosmetics prepared in Example 1 and Comparative Examples 1 to 3, respectively, the viscosity by temperature and pressure was measured.

[0145] (1) Viscosity based on temperature

[0146] For the cosmetics prepared in Example 1 and Comparative Examples 1 to 3, the viscosities at temperatures of 30° and 60° were respectively measured. At this time, Brookfield DV-III ULTRA was used as a viscosity measuring device to measure the viscosity under the conditions of No. 29 spindle, 5 revolutions (rpm) and 2 minutes (min), and the results are shown below Table 2.

[0147] [Table 2]

[0148] temperature Example Comparative example 1 Comparative example 2 Comparative example 3 30℃ 90,000 cps 35,000 cps 37,000cps 87,000cps 60℃ 35,000 cps 30,000 cps 31,000 cps 34,000 cps

[0149] Referring to the above-mentioned Table 2, it can be seen that Example 1 has a larger viscosi...

experiment example 2

[0160] Experimental example 2: Measurement of storage stability, discharge force and appearance quality

[0161] With respect to the cosmetics produced in Example 1 and Comparative Example 4, respectively, the storage stability and discharge force of the mesh-based cosmetics were measured.

[0162] (1) Storage stability test of cosmetics including double sieve

[0163] As a result of storing the cosmetic containing the double mesh produced in Example 1 at 55° C. for 3 days, it was confirmed that the cosmetic composition was stably stored by the double mesh.

[0164] It was confirmed that the cosmetic material was discharged through the double screen only when a certain pressure such as 2kgf was applied.

[0165] (2) Measurement of discharge force of cosmetics including double screens

[0166] For the cosmetics including double sieves produced in Example 1, after adjusting the hole size of the first sieve, a pressure of 2 kgf was applied to measure the discharge amount of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com