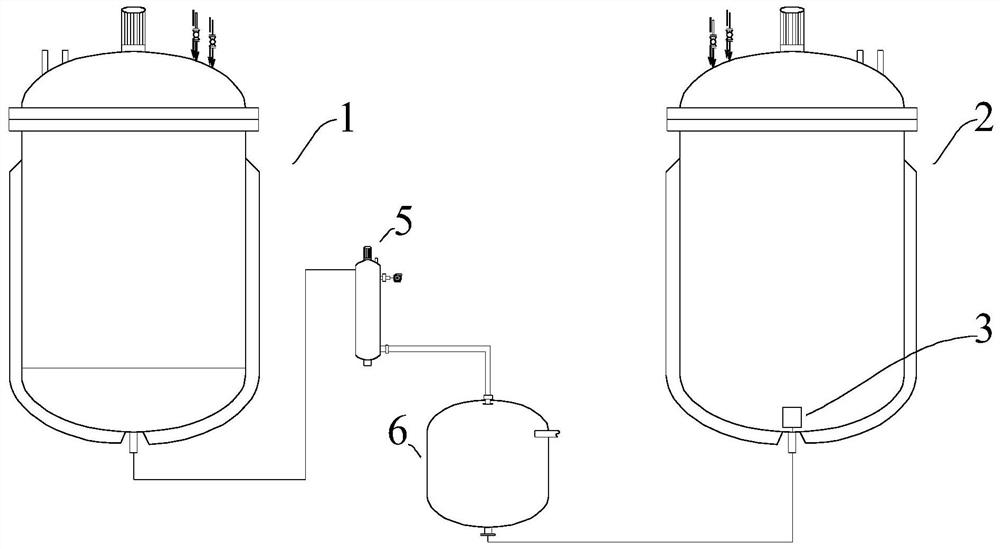

Strengthening system and process for preparing 1, 4-butanediol through allyl alcohol hydrogenation

A technology for preparing allyl alcohol and hydrogen, applied in the field of strengthening systems, can solve problems such as inconvenience, difficulty in greatly improving the reaction rate, and influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

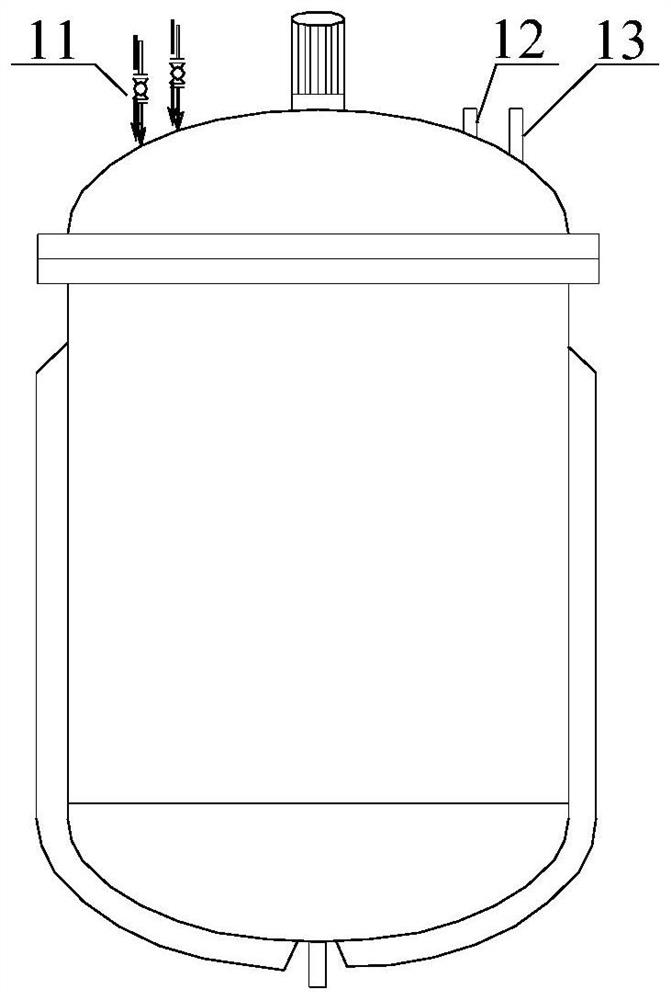

[0111] The reaction temperature of the primary hydrogenation reaction is: 55° C., the reaction pressure is: 0.05 MPa; the catalyst is triphenylphosphine complexed rhodium; the selectivity of γ-hydroxybutanol is: 82%.

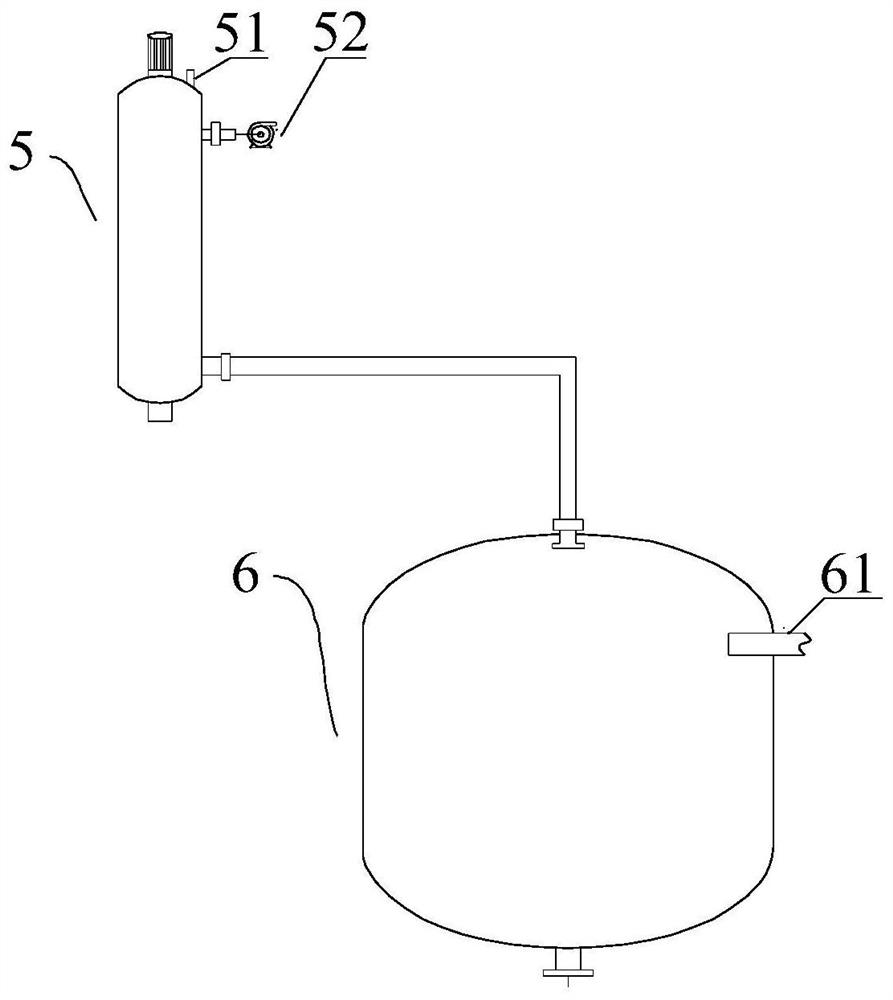

[0112] Before the secondary hydrogenation, γ-hydroxybutanol and hydrogen enter the micro interface generator 3 for micronization treatment;

[0113] The reaction temperature of the secondary hydrogenation reaction is: 85°C; the catalyst is Wright's nickel; the selectivity of 1,4-butanediol is: 80%.

Embodiment 2

[0115] The reaction temperature of the primary hydrogenation reaction is: 70° C., the reaction pressure is: 0.5 MPa; the catalyst is triphenylphosphine complexed rhodium; the selectivity of γ-hydroxybutanol is: 75%.

[0116] Before the secondary hydrogenation, γ-hydroxybutanol and hydrogen enter the micro interface generator 3 for micronization treatment;

[0117] The reaction temperature of the secondary hydrogenation reaction is: 100°C; the catalyst is Wright's nickel; the selectivity of 1,4-butanediol is: 76%.

Embodiment 3

[0119] The reaction temperature of the primary hydrogenation reaction is: 65°C, the reaction pressure is: 0.4MPa; the catalyst is triphenylphosphine complexed rhodium; the selectivity of γ-hydroxybutanol is 78:%.

[0120] Before the secondary hydrogenation, γ-hydroxybutanol and hydrogen enter the micro interface generator 3 for micronization treatment;

[0121] The reaction temperature of the secondary hydrogenation reaction is: 95°C; the catalyst is Wright's nickel; the selectivity of 1,4-butanediol is: 75%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com