Process for dechlorinating and refining dimethyl carbonate crude product of gas-phase carbonyl method

A technology of dimethyl carbonate and dimethyl chlorocarbonate, which is applied in the field of chemical technology, can solve the problem of not finding similar technical published patent documents, etc., achieves convenient and efficient daily equipment management and daily operation, saves construction costs, reduces The effect of construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

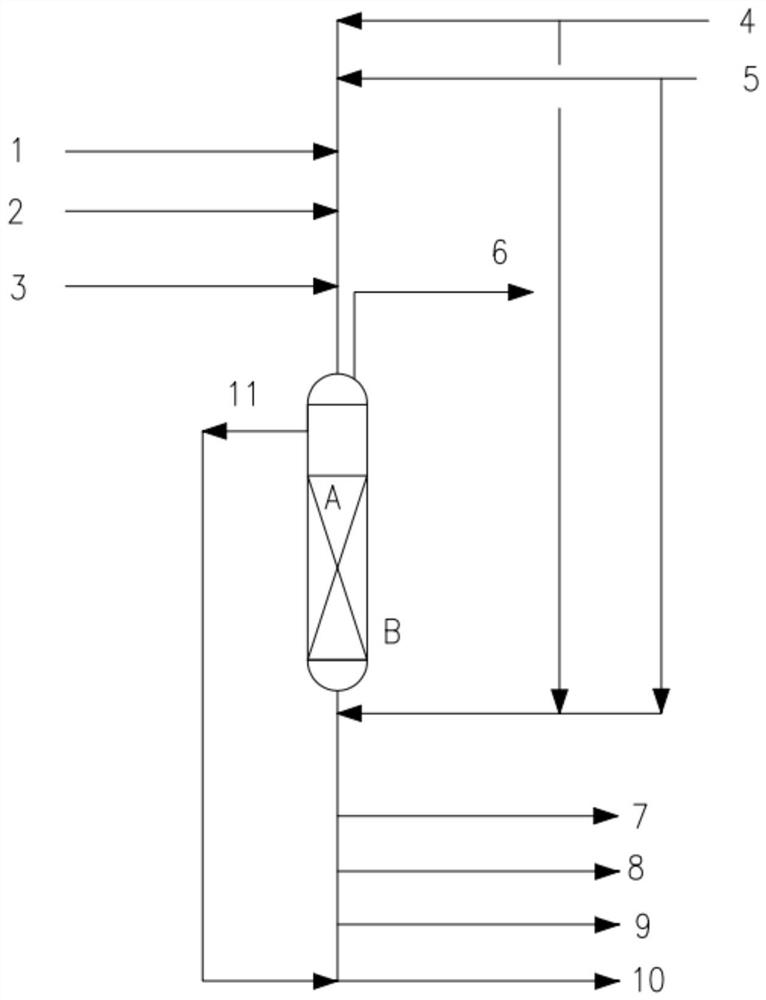

Image

Examples

Embodiment 1

[0047] 10.0M 3 The strong alkaline resin, loading the resin into the resin column; the resin tower structure includes, the cylinder, a liquid distributor connected to the feed port, a support plate, a heat pipe, or the like. Under temperature 60.0 ° C and pressure of 0.1 MPa (g), dimethyl carbonate prepared by gas phase carbonyl method was dichlorinated, and the flow rate was 20000.0 kg / h (there in the oxalate concentration of 58.0%, methyl carbonate The ester concentration was 35.0%, the concentration of methanol 1 was 6.0%, and the other 1.0%) was filtered through a fixed bed B, and the chloride ion concentration bits were 16.0 ppm in front of the crude product. Through the adsorption of the strong alkaline resin, a trace chloride ion remaining in the dialthyl carbonate prepared by gas phase carbonyl is adsorbed, and the chloride ion concentration of 0.8 ppm after filtration is filtered, and dimethylcarbonate. The crude product can be sent to the subsequent distillation sectio...

Embodiment 2

[0055] 20.0m 3 The strong alkaline resin, loading the resin into the resin column; the resin tower structure includes, the cylinder, a liquid distributor connected to the feed port, a support plate, a heat pipe, or the like. Under temperature of 70.0 ° C and pressure 0.2 MPa (g), dimethyl carbonate prepared by gas phase carbonyl method was dichlorinated, and its flow rate was 25,000.0 kg / h (there in the oxalate concentration of 67.0%, bicarbonate The ester concentration was 28.0%, the methanol 1 concentration was 4.0%, and the other 1.0%) was filtered through a fixed bed B, and the chloride ion concentration bits were 40.0 ppm in front of the crude product. Through the adsorption of the strong alkaline resin, a trace chloride ion remaining in the dialthyl carbonate prepared by gas phase carbonyl is adsorbed, and the chloride concentration of the chloride ion is 1.2 ppm after filtration, and dimethyl carbonate. The crude product can be sent to the subsequent distillation section....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com