High-thermal-conductivity insulating silica gel gasket and preparation method thereof

An insulating silica gel, high thermal conductivity technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of high price and low thermal conductivity, achieve high thermal conductivity, reduce costs, and broaden the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also proposes a preparation method for the above-mentioned high thermal conductivity insulating silica gel gasket, which includes the following steps: weighing each component according to the weight ratio, vacuum kneading vinyl silicone oil, thermal conductivity filler, and modifier for 30-40 minutes to obtain the base Then mix the base glue, cross-linking agent and inhibitor fully for 20-30 minutes, and finally add the platinum catalyst and vacuum mix for 15-20 minutes to obtain the mixed rubber, and then put it on the calender to be calendered and solidified with a certain temperature gradient. Obtain the heat-conducting silica gel gasket.

[0036] Preferably, the temperature range of the drying tunnel of the calender is divided into three temperature sections: 60-80°C, 90-110°C, and 120-150°C.

Embodiment 1

[0038] High thermal conductivity insulating silicone gasket, its raw materials include: 100 parts of vinyl silicone oil with a viscosity of 500mPa.s, 1500 parts of modified spherical alumina, 500 parts of nano-aluminum nitride, 3 parts of 202 high hydrogen-containing silicone oil, UC- 2 parts of 616-terminal hydrogen silicone oil, 3 parts of hexamethyldisilazane, 1 part of platinum catalyst, 0.05 part of acetylenic alcohol inhibitor;

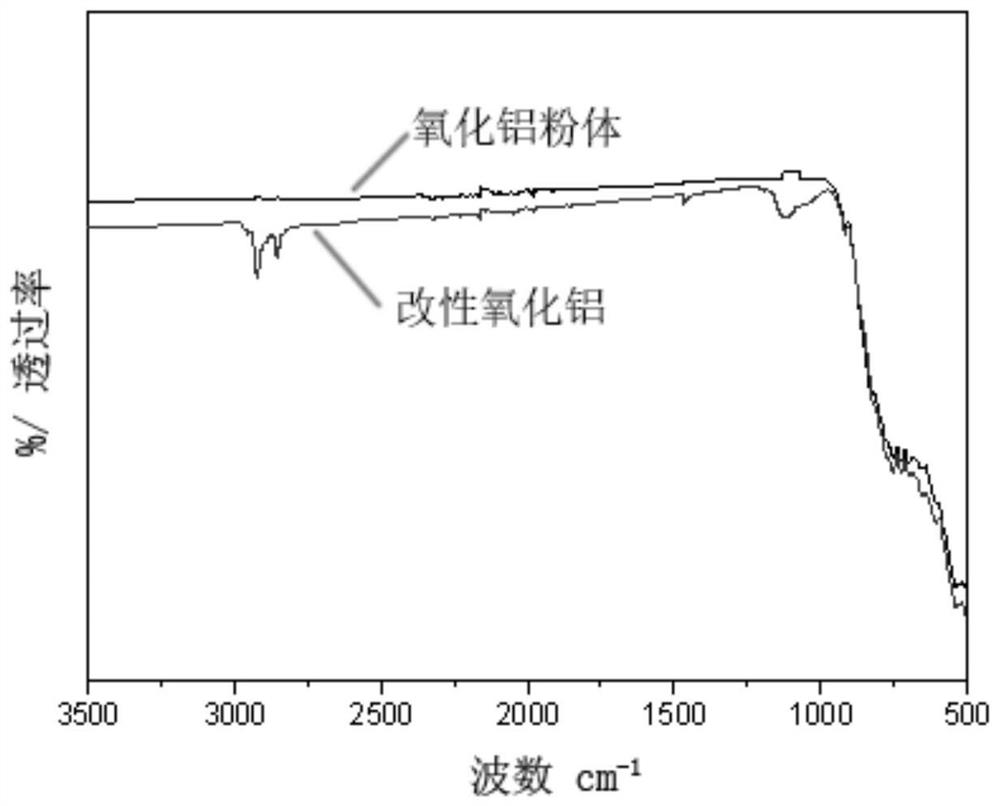

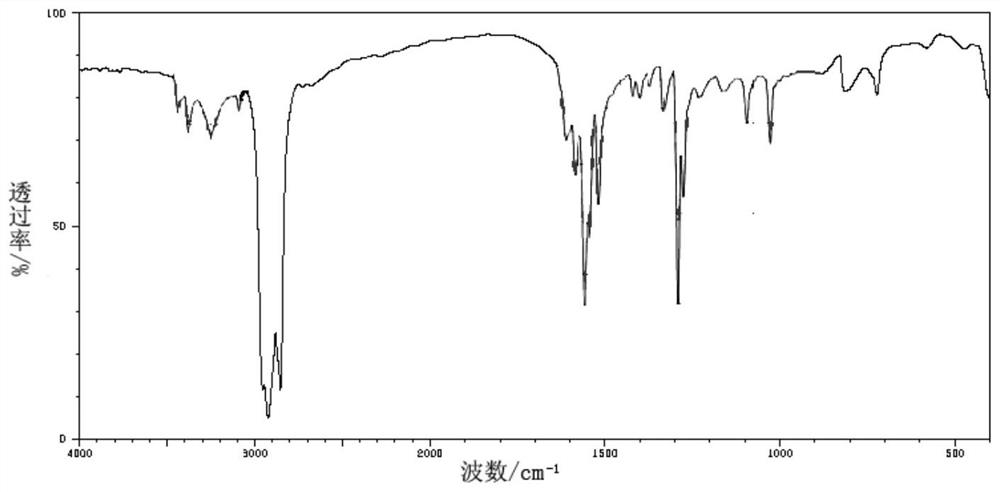

[0039] Among them, in the preparation process of modified spherical alumina, dodecamethyltrimethoxysilane was mixed with methanol and water, and ammonia water was used to adjust the pH value to alkaline, then spherical alumina was added, the temperature was raised to 75°C, and the temperature was kept and stirred for 3 hours. Cool to room temperature, wash with methanol three times, vacuum filter, and dry at 80°C for 24 hours to obtain dodecamethyltrimethoxysilane-modified spherical alumina; wherein, dodecamethyltrimethoxysilane and spherical alu...

Embodiment 2

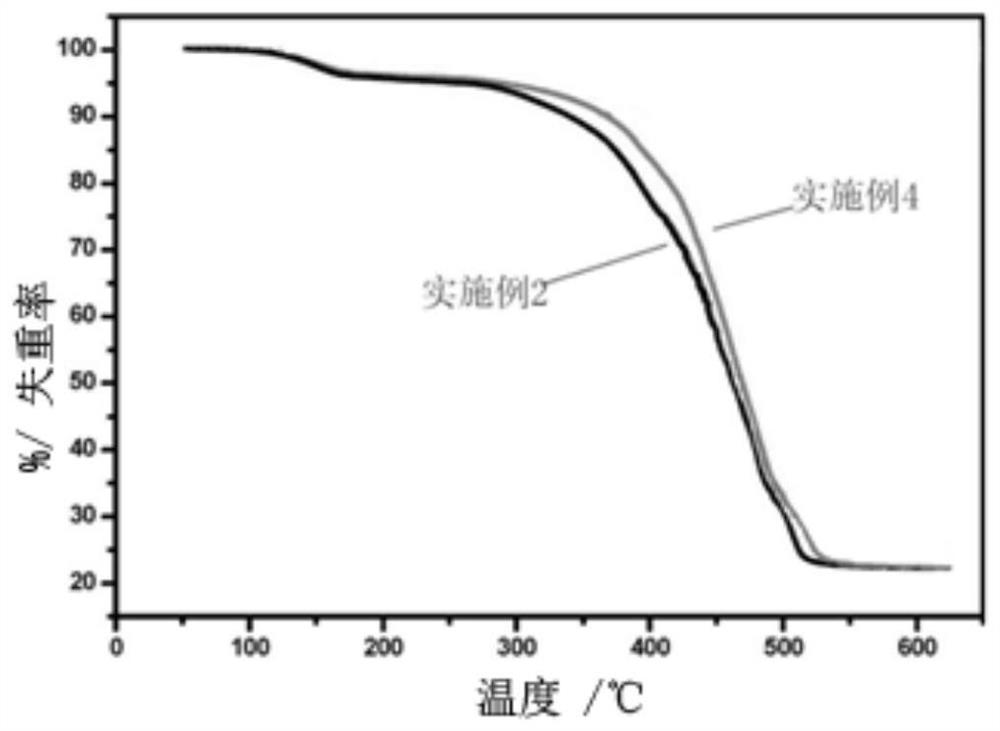

[0043] High thermal conductivity insulating silicone gasket, its raw materials include by mass: 100 parts of vinyl silicone oil with a viscosity of 800mPa.s, 700 parts of modified spherical alumina, 100 parts of cubic boron nitride, 2.5 parts of 202 high hydrogen-containing silicone oil, UC-616 1.5 parts of hydrogen-terminated silicone oil, 4 parts of vinyltriethoxysilane, 1 part of platinum catalyst, 0.05 parts of acetylenic alcohol inhibitor;

[0044] Among them, in the preparation process of modified spherical alumina, dodecamethyltrimethoxysilane was mixed with methanol and water, and ammonia water was used to adjust the pH value to alkaline, then spherical alumina was added, the temperature was raised to 75°C, and the temperature was kept and stirred for 3 hours. Cool to room temperature, wash with methanol three times, vacuum filter, and dry at 80°C for 24 hours to obtain dodecamethyltrimethoxysilane-modified spherical alumina; wherein, dodecamethyltrimethoxysilane and sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com