Preparation method of TiO2/iron-based MOF loaded functional fabric

A functional fabric, iron-based technology, applied in the direction of organic compound/hydride/coordination complex catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as difficult recycling, chromaticity problems, and easy agglomeration. Achieve the effect of reducing recombination rate, low cost and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A loaded TiO 2 The preparation method of the functional fabric of / iron-based MOF, concrete steps are as follows:

[0029] Step 1: Add 2 mmol of trimesic acid to 10 mL of 1M sodium hydroxide, and use 40KHZ ultrasonic treatment for 10 minutes to adjust the pH to 7 to obtain solution A;

[0030] The second step: 0.2 g of nylon fabric and 10% of the weight of the fabric nano-TiO 2 Add to solution A, and use 40KHZ ultrasonic treatment for 10 min;

[0031] Step 3: Add 3 mmol of ferrous sulfate heptahydrate into 30 mL of distilled water, and use 40KHZ ultrasonic treatment for 5 min to obtain solution B;

[0032] Step 4: Add solution B dropwise to solution A soaked in nylon fabric at a rate of 50-60 drops / min, and shake and react at room temperature for 12 hours. After the reaction, take out the nylon fabric, wash it with water, and dry it. Get functional fabrics.

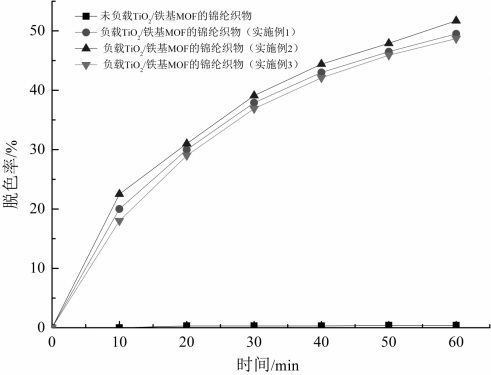

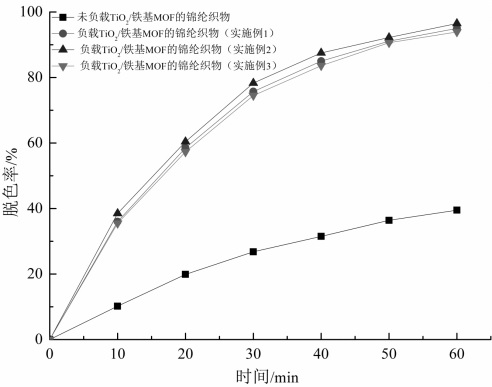

[0033] In order to investigate the adsorption effect of the prepared functional fabric on the dye, reactive b...

Embodiment 2

[0038] A loaded TiO 2 The preparation method of the functional fabric of / iron-based MOF, concrete steps are as follows:

[0039]Step 1: Add 3 mmol of trimesic acid to 15 mL of 1M sodium hydroxide, and use 40KHZ ultrasonic treatment for 10 minutes to adjust the pH to 6 to obtain solution A;

[0040] The second step: 0.3 g of nylon fabric and 30% of the weight of the fabric nano-TiO 2 Add to solution A, and use 40KHZ ultrasonic treatment for 20 min;

[0041] Step 3: Add 6 mmol of ferrous sulfate heptahydrate into 40 mL of distilled water, and use 40KHZ ultrasonic treatment for 5 min to obtain solution B;

[0042] Step 4: Add solution B dropwise to solution A soaked in nylon fabric at a rate of 50-60 drops / min, and shake and react at room temperature for 16 hours. After the reaction, take out the nylon fabric, wash it with water, and dry it. Get functional fabrics.

[0043] In order to investigate the adsorption effect of the prepared functional fabric on the dye, reactive bl...

Embodiment 3

[0048] A loaded TiO 2 The preparation method of the functional fabric of / iron-based MOF, concrete steps are as follows:

[0049] Step 1: Add 3 mmol of trimesic acid to 20 mL of 1M sodium hydroxide, use 40KHZ ultrasonic treatment for 10 minutes, adjust the pH to 8, and obtain solution A;

[0050] The second step: 0.4 g of nylon fabric and 20% of the weight of the fabric nano-TiO 2 Add to solution A, and use 40KHZ ultrasonic treatment for 20 min;

[0051] Step 3: Add 4 mmol of ferrous sulfate heptahydrate to 30 mL of distilled water, and use 40KHZ ultrasonic treatment for 5 min to obtain solution B;

[0052] Step 4: Add solution B dropwise to solution A soaked in nylon fabric at a rate of 50-60 drops / min, and shake and react at room temperature for 16 hours. After the reaction, take out the nylon fabric, wash it with water, and dry it. Get functional fabrics.

[0053] In order to investigate the adsorption effect of the prepared functional fabric on the dye, reactive black K...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com