A kind of darkening agent for nylon fabric and preparation method thereof

A darkening agent and fabric technology, applied in dyeing, textiles and papermaking, etc., can solve the problems of low refractive index, high cost, and unsatisfactory darkening effect of fluororesin, so as to improve hand feeling, increase added value, improve affinity The effect of water performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

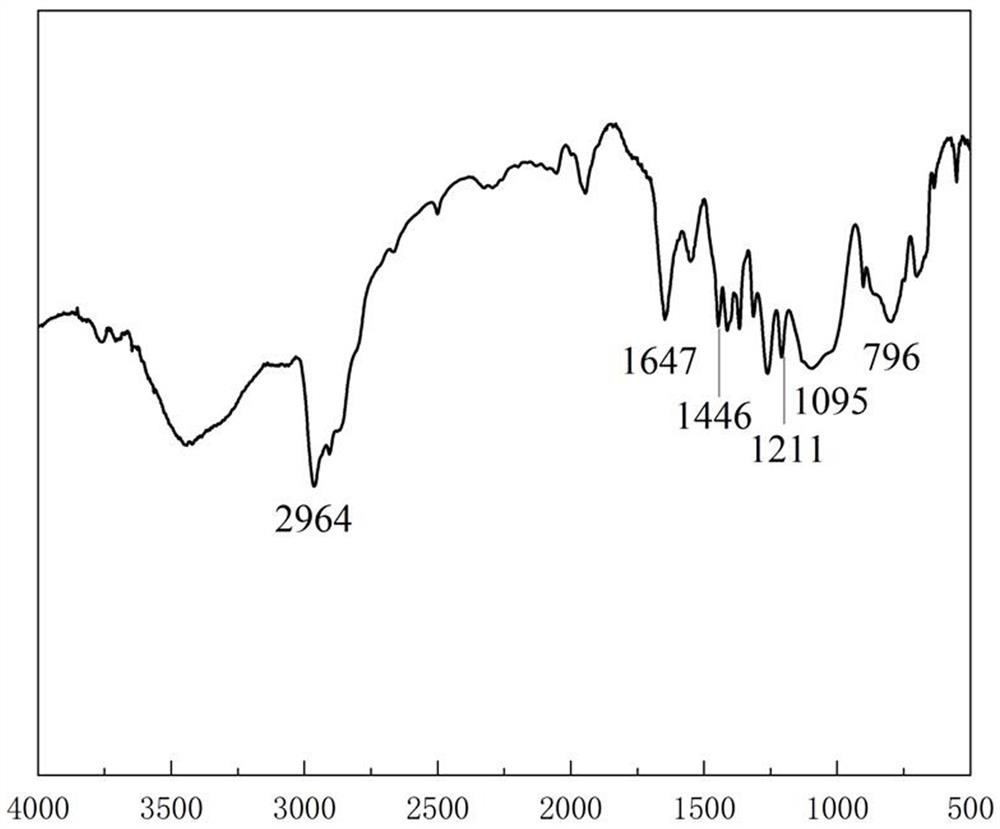

Embodiment 1

[0025] This embodiment provides a deeper agent for a nylon fabric, and the preparation method thereof is as follows:

[0026] 1. Add 100 g of polyether amine ED400, 24.3 g of adipic acid to the first reaction vessel with a stirrer and a condensation reflow device, open the condensation reflow device and a stirrer, and 1.86 g of subcatehite, start Heating, the temperature was raised to 175 ° C, then 2.48 g of phosphite triphenyl ester was added, and the temperature was continued to 220 to 230 ° C, and after 1 to 2 hours of the insulation reaction, the intermediate product I was obtained.

[0027] 2. A 150 g of octylcryline tetra siloxane, 50 g of trifluoropropylcline trialoxane and 20 g of epoxy double head are added to a second reaction vessel with a stirrer, and the agitator is turned on. The temperature was raised to 70 ° C, adding 0.18 g of tetramethylammonium hydroxide, continued to heat up 95 ° C, after the insulation reaction for 5 h, resulting in an intermediate product II....

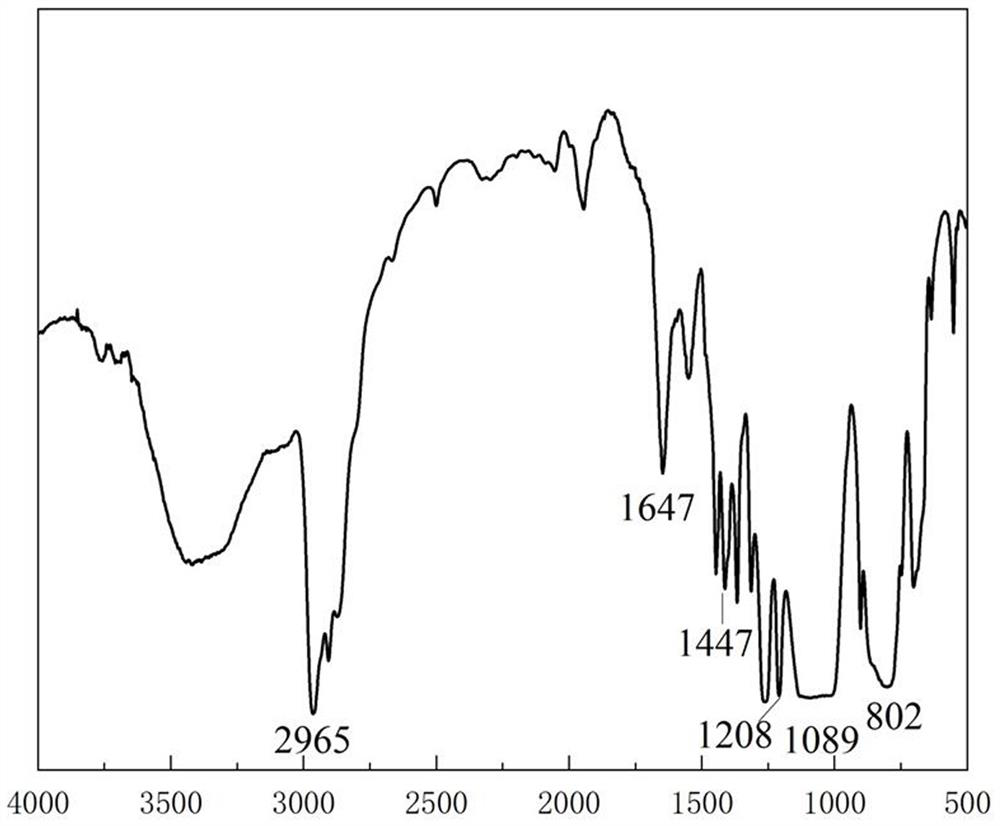

Embodiment 2

[0034] 1. A 150 g of polyether amine ED400, 70.5 g of polyether acid is added to the first reaction vessel with a stirrer and a condensate reflux device, open the condensation reflow device and a stirrer, add 4.41 g of subcateh with sodium, start Heating, the temperature was raised to 175 ° C, then 3.3 g of phosphite triphenyl ester was added, and the temperature was continued to 220 to 230 ° C, and after 1 to 2 hours of insulation reaction, the intermediate product I was obtained.

[0035] 2. 200 g of octylbarciomethyloxane, 100 g of trifluoropropylcline trialoxane and 29.8 g of epoxy double head are added to a second reaction vessel with a stirrer to open the stirrer. The temperature was raised to 70 ° C, 0.34 g of tetramethyl omodium hydroxide was added, and the temperature was warmed to 95 ° C, and the insulation reaction was allowed to obtain an intermediate product II.

[0036] 3. Add 300 g of intermediate II, 29.5 g of intermediates I and 141.2 g isopropyl alcohol to a thir...

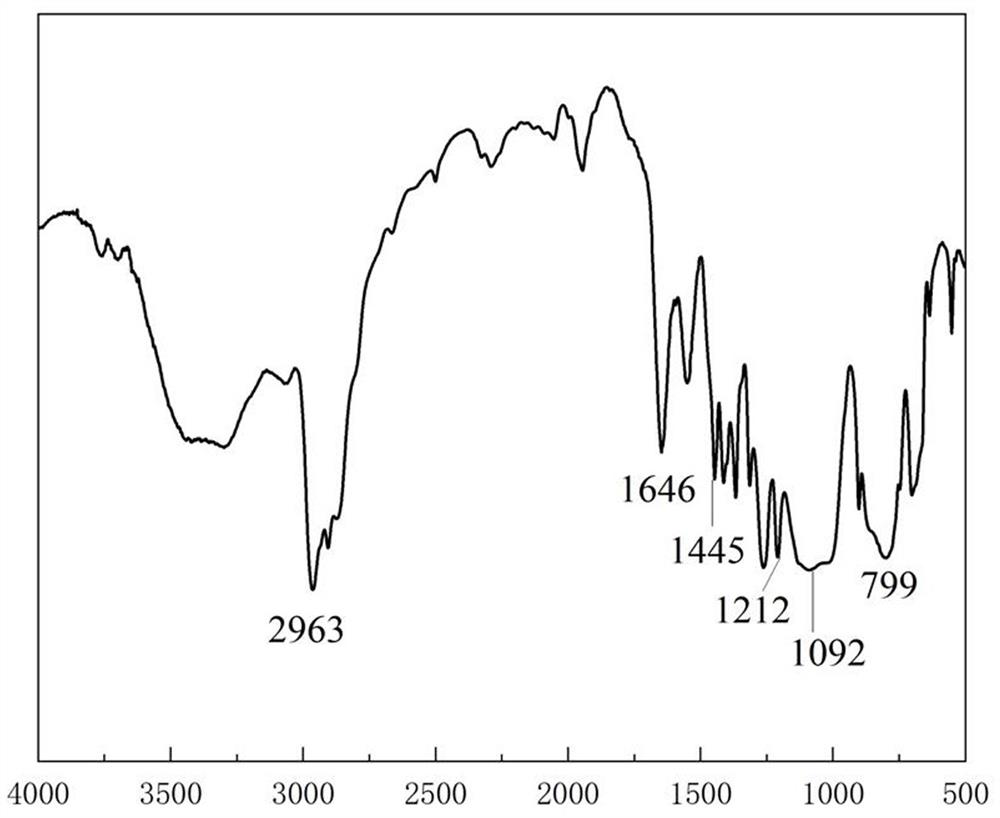

Embodiment 3

[0042] 1. The 200 g of polyether amine ED600, 67.3 g of polyether acid is added to the first reaction vessel with a stirrer and a condensation reflow device, and the condensation reflow device and a stirrer are opened, and 4 g of sub-phosphite, start heating. The temperature rose to 175 ° C, then 4 g of triphenyl phosphite, continued to heat up to 220 to 230 ° C, after 1 to 2 hours of insulation reaction, resulting in an intermediate product I.

[0043] 2. 300 g of octylbarciomethiloxane, 300 g of trifluoropropylcyclo-trilate and 59.7 g of epoxy double head is added to a second reaction vessel with a stirrer to open the stirrer. The temperature rose to 70 ° C, 0.66 g of tetramethylammonium hydroxide, continued to heat up to 95 ° C, after the insulation reaction for 5 h, resulting in an intermediate product II.

[0044] 3. Add 400 g of intermediates II, 80.2 g of intermediates I and 320g isopropanol to a third reaction vessel equipped with a stirrer and condensate reflow device, op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com