Novel artificial board and manufacturing method thereof

A production method and technology for wood-based panels, which are applied to flat products, manufacturing tools, other household appliances, etc., can solve problems such as lack of surface flatness, and achieve the effects of excellent interlayer bonding, tight and reliable bonding, and simple process steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

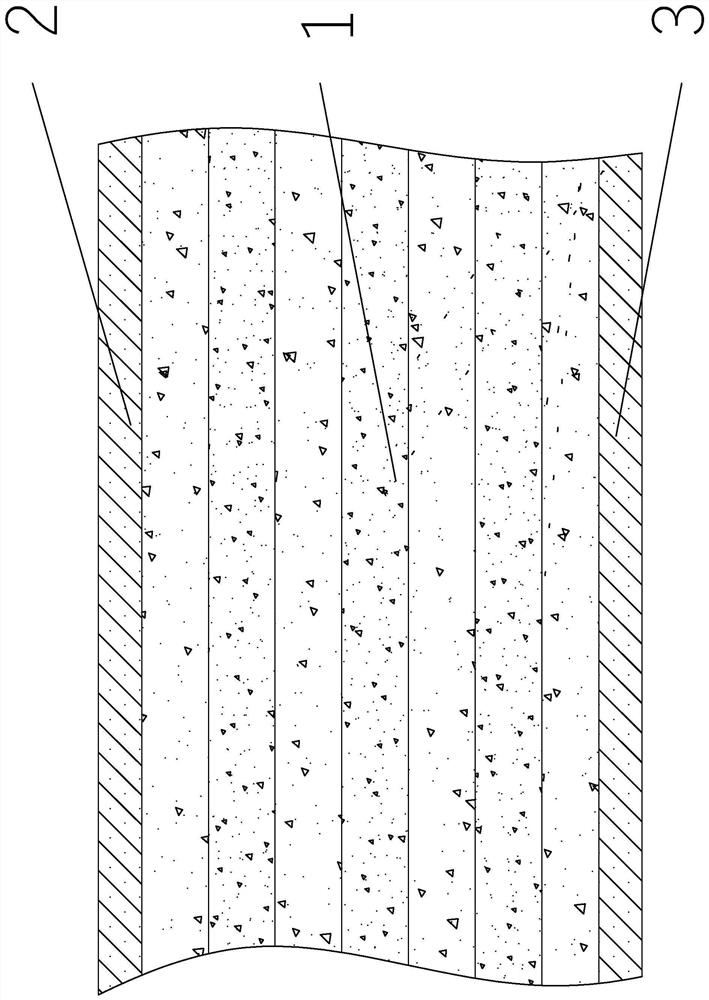

[0023] See figure 1 , figure 1 The manufacture method of the novel wood-based panel shown comprises the steps:

[0024] A) prepare the inner core layer 1, choose preferably to buy from commercial channels but also can be self-made multi-layer plywood with a thickness of 25mm as the inner core layer 1, stand-by, the raw material of the multi-layer plywood described in this step is wood Wood waste generated during processing or wood product processing, the wood waste is any one or a combination of wood shavings, chips, wood fibers, sawdust, miscellaneous strips, miscellaneous pieces, and granular debris, that is, A variety of mixtures, wood waste and formaldehyde-free flame-retardant environmentally friendly adhesives are mixed according to mass percentages of 75% and 25% respectively, and then pressed under high temperature and high pressure and formed after a reasonable period of time. In this embodiment , the formaldehyde-free flame-retardant and environment-friendly adhesi...

Embodiment 2

[0028] The figure is omitted, only the raw material of the inner core layer 1 in step A) is changed to a mixture of wood waste and plant material, and the mixing ratio of the two can be any weight ratio, but the preferred weight ratio is 1:1. The thickness of the inner core layer 1 is changed to 5mm, and the aforementioned plant material is any one or more mixtures of rice straw, bagasse, waste hemp fiber, plant stems and vines; Instead, the mixture of wood waste and plant material described in step A) is thermally ground into a powder material with a 130 mesh sieve, and the moisture content is changed to 10%, and the addition of the adhesive is changed to wood waste 22% of the weight of the mixture with the plant material; only change the temperature of the high-temperature and high-pressure device in step C) to 105°C, the pressure of the high-temperature and high-pressure device to 2MPa, change the natural curing time to 60h, and change the first smooth finish The thicknesse...

Embodiment 3

[0030]The figure is omitted, only the material of the inner core layer 1 in step A) is changed to a tooth joint plate purchased from commercial channels, and the thickness of the inner core layer 1 is changed to 10mm; only the smashing in step B) is changed to For the thermal grinding of woody waste material described in step A) into the powder material of crossing 120 mesh sieves, and the moisture content is changed into 6%, and the addition of adhesive is changed into 25% of woody waste material weight; Change the temperature of the high temperature and high pressure device in step C) to 150°C, change the pressure of the high temperature and high pressure device to 6MPa, change the natural curing time to 48h, and change the thicknesses of the first smooth finish layer I2 and the second smooth finish layer II3 Each changed to 2.4mm. All the other are the same as the description to embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com